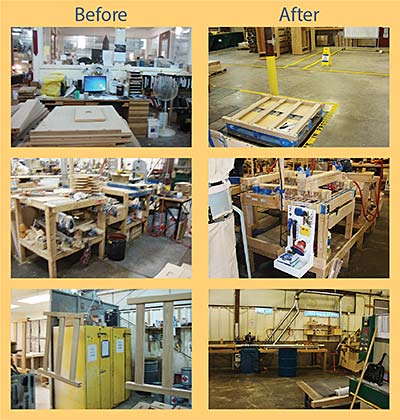

5s Before And After

Unit 12 The Lean Office 5s In An Office Environment Dr John R Thomas Associates

Healthcare 5s Before After

5s Training

Lean Shorewood Shorewood Wi Official Website

Q Tbn 3aand9gcrr8c6hze2ij8vn0lwzqfhcdylmpghuyttq 0cg Cfhzjn2xady Usqp Cau

Environmental Professional S Guide To Lean And Six Sigma Chapter 2 Sustainability Us Epa

As a leader, you must complete a 5S project first in a small area of your world to see the before and after.

5s before and after. Before and after 125. Before / After Expired and mixed items © 10 Karen Martin & Associates Forced rotation;. • Eliminate small imperfections through cleaning and inspecting activity.

Implement the 5S approach to hone in on effective workplace organization & standardized work procedures, reduce waste, increase efficiency & work quality. 4) seiketsu, or standardize;. You can list different metrics related to the marketing performance such as activity metrics, output metrics, and operational metrics.

Disorganized cabinet in a ward at. Fun Introduction to 5S for Lean Manufacturing Training - Duration:. The 5S methodology does provide a framework for cleaning and organizing work spaces but when implemented correctly, 5S can directly impact efficiency and productivity.

Click Here to view more Liposuction Surgery. The Kaizen Before and After Template is simple and effective and can help communicate the results from your Kaizen Efforts. The four bag labels for sorting your clutter are "Throw.

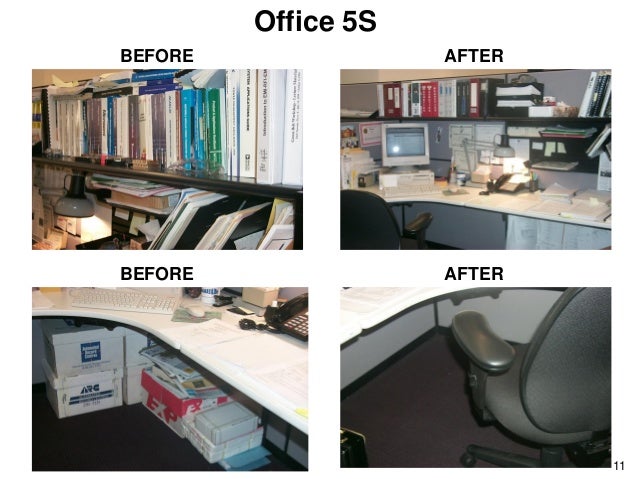

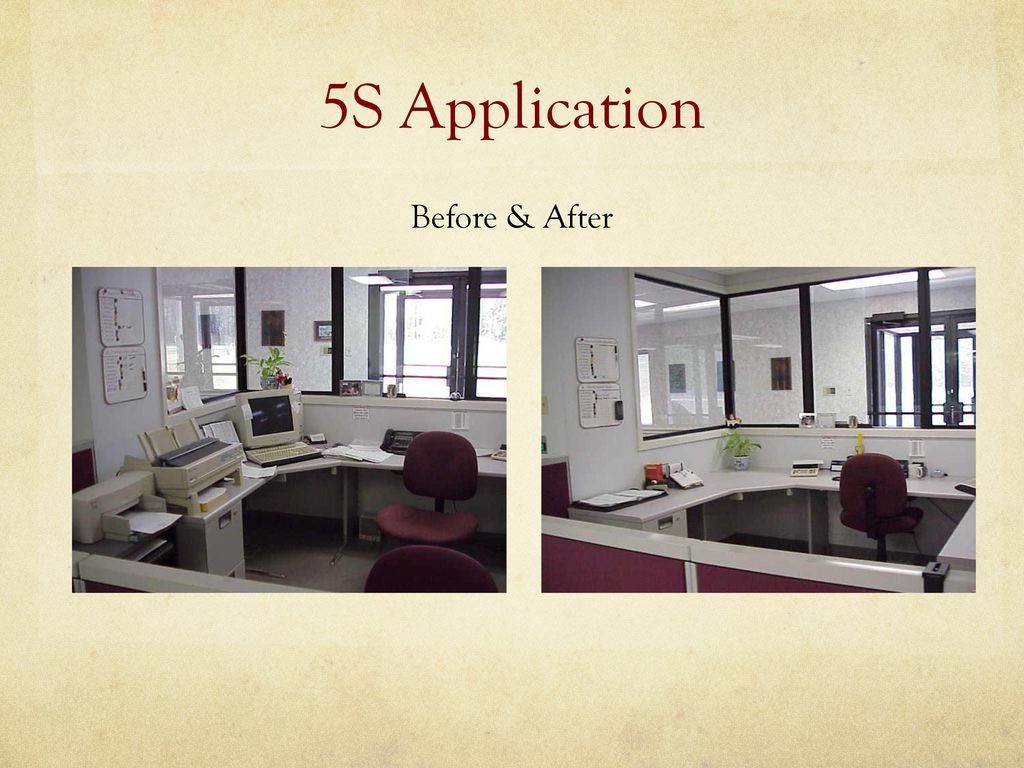

Before and after 127. Before 5S, spaces are cluttered and confusing. Before and after 126.

3 basic rules are:. Organization VWM Organized Tool / Die repair area 5S Example:. 5S is not necessarily the only, or even the best way to initiate lean thinking and practice in an organization.

Retain (keep), return (doesn’t belong on your desk), rid (you don’t even use). How Well is Your Business Doing?. In the modern lab, where many labs have faced reduced budgets and fewer staff members, adopting the lean methodology can result in a more cost-effective and safer way to manage processes.

There are many details that Lean Coordinator must follow to keep league 5S alive and well running. I removed many items that I rarely used. 5S Forms Storage Area Before 5S Forms Storage Area After.

Six months later when you visit the area that was the focus of the 5S event, it has reverted back to the “old” unorganized state. 5S in the workplace. Many manufacturing facilities have opted to follow the path towards a “5S” workplace organizational and housekeeping methodology as part of continuous improvement or lean manufacturing processes.The term refers to five pillars:.

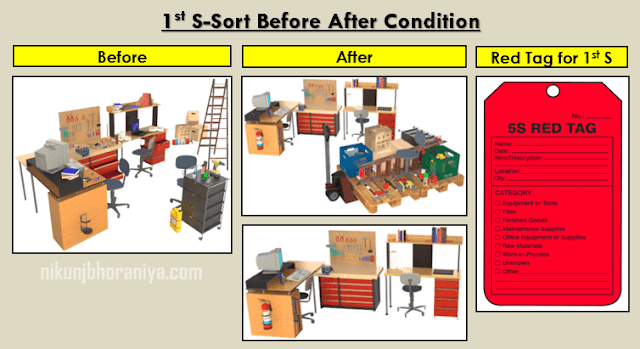

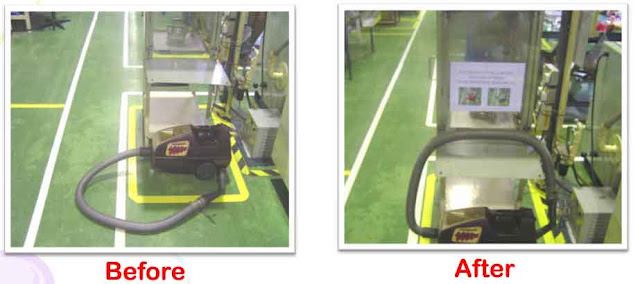

After 5S, everything has an assigned place, which is often marked with floor marking tape, labels, and other visual cues. Remove all items not needed for current production operations. Before you decide to implement 5S The many positives of 5S are well-documented.

The 5S system is a powerful lean manufacturing tool with the potential to improve productivity and profitability. 5 SHINE To clean and inspect the workplace thoroughly so that there is no dirt on the floor, machines and equipments. Sort, Set in Order, Shine, Standardize, Sustain.

6S may appear to focus on a workplace—sorting, straightening, etc. Before After 5S Example:. 5S Before and After Board.

Use a four-bin or bag system. For a large, printable version of any image on this page, please right click and choose Open Image in New Tab.Please only print or save images for your own use. 5S is a Lean concept that contains five components;.

We must achieve safety increasing, profitability and a reduction in operating costs. The 5S program must be re-enforced. Here’s how to apply 5S to your home office desk, the next post in our How to Apply 5S series.

Develop a plan, activity chart and distribute responsibility. Cutting tools of integrated manufacturing systems laboratory before and after the 5S implementation. Sort, Set, Shine, Standardize, and Sustain.Success stories, like Toyota’s, have inspired many companies to implement 5S as a means to become lean, yet many of those attempts end in failure.

And i am happy reading your article. Engage in the 5S Process to Learn the Value of 5S 5S is not just for others to follow. It was dark when I woke.

This is a ray of snsuhnie. Sort-Eliminate the unnecessary items from your desk by placing everything into three piles;. Following the first 2Ss (Sort and Set in Order) of the 5S process, you will be faced with difficult choices.

You will want to create a schedule for your 5S System with daily and monthly activities. 2) seiton, or set in order or systematize;. Before and after 124.

August 5, 11 at 10:46 pm. If you have recently transitioned from conventional to digital marketing, then this is the right place to show the impact that it had on the company’s performance. Boundary lines designates proper location.

Before and after 119. Here are some examples of 5S & Lean Improvements so far in the organization we have provided the Consultancy, hope it will help you all in drawing some refer. After 5S (10) Use labeling and organize items lead to minimize time for searching items, easy to control stocks.

Reduced work in process. Tool Shadow Boards - Before & After Great 5S - Sort, Set in Order, Shine and Standardize. It sure could use some organization!.

5s Implementation Plan Step 1:. However, this process can also be used for home as well for getting--and staying--organized. The change between the first and second survey in-creased from a total average of 3.46 to 4.54.

Jun 28, - Explore Лучия Карагьозова's board "5s" on Pinterest. And, go here for a funny perspective on the feelings before and during a Kaizen event. Reduced square footage usage.

A properly handled 5S strategy will not only eliminate waste but also help improve the day to day jobs of every employee. Before and after 122. The premise of 5S is to help organize and improve the work conditions of a workplace.

Simply put, 5S Lean is an enabler of waste-free production that supports an operating philosophy that emphasizes discipline, efficiency, and attention to detail. Step 1 Sort to get everything in your home up and out of the place of clutter. Before and after 118.

By documenting their situations before and after adopting 5S, many facilities have been able to show actual, measured improvements. 5S isn't just about cleaning up, though. At first you may have to draw these examples from the Internet or companies whose programs you’re emulating.

When implementing 5S many companies find that there is initial resistance from the front line employees, but after each area is organized, cleaned and optimized the way it should be, they are quite happy. Before 5S (09) Disorganized items in the store. October 31, 19 March 21, 19.

TRAINING, WELL INFORMED EMPLOYEES and PROPER AWARDING SYSTEM. Browse the 5S images on this page for examples of 5S in action, before and after photos, and more. Recognize achievements, both individual and departments.

If you answer yes to any of the following questions, you may find 5S really useful and effective:. Nothing speaks louder than a photograph. • Clean the work area – share the work load among the group.

The 5-day 5S event ends with a lot of “lip service” that 5S will be maintained. I needed to first sort through everything that was on my desk. Why doesn’t 5S sustain?.

Choosing a pilot or target process, and then beginning with standard work, can logically lead to value analysis and the application of other lean tools, including 5S. 12 x 575mm (3mm thick) with 8 x displays. A place for everything and everything in its place.

The analysis of the survey proofs that the 5S imple-mentation project was a success. Before and after 5S 5s lean before after - Google Search Web Page Under Construction. Sustain (Shit-shuke) The final and important step is to sustain the changes and improvements brought thorough implementation of 5S.

Goal was to increase productivity in their Paint area. The goal of standardization is to put in place a system to support your 5S System. Often, after a period of grace, bad habits resurface, and all the hard work done goes out of the window.

A missing barre l is not obvious. Whether it’s before-and-after pictures or testimonials from users who have already completed a 5S project, there’s plenty of compelling evidence about how effective this discipline can be. July 19, 11 at 11:12 pm.

By this time you have prepared your 5S System plan and have established your 5S team. The first answer is the lack of infrastructure to support Lean and therefore 5S. Factory Systems has practical experience and regular assignments in the field to enable you to embed the new techniques introduced by the 5S in new working practices.

Just a little before and after video of our storage warehouse at work. 1) seiri, or sort;. These items included my GoPro, Xbox, school.

The 5S Before and After Board is intended for use with both the 5S Sorting Event Wizard Event Boards and the TED 5S Continuous Sort System. Post before and after pictures, a schedule of activities, individual and team winners of 5S contests, and an overview of the system. Defining the work method in a process provides a framework for.

Respondents answered the survey. When 5S is used in the workplace, it's easier to detect abnormalities and spot potential problems before they grow into significant issues. The pictures can be used to sustain the 5S System as examples of the improvements.

Example of 5S activities. 5S Before and After Board The 5S Before and After Board is a very important tool for. See more ideas about Lean manufacturing, Lean six sigma, Kaizen.

21 Paint 101 Thinner 0 Paint 101 Thinner 0 Paint 101 Thinner 0 These barrels should be here. 6 STANDARDISE To maintain a high standard of workplace organisation by keeping everything clean. 3 Comments to BEFORE & AFTER:.

Before and After 5S. The area in which people work, but this is not correct. • Take “after” pictures – use photographs to demonstrate your results.

5S Penile Enlargement (Before/After) Click Here to view more 5S Penile Enlargement Surgery. Before you start take pictures of workstations before and again after the sort so you can post them on your 5S bulletin board. Took long time to searching items needed:.

Here’s a photo of my desk before applying 5S. For example, the University of Georgia started a lean program in 09. If not read How to Plan a 5S System Launch.

The management should identify ways like having documents in place for 5S steps, scheduling audits in surprise, recognising and rewarding teams for sustained 5S work place etc. Lean Smarts 63,4 views. (Throw a pizza party, post results of achievements in public areas.) Set your goals, monitor them and “raise the bar” when necessary.

In addition to 10 to 15 minutes for Seiso everyday, owners should have a weekly 5S time, or monthly 5S day. Generated a whole wall of Post-its identifying problems. Visual Management Tool Stand Lean Manufacturing Lean Six Sigma Dental Supplies Kaizen Working Area Sorting.

• Take “before”pictures – a record of your current state often generates the motivation to keep things clean. 5S rests on five “pillars”:. Do not be mislead by the before and after photos that everyone doing 6S produces.

And 5) shitsuke, or self-discipline or sustain. I think this is among the most vital information for me. One of the drawbacks that appears in this methodology implementation is the necessary investment justification to authorize the project.

Learn more about how Toyota Forklift is always looking for ways to enhance safety and increase efficiency and productivity in this article. Cart after back to 5S examples. The researcher has also included before and after figures for the reader to get a better.

The Kaizen Before and After Template has 5 main parts. Marketing Performance Before After Slide. Our cartoons above help illustrate how 5S can benefit your organization.

They are valuable portrayals of measurable improvements, but they rivet attention to the workplace and, in that sense, they can mislead. Aside from the 5S before and after pictures, there's some insightful comments during the closing session (start at 7:13 in the video). Before you get started, let’s perform a test.

The tenets are seemingly simple and straight-forward:. Using 5S, they reduced the travel distance for processing supplies by %, saving $7,000 to $10,000 in labor each year. BEFORE AND AFTER PICTURES.

5S is more than just an organization strategy.

Portland Volunteers Using Lean And Six Sigma To Improve Community Enterprize Excellence

Learn More About 5s Methodology And Its Benefits

How To Adopt 5s In Fmcg

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

5s At Global Pak

Evolution Of The Area Before And After The Implementation Of 5s Download Scientific Diagram

Some Images Of 5s Houskeeping In Factories Total Quality Management

Visual Workplace 5s Supply Blog Page 3

Consolis Awarded For Its Digital Communication Consolis

5s Work Flow Management In Enterprise Excellence Deployment Bpminstitute Org

5s Organization Lean Into Living

Opep 5s In Manufacturing

5s Events And Continuous Improvement Beckman Coulter

What Is The 5s System Definitions Core Concepts Principles Graphic Products

5s System Singapore Seiri Seiton Seiso Seiketsu Shitsuke

Office 5s Before After Before

5s Methodology Implementation Benefits Case Study

Implementing 5s As A Branding Strategy Biztorming Training

5s Photos Before After 1 Lean Manufacturing Update

Applying 5s Series Part V The Last Two S Seiketsu And Shitsuke Reliable And Efficient

5s Lean Manufacturing And Six Sigma Definitions

The 5s System Lean Manufacturing Methodology

Importance Of 5s In Making The Earth A Better Place

Before After 5smanagement Com

5s Work Flow Management In Enterprise Excellence Deployment Bpminstitute Org

Q Tbn 3aand9gctk7czsrtipbysm2adewltksxgafvvaphb03vrbe Rw9ruf2kys Usqp Cau

Before After 5s Activity 5smanagement Com

5s Or 6s What S The Safe Choice

5s Education Training Lean Methodology In The Office Ppt Download

Untitled Document

Analysis Of Lean Manufacturing Implementation In Smes A 5s Technique Springerlink

5s Images Library See What 5s Looks Like In Action

The 5s System Lean Manufacturing Methodology

Lean Healthcare Transformation Case Studies Gbmp Gbmp Healthcare

Environmental Professional S Guide To Lean And Six Sigma Chapter 2 Sustainability Us Epa

5s Workplace Organization Ut Center For Industrial Services

Imcg Consulting 5s Lean Productivity Methodology

Q Tbn 3aand9gctxeptrxapxfgjnzxw9jyzbgwjewqjh4 Cj6vj0hvf9ddnesh09 Usqp Cau

Shelf Arrangement A Before 5s Improvement B After 5s Improvement Download Scientific Diagram

Skyepharma Adopts Lean Production Methods For Right First Time Customer Satisfaction

Why Your Workplace Should Include A Flexpipe Crib Flexpipe

Before And After Professional Garage Organization Using The 5s Japanese Organization Method Garage Organization Converted Garage Garage Renovation

Graniterock 5s At Graniterock

5s Basic Training What Is 5s And Why Do We Want To Do It Ppt Video Online Download

Extreme Makeover Storeroom Edition Life Cycle Engineering

5s Good Housekeeping Techniques For Enhancing Productivity

5s Lean Manufacturing And Six Sigma Definitions

Best 5s Before After Images Kaizen Lean Manufacturing Lean Six Sigma

Conference Room 5s Before After

Table 1 From Application Of Lean Manufacturing Tools In The Food And Beverage Industries Semantic Scholar

Leanfit Lean Management Before And After Lean Management 5s Floormarking Leanmanufacturing Makeinindia Swachhbharat Glitteringyourassiduous Leanmanagement Engineering Consultancy Controlpanels Automation Cashflow Menpower

A Similar Lean 5s Tei Transformation Can Happen To Your Shop Floor

Lean 5s In Msicu Youtube

The Illusion Of 5s In Sciences That Are Based On By Ha Thuc Tien Medium

Icru Before And After The Application Of The 5s Method Download Scientific Diagram

5s Lean Before After Google Search Visual Management Kaizen Lean Six Sigma

The 5s System Lean Manufacturing Methodology

5s Case Study Using Toyota S 5s On A Farm The Lean Farm By Ben Hartman Book Review Econoshift Com

Extreme Makeover Storeroom Edition Life Cycle Engineering

Www Ijstr Org Final Print Feb15 Implementation Of 5s Quality Tool In Manufacturing Company A Case Study Pdf

Http Www Intracen Org Uploadedfiles Intracenorg Content Exporters Exporting Better Quality Management Assetpdf Bulletin eqm 5s Pdf

5s

5s Images Library See What 5s Looks Like In Action

Lean 5s In Msicu Youtube

5s Archives Rock West Racing

5s In Plant Ops Lean At Waterloo University Of Waterloo

Some Images Of 5s Houskeeping In Factories Total Quality Management

New Year S Resolutions 5 Get Organized Chi Solutions Inc

5s More To Shine Than The Surface Think Op Ex

Implementing 5s Workplace Organization And Standardization

Best 5s Before After Images Kaizen Lean Manufacturing Lean Six Sigma

Implementation Of 5s In Apparel Industry Ordnur

5s Lean Manufacturing And Six Sigma Definitions

3 Top Ways A 5s Event Brought Order To Our Metal Fabrication Shop Wiley Metal

Implementation Of 5s In Apparel Industry Ordnur

5s Colorado Department Of Transportation

5s A Workplace Organization Me Simplebooklet Com

Lean Laboratory 5s For The Laboratory

Lean 5 S Www Vergoton Com

Free Go Getter Membership Share Your 5s Before And After Photo

Best 5s Before After Images Kaizen Lean Manufacturing Lean Six Sigma

Lean Manufacturing Supplies Home Facebook

Efforts For Safety And Health Health And Safety Csr Muratec Murata Machinery Ltd

Leanfit Lean Management Before And After Lean Management 5s Floormarking Leanmanufacturing Makeinindia Swachhbharat Glitteringyourassiduous Leanmanagement Engineering Consultancy Controlpanels Automation Cashflow Menpower

Some Images Of 5s Houskeeping In Factories Total Quality Management

The 5s Approach To Improve A Working Environment Can Reduce Waiting Time Findings From Hospitals In Northern Tanzania Emerald Insight

3 Ways Your Organization Can Undertake A 5s Audit Izimage

Mount Pleasant Shines After 5s Event

S3 Amazonaws Com Assets Highways Gov Uk Specialist Information Knowledge Compendium Visual Managementvisual Controls Implementation Pilot 5s In Highways Construction And Maintenance Pdf

27 October 13 Patience To Dominate

Leanfit Lean Management Before And After Lean Management 5s Floormarking Leanmanufacturing Makeinindia Swachhbharat Glitteringyourassiduous T Co Hpvupfxsku

5s Day Getting And Staying Organized Kent State University

5s Events And Continuous Improvement Beckman Coulter

Q Tbn 3aand9gcswl23ynci4kdwwlgw2s4saghdxfk1kxojl0wt Ea6dk8dqfjd Usqp Cau

How The Initiative Of Nurses Transformed A Whole Department Planet Lean

Before And After 5s Lean Manufacturing Business Process Management Process Improvement

5s Archives Page 2 Of 2 C Tek Lean Solutions Inc

Evolution Of The Screening Area Before And After The Implementation Of 5s Download Scientific Diagram