5s Vs 6s Lean

3

Lean Videos

Lean 5s Six Sigma Safety Science

Q Tbn 3aand9gcrgqqwb2oknxiafyyazejncixf5evgv9umj7qc7rseckrvjzj7m Usqp Cau

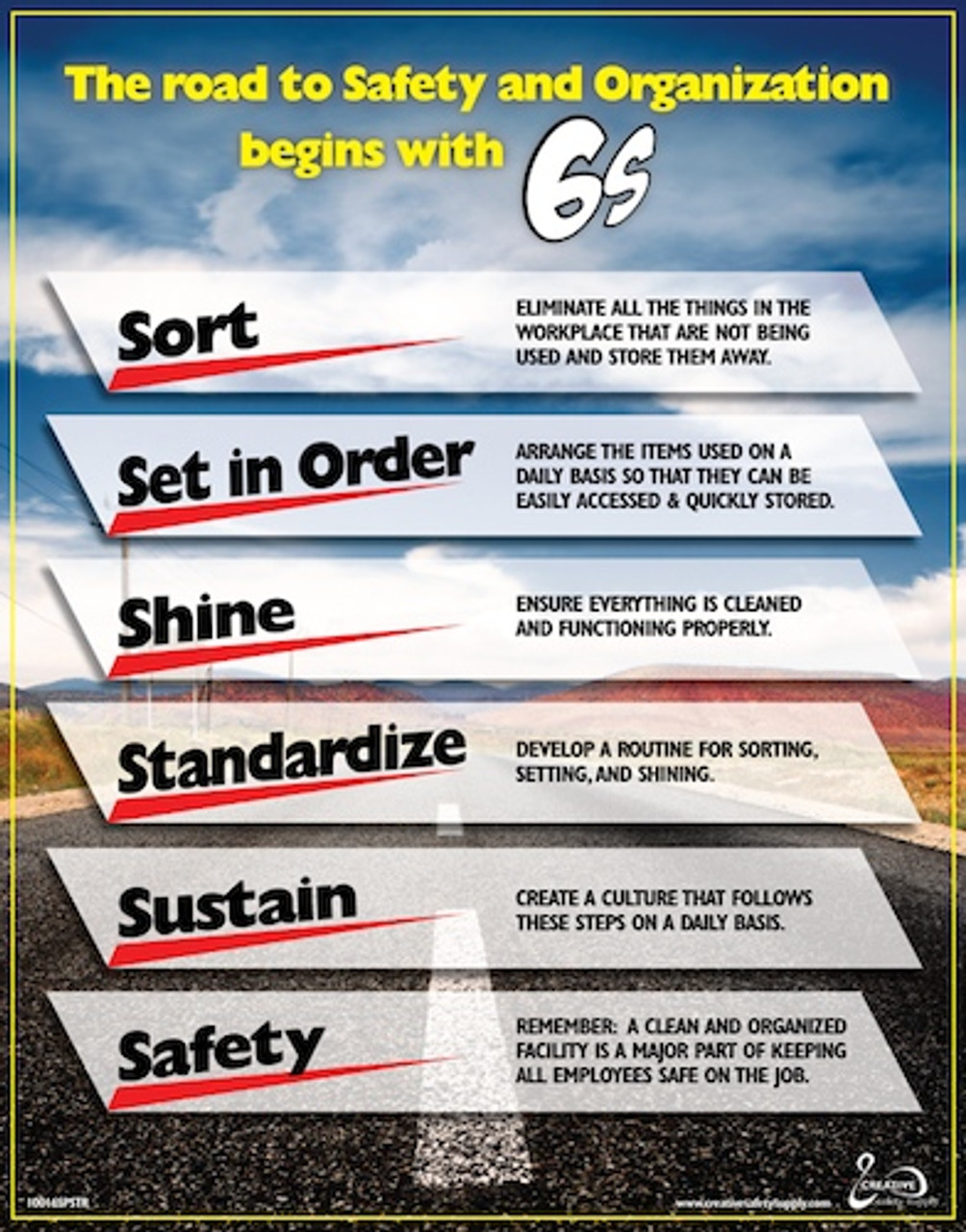

6s Poster 6s Lean Workplace Health And Safety Poster Lean Sigma Lean Manufacturing

5s Lean Manufacturing And Six Sigma Definitions

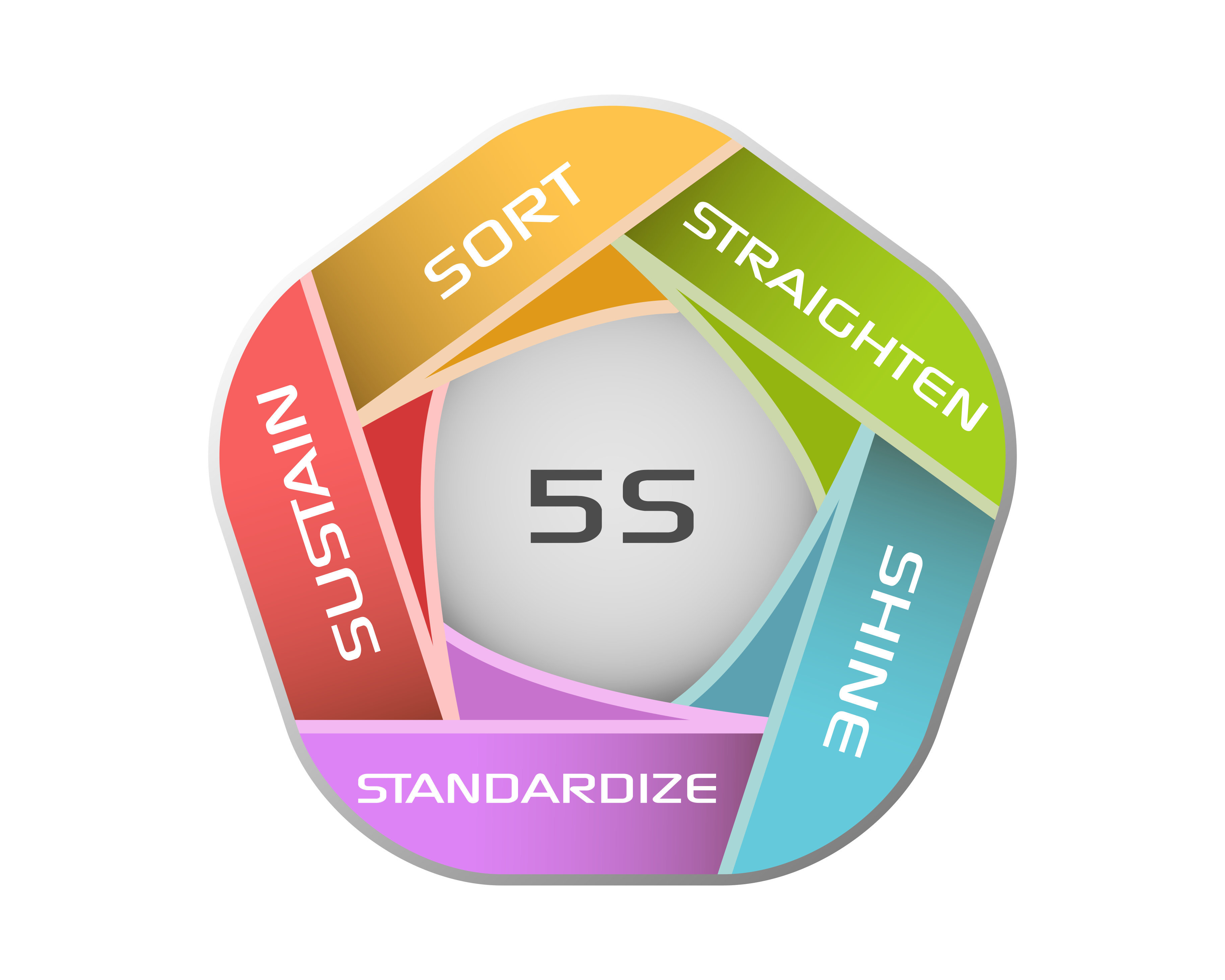

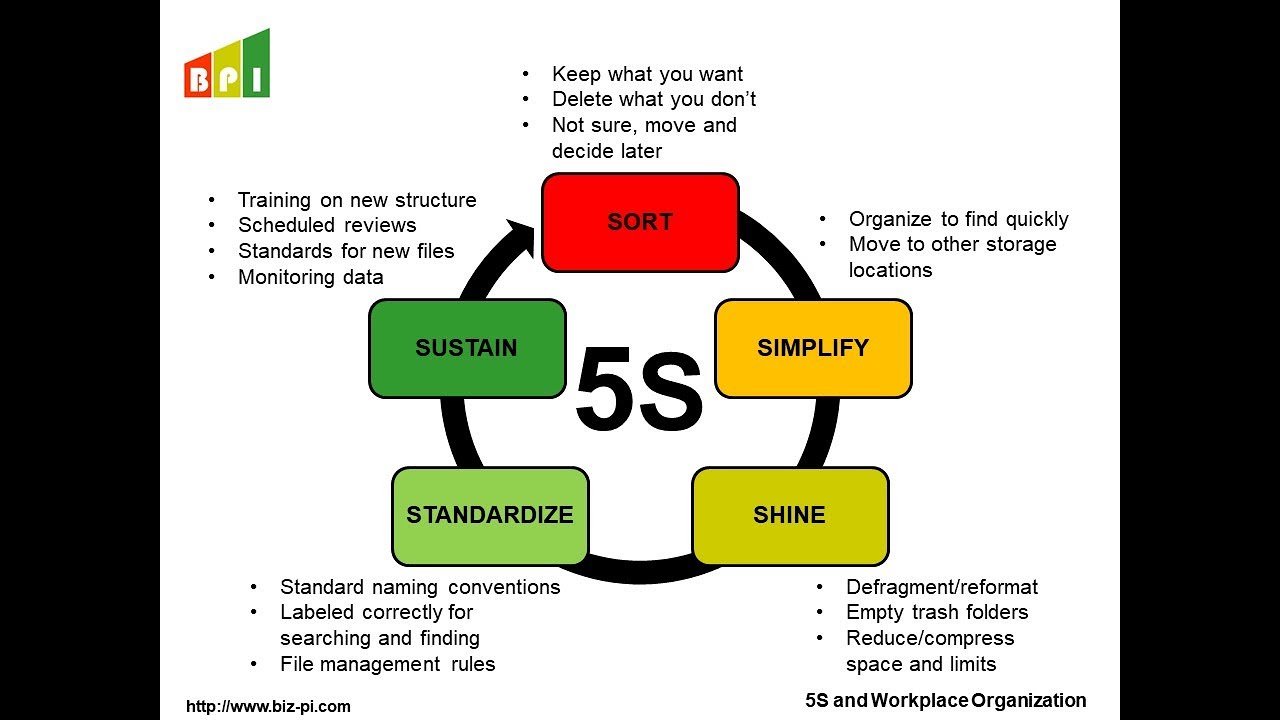

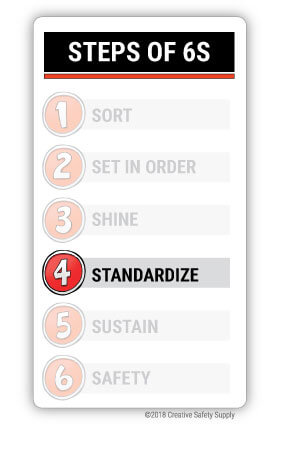

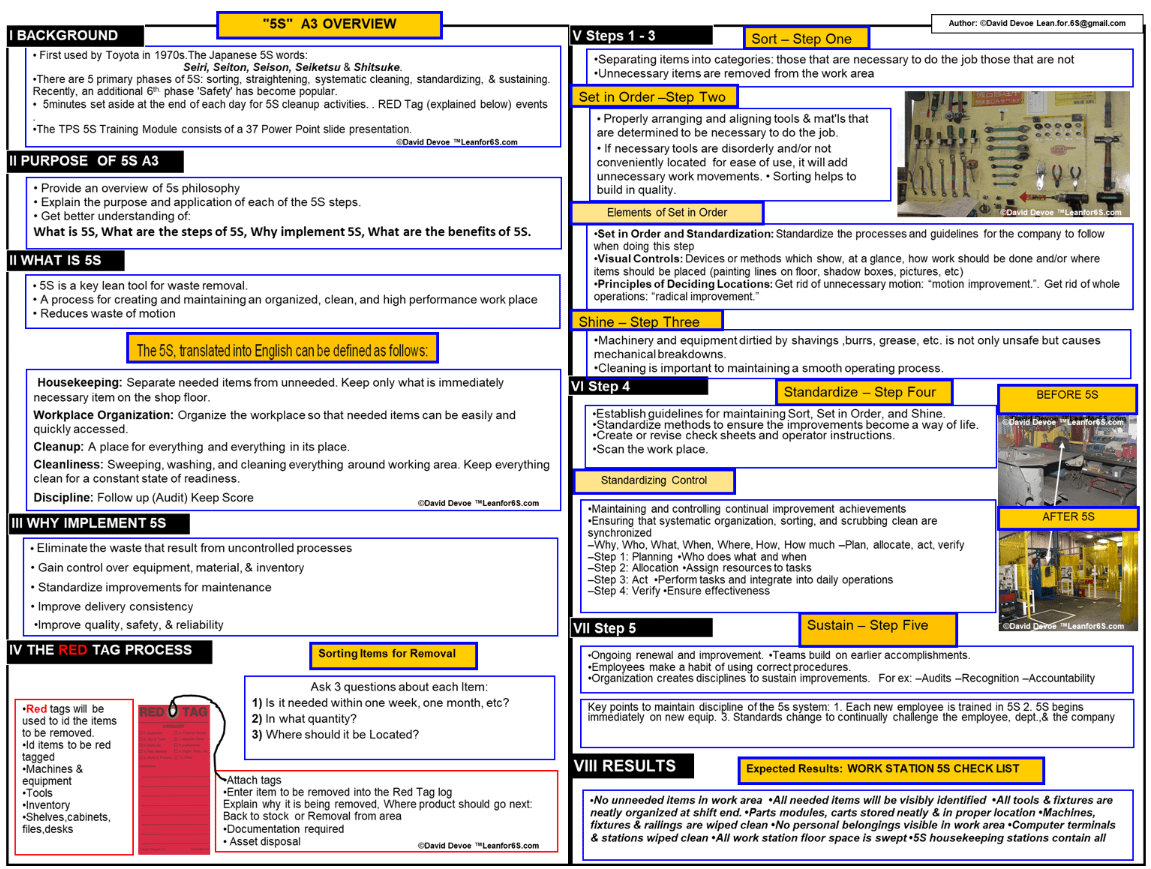

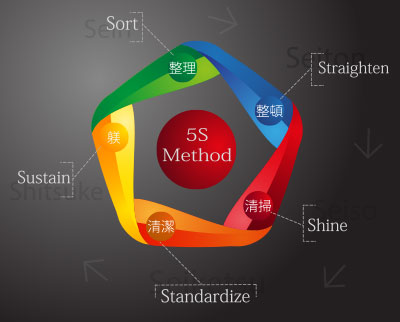

For those not exposed to the 5S lean manufacturing tool, it stands for sort, straighten, shine, standardize, and sustain.

5s vs 6s lean. Using 5S reduces waste (a fundamental goal in lean manufacturing), improves safety (see our article on Lean 6S Safety), and otherwise improves your production process and work environment. Another argument I have heard is that the 5S alone is a “fix it” only mindset. 5S Lean Manufacturing and JIT Management.

The 5s standard is primarily used in manufacturing facilities to help improve efficiency and safety in the work environment. This can be an important addition to some facilities, and some might not need it. See Exhibit 1), addresses just the situation I described.

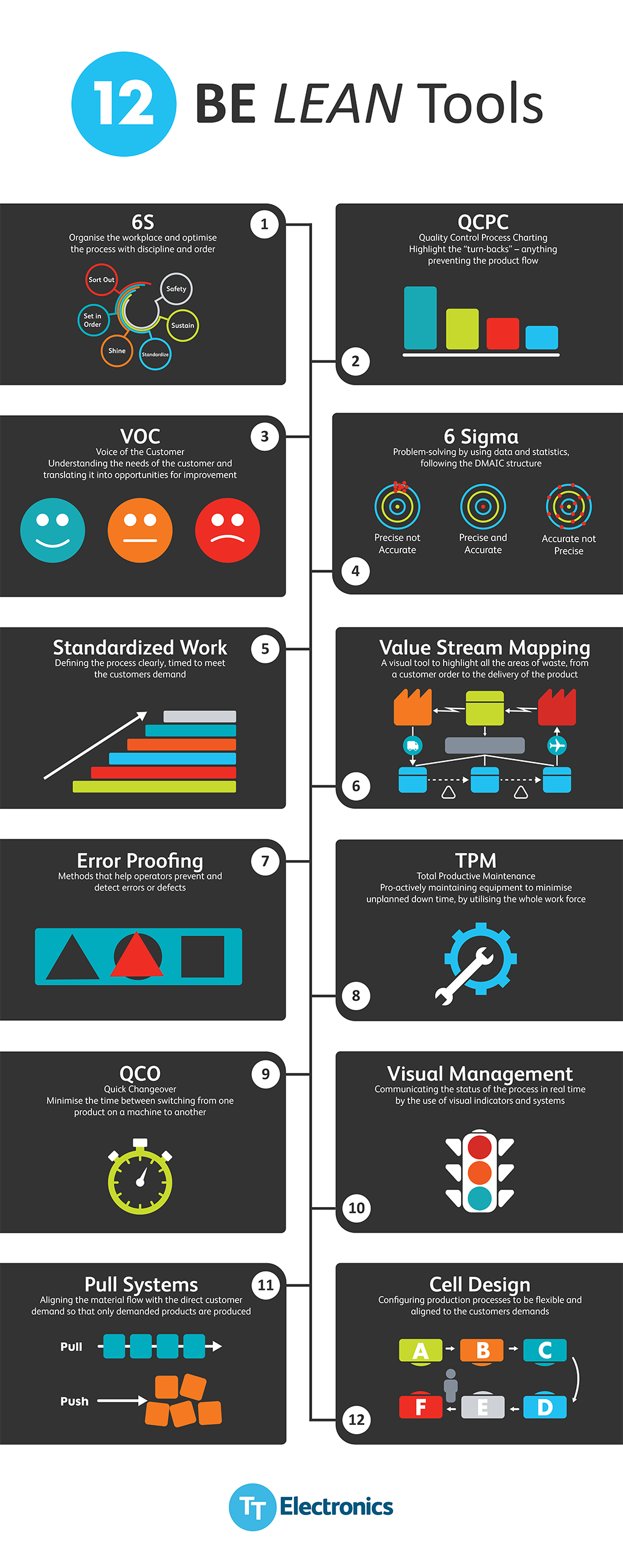

6S Methodology in Lean Manufacturing. Dan Davis of FMA Communications, writing for The Fabricator, says 5S is not a program but a commitment to an orderly work environment. Tools, 6S (originally labeled 5S;.

As with all Lean tools, 6S is about eliminating waste and maxi-mizing value-added work. Die jährlich durchgeführte Gallup-Studie zum Engagement-Index zeigt:. Not to be confused with Six Sigma (often written as 6s).

5S typically denotes the level of cleanliness, organisation and ergonomics that have been considered and built into the workplace. This method helps an organization to remove items that are unnecessary. 5S is based on the CANDO system developed by Henry Ford in the early th century.

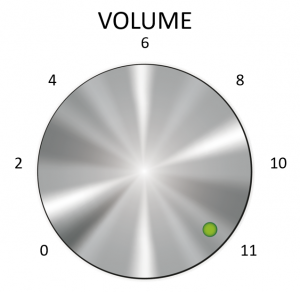

What is better for you?. 5S but it will hopefully give facilities the information to decide whether or not updating their own implementation is a good idea. When everyone else’s had a volume knob that went from 0 to 10, his went up to 11.

*FREE* shipping on qualifying offers. 6S (an update to 5S) is a foundational Lean concept that is designed to improve organization, eliminate waste, and increase safety in your facility. It's designed to help build a quality work environment, both physically and mentally.

Follow Us • 978-842-4610 • Contact Us. They feel that safety should always be on the forefront of daily activities and having a 6S over a 5S plan is essential to doing so. So a 6th S is good.

6S may stand for:. Sort (Seiri) Separate required tools, materials, and instructions from those that are not needed. One of these tools, 6S (originally labeled 5S;.

The output of engineering and design in a lean enterprise is information, the theory behind using 5S here is "Dirty, cluttered, or damaged surfaces attract the eye. The difference between 5S and 6S is that the 6th “S” stands for safety. Quality improvements, productivity gains, better safety awareness, and a safer workplace.

As with all Lean tools, 6S is about eliminating waste and maximizing value-added work. It is the foundation of Lean, Visual Controls and where many organizations begin their Lean adventure. 5S is a system to reduce waste and optimize productivity through maintaining an orderly workplace and using visual cues to achieve more consistent operational results.

It is a lean process improvement tool that stands for Sort, Set in Order (aka Straighten or Stabilize. Register / Sign In • Track Order. The 5S boasts an 8MP rear sensor, but the 6S comes packing an improved 12MP version.

Es ist höchste Zeit, etwas für die Mitarbeiterbindung zu unternehmen!. From a resource use 6s will allow more focus on safety auditing w/ out requiring more “formal” safety audits (which we currently do). Over time, people have modified 5S by adding a new “S” to create 6S systems.

I think it would be great if you talked about different consultant companies and their processes. There are several different types of lean standards but when used with 5s it is typically lean manufacturing that people are thinking of. The process behind 5S began decades ago in Japan as a means of ….

The 6S Cycle Floor Sign helps remind employees of the Six Sigma Methodology, in order to increase efficiency and productivity within the workplace. It is also referred to as 6S or 5S+S (adding Safety or Security) or even 7s (adding Spirit and Safety). It is a method used for organizing the workplace in such a way that it can help to give maximum efficiency.

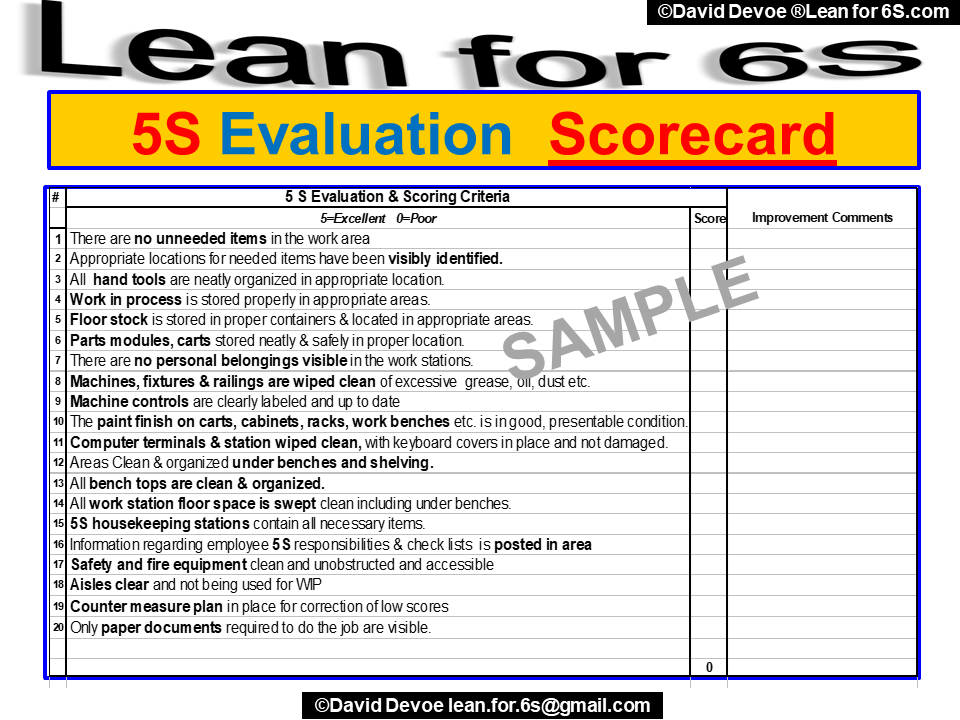

Auditing the safety factors of an area while simultaneously auditing the 5s makes smart use of a trained set of eyes that are already in place reviewing the areas condition. In lean product and process development. It is one of the most widely used and fundamental components of Lean Manufacturing.

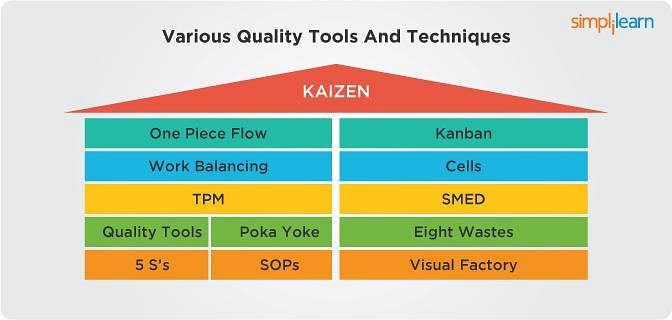

5S lays down a strong foundation for future Kaizen activities. Most people may think of it as relating to manufacturing workplaces, but it is just as applicable to office settings. Credits to original up-loader:.

The 5S Store 16 Lomar Park, Unit 8 Pepperell MA. In certain groups, 5S is becoming 6S, often the 6th component being safety. 6S (music), key signature of six sharps 6S (radiative transfer code), a computer program that simulates the reflection of solar radiation 6S / SsrS RNA, the first noncoding RNA to be sequenced;.

5S is a formulaic method you can use to straighten and organize a work area. While a space is cleaned and organized with 5S. However, with the extra emphasis placed on safety in the past years, there has been a tendency to stress the sixth “S”—that of Safety.

Two expressions were born from that emphasis—6S and 5S+1. The 5S system is often a starting place for implementing lean operations. As the name implies it has five words starting with “S”.

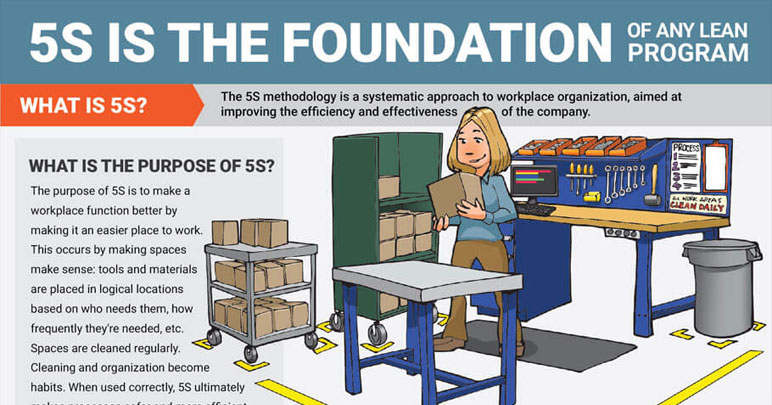

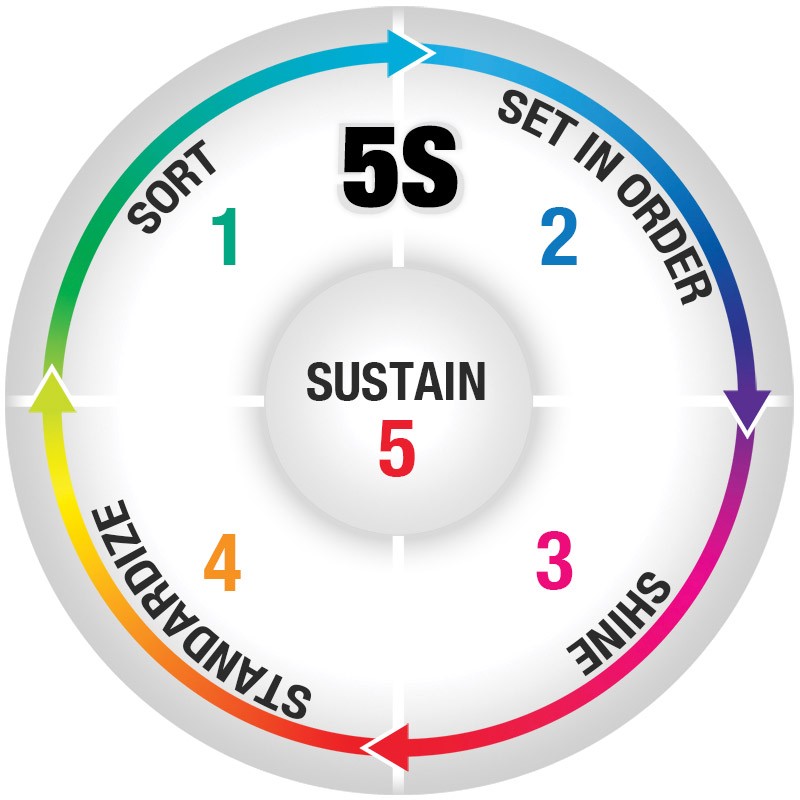

Five S’s (5S) 5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. The philosophy of 5S represents a way of focusing and thinking in order to better organize and manage workspace, specifically by eliminating the 8 Wastes as defined by the Lean Manufacturing system. 5S (or 6S) technique explained 5S (or 6S) denotes 6 key steps in process improvement:.

Novaces, it turns out, is a consultancy apparently based out of New Orleans. 6S (otherwise known as 5S + Safety) is a system that aims to promote and sustain a high level of productivity and safety throughout a workspace. Much of the tech from the 6 has been carried over too, things like ultra-pixels that let in more light.

But by implementing a 6S plan, you move to a “solve and prevent it” mindset which helps continue a road to continuous improvement. Nowadays, safety is at the forefront in the majority of industries. The 5S is a lean method for workspace optimization and one of the foundations of Kaizen.

It consists of 5 consecutive steps that allow any team to organize their workplace for maximum process efficiency. Besides a particular stand-alone technique, 5S is often considered as a component of the wider construct referred to as visual control, visual work environment, or visual manufacturing. The whole point is to reduce or keep out waste, and the method that helps you with that is called 5S.

What are the Five S's (5S) of Lean. Regardless of which term you choose to use, though, be sure to make sure safety is an integral part of your workplace organization efforts. You’ve discussed 5S but Novaces, for example, has a 6S system.

Die 5S/6S – Methode, zum Beispiel in Verbindung mit einem SMED-Workshop, kann auch als Einführung einer Lean-Philosophie im Unternehmen dienen. Based on this success, they expanded their 5S lean approach to include a 6th "S" for safety. 5S has become 6S, the sixth element being safety.

When it comes to comparing 5S vs. That said, it makes a good deal of sense to use 6S vs. 5s is a methodology used in lean manufacturing process.

One of the most common of the 6S systems results from adding Safety to 5S. 6S “It’s one louder, isn’t it?” When I originally wrote that headline, I thought of that wonderful scene on This is Spinal Tap where the musician was talking about how his speakers were louder than anyone else’s. 5S is a workplace organization method that uses a list of five Japanese words:.

6S Cycle – Floor Sign. Remove everything that is not. All these words are of Japanese origin.

This is sometimes called 5S+, 6S, lean 6S, 6S safety, or lean 6S safety. 5S establishes an organization system in which everyone in the workplace participates to remove clutter and set spaces efficiently. High-performing processes and workplaces are always characterized by organization and cleanliness.

Detailed up-do-date specifications shown side by side. Stop the Spread of Germs This infographic describes best practices established by the CDC for restricting the spread of respiratory illness. Staight left an interesting post on The Whiteboard a couple of days ago:.

5S (or 6S) is a lean diagnostic technique (developed as a quality management methodology in Japan) aimed at optimization of the workplace environment and efficiency of work performance. Seiri, Seiton, Seiso, Seiketsu, Shitsuke and Safety (Tran, 16). If a facility finds that they can operate more efficiently and more safely with 6S than they can with 5S, it is clearly the smart choice.

Most people may think of it as relating to manufacturing workplaces, but it is just as ap-plicable to office settings. For Six Sigma, 5S can be invaluable for reducing waste. This 6S Lean Workplace List Poster is a full color high quality poster will help with the daily 6S reminder.

See Exhibit 1), addresses just the situation I described. 5 S is a system or method that helps companies to organize and increase their productivity, helping them to produce quality products faster, in a structured manner and in a way, that maintains their organized working environment while using visual. However, the Fenix 6s pro has a longer battery life than the 5s plus, thanks to the new battery saver management feature that elongates its battery life a little longer.

5S is the Foundation of any Lean Program This infographic outlines what 5S does and how to implement it without headaches or hassles. Learning more about what 6S is, what it stands for, and why it can help you will benefit your business. Kaizen is built on a 5S framework with elimination of waste and standardization at the forefront.

Methods of implementing lean manufacturing include 5S and, more recently, 6S. 6 S lean not only helps organizations promote efficient working environments but also establishes a sustainable culture of safety. Just like 5S, the 6S System asks workers to clean around work stations, while also making sure to put safety at the forefront of every decision they make.

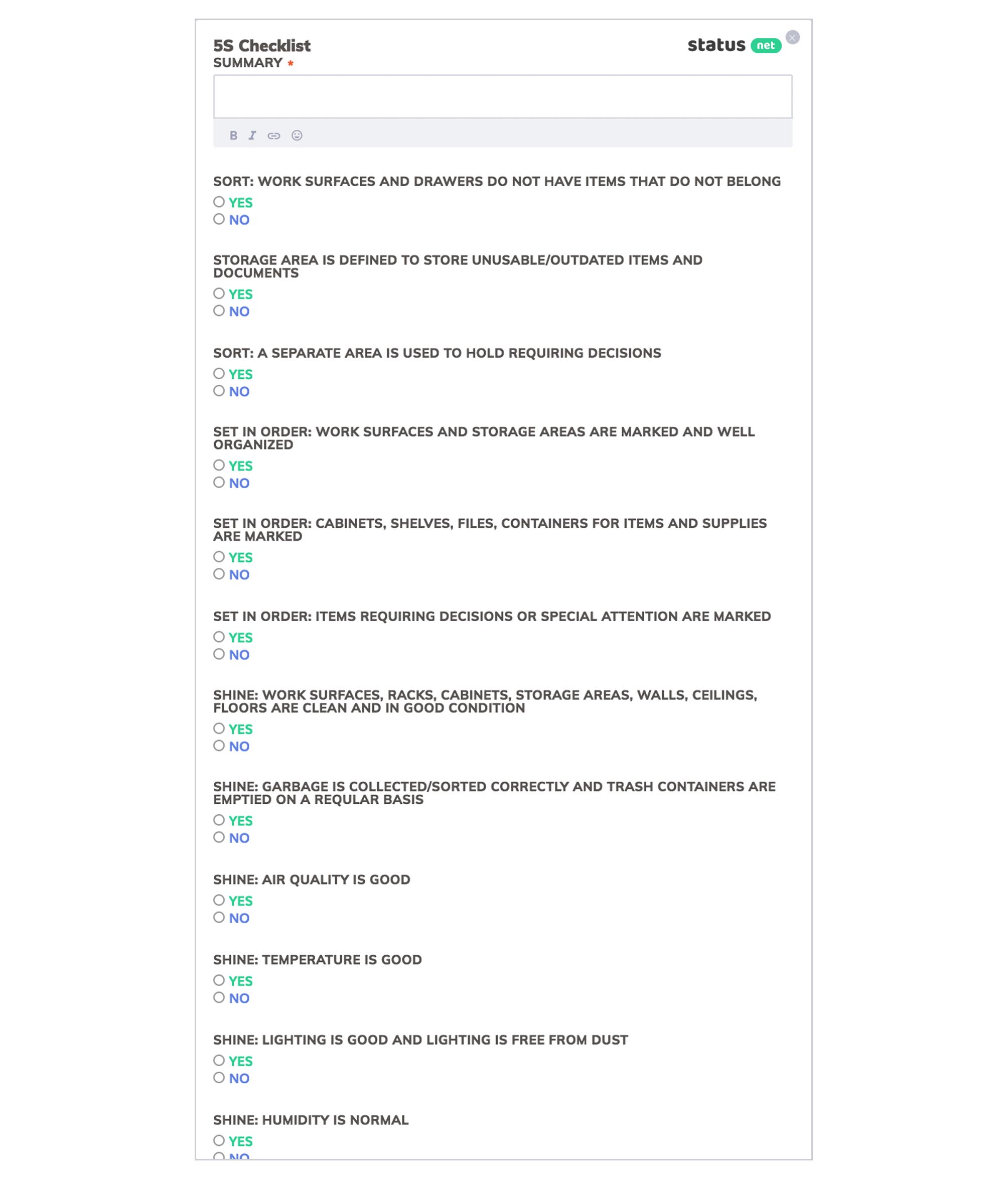

Its simple, common-sense application is highly effective and reliable as a stabilizing force in Lean strategies. Use the 6S Lean Safety Checklist to identify hazards or potential risks while performing tasks in the workplace. Implementation of this method "cleans up" and organizes the workplace basically in its existing configuration, and it is typically the first lean method which organizations.

5S-Lean method » Space or place for all and everything on its place « is the motto of 5S method. 5S in lean six- sigma is the approach that ensures smart workspace organization- known as ‘Good Housekeeping’. The five S’s in 5S are sort, straighten, shine, standardize and sustain.

Many companies will tell you that they implement lean 6S;. Apple iPhone 5s specs compared to Apple iPhone 6s. While adhering to the 5S principle of Sort, Set in order, Shine, Standardize, and Sustain, the 6S method adds the concept of Safety.

In order to be high- performing, the organizational workplace should be clean, which is guaranteed through 5S. An illustration of a bad office 5S initiative, as inspired by real events. Unfortunately, though, 5S is deeply ingrained in Lean culture, and would be extremely difficult to supplant with a new term.

In this case, more may not necessarily be better. 6S methodologies, is the necessary sixth S or safety element only required in the United States?. 6S Lean Safety Checklist.

This article isn’t likely to end the great debate over 6S vs. 6S Lean Poster 5S Sorting Event Recognition Board_SKU-9561 This 5S Sorting Event Recognition Board is great at promoting 5S improvements and team achievements for all to see. Now- a 7th S!.

6S being 5S plus the added step of safety. The new 6S system includes a single event in the continuous improvement process dedicated to safety.The net result:. Japan manufacturing plants seem to do well using the 5S Methodology as the sustain element does consider safety, but with America having so many workplace safety rules and organizations, that sixth S may be necessary prior to implement 5S in the U.S.

Deshalb sollten die Mitarbeiter mit ihren Vorschlägen. The Fenix 5s plus and 6s pro have impressive battery life that’ll see you through days on a single charge. Even though 5S comes with “built-in” safety benefits, that’s not the end of the story.

6S Lean focuses on what can be done to eliminate risks in work processes. While 5S proved its benefits over decades, if you can integrate safety precautions into the steps of lean management, you should definitely go for it.

5s Safety Lean 6s Safety Convergence Training

The Ultimate Guide To 5s Improving Workplace Efficiency Tulip

Poster Lean Workplace List For Sale At The5sstore Com

6s Audit 5s 1 Lean Workplace Checklist Reviqo

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

5s Organizing The Lean Workspace Engineering Com

Q Tbn 3aand9gctln6p9ybugnusih Kcfa5kya1ijloz8qducjl4t5i5ubxph19v Usqp Cau

What Is The Difference Between 5s And 6s Creative Safety Supply

5s Housekeeping Audit Model Leanfor6s Com

7s

6s For Safety Poster Lean And 5s Posters Also Available Custom Signs And Posters Too

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

5s Safety Lean 6s Safety Convergence Training

Implementing The 5s Methodology The First Steps Toward Workplace Efficiency

5s Or 6s 5s News Supplies Products And Reviews For Lean Professional

5s Lean Manufacturing And Six Sigma Definitions

Q Tbn 3aand9gcsoocfwr2kc9sd2is9pfesvhk S8lxmnub3ng Usqp Cau

Lean Chemicals Toolkit Chapter 5 Sustainability Us Epa

Do Your Processes Require Security Beyond 5s And 6s There S 7s Goleansixsigma Com

Lean 6s 5s Safety Global Wizdom

6s Poster 6s Lean Workplace Sp1248

Article Understanding The 5s S Of Kaizen 6 Sigma

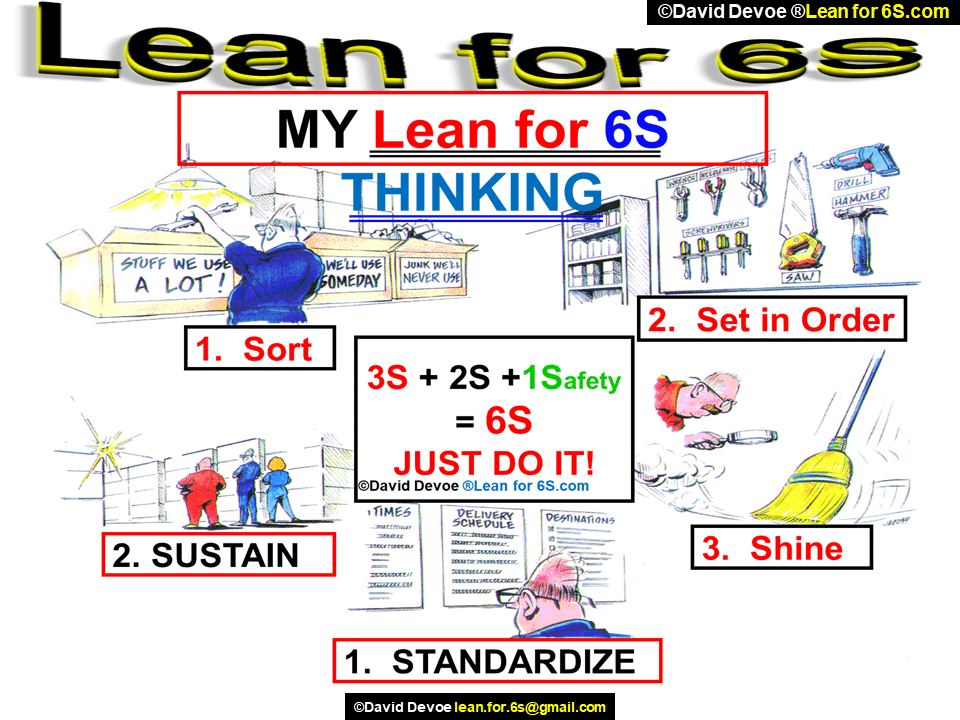

The 3s Of The 5s Leanfor6s Com

5s Vs 6s 5s News Supplies Products And Reviews For Lean Professional

What Is The Difference Between 5s And Kaizen Creative Safety Supply

What Is Lean 5s Brady

6s The 5s Store

6s System Infographic Lean Manufacturing Lean Six Sigma Change Management

Lean Manufacturing Principles From Concept To Implementation

5s Methodology 6s Health And Safety Poster Lean Sigma Lean Manufacturing

6s Meaning Clipart Lean Manufacturing Gemba 5s Clipart Text Product Line Transparent Clip Art

5s Vs 6s Utah Lean Six Sigma

Image Result For 5s S Vs 6s S Six Sigma Tools Lean Six Sigma Project Management Tools

Everything About 5s In Lean Manufacturing Lucidchart Blog

5s Standardize Creative Safety Supply

5s Is The Foundation Of Any Lean Program Infographic Creative Safety Supply

Six Sigma 6s Powerpoint Diagram Slidemodel

Poster Lean Workplace Circle 6s At The5sstore Com

6s S For Safety Poster We Provide Lean 5s And 6s Posters And Make Custom Signs Too Safety Posters Health And Safety Poster Safety Slogans

Implementing The 5s Methodology The First Steps Toward Workplace Efficiency

Remember 6s For A Lean Workplace Poster Safetycal Inc

5s Lean Objectives Standards And More Safetyposter Safety Poster

010 What Lean 5s Methodology Is All About Lean Smarts

5s And 6s Lean Manufacturing Our Business Is Protecting Yours

Custom 5s Banners And Posters Lean Manufacturing Healthcare Quality Lean Sigma

Lean 6s 5s Safety

5s What Are The Five S S Of Lean Asq

What Is 6s Lean 5s Safety

6s Tutorial For Lean Approach

5s Overview Leanfor6s Com

The 5s System Lean Manufacturing Methodology

5s Or 6s What S The Safe Choice

5s One Of Lean Six Sigma S Finest Tools

High Quality 5s Poster

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

5s Or 6s Lean Management Technique Possible Uses In Project Management Ipma International Project Management Association

Keys To Sustaining 5s Workplace Lean Six Sigma Process Improvement

Free 5s Lean Manufacturing Software And Best Practices Status Net

6s Workplace Banner 5s Lean Workplace Chart 28 X 8 Ceilblue

An Introduction To Lean Six Sigma

5s Archives Lean Smarts

Moving From 5s To 6s Naem

Do Your Processes Require Security Beyond 5s And 6s There S 7s Goleansixsigma Com

5s Is The Foundation Of Any Lean Program Infographic Creative Safety Supply

5 Reasons 5s Is A Good Place To Start Your Lean Journey Lean Six Sigma Lean Manufacturing Kaizen

5s Sort Set Shine Standardize Sustain

A Look At 5s Vs 6s Methodology Do American Workers Need 6s Brighthub Project Management

5s Vs 6s Utah Lean Six Sigma

Everything About 5s In Lean Manufacturing Lucidchart Blog

Safety Banners 6s Lean Workplace The 6 S S For Sale At 5s Store

Lean 6s 5s Safety

Home Lean Six Sigma Toolbox

Implementing 6s Lean Methodology In Our Production Plant Estanc

Lean 6s Management System Lean Refers To Maintaining A Zero Waste By Liveroom Medium

5s 6s Rapid Improvement Events American Lean Consulting

Improve Workplace Safety With 5s Realsafety Org

5s Safety Lean 6s Safety Convergence Training

Iphone 6s Vs Iphone 5s Comparison Review Macworld Uk

Using The Steps For 5s Red ging Enna Com

High Quality 6s Poster

Amazon Com 5s To Success Lean Poster Bilingual Spanish And English 22 X 28 Made In The Usa Office Products

6s Tutorial For Lean Approach

Muda Corporation The Pitfalls Of 5s

The 5s System Lean Manufacturing Methodology

5s Lean Manufacturing And Six Sigma Definitions

6s Banner 6s Workplace Mbr9

5s Lean Manufacturing And Six Sigma Definitions

Q Tbn 3aand9gcr Ysm Pemthhdfzzglw 5bupwwiesimniozsyejstcmev7ac 3 Usqp Cau

Continous Reduction Of Cost Using Lean Sigma Tools 5smanagement Com

Amazon Com 6s Lean Benefits Poster 11 X 14 Made In The Usa Office Products

Safety Banners 6s Lean Workplace The 6 S S For Sale At 5s Store

Iphone 6s Vs Iphone 5s Comparison Review Macworld Uk

6s Area Sign 5s Supplies Llc

What Is 6s Lean 5s Safety

5s And Safety 6s The Way Of Life Youtube

5s Office To 5s Manufacturing Results Lean Production Youtube

What Is Lean 5s Brady

6s Lean Workplace 1 Sort 2 Set In Order 3 Shine 4 Standarize 5 Sustain 6 Safety 24 X 18 Pst5 Jendco Safety Supply