5s System

5s Sort Simplify Shine Standardize Sustain Slip Free Systems Commercial Industrial Residential Floor Coatings

The 5s System Lean Manufacturing Methodology

5s System Success Stories Workforce Solutions Group St Louis Community College

Lean 5s Workplace Organization And Visual Management For Construction Companies Sysnovate Solutions

The 5s System Lean Manufacturing Methodology

5s System Implementation

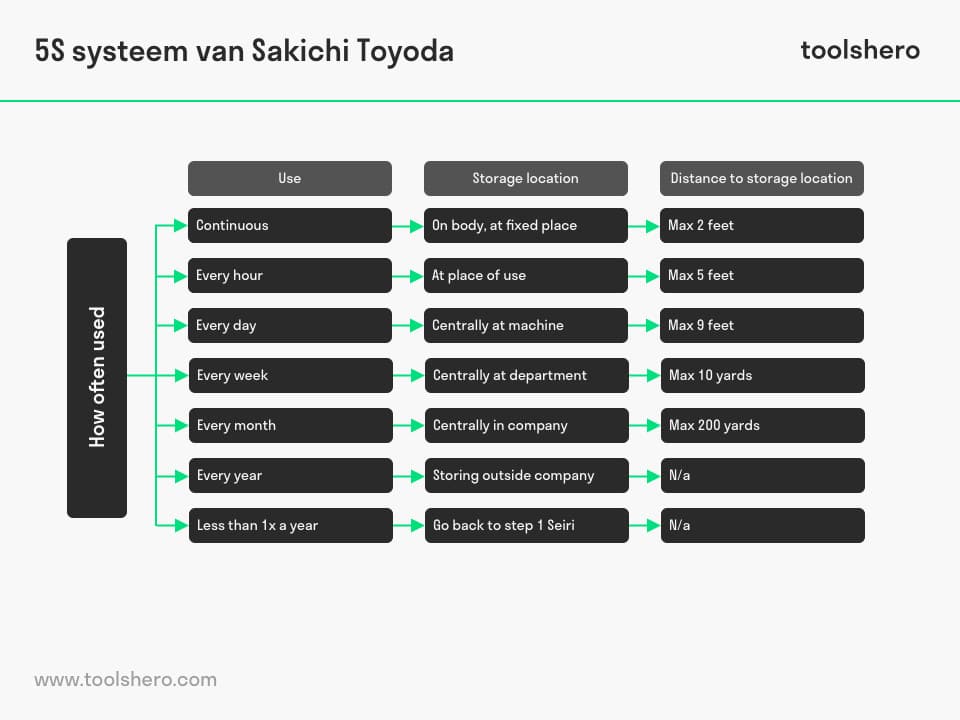

In the 1970s it was Sakichi Toyoda who developed the 5S System within the broader Total Production System (TPS).

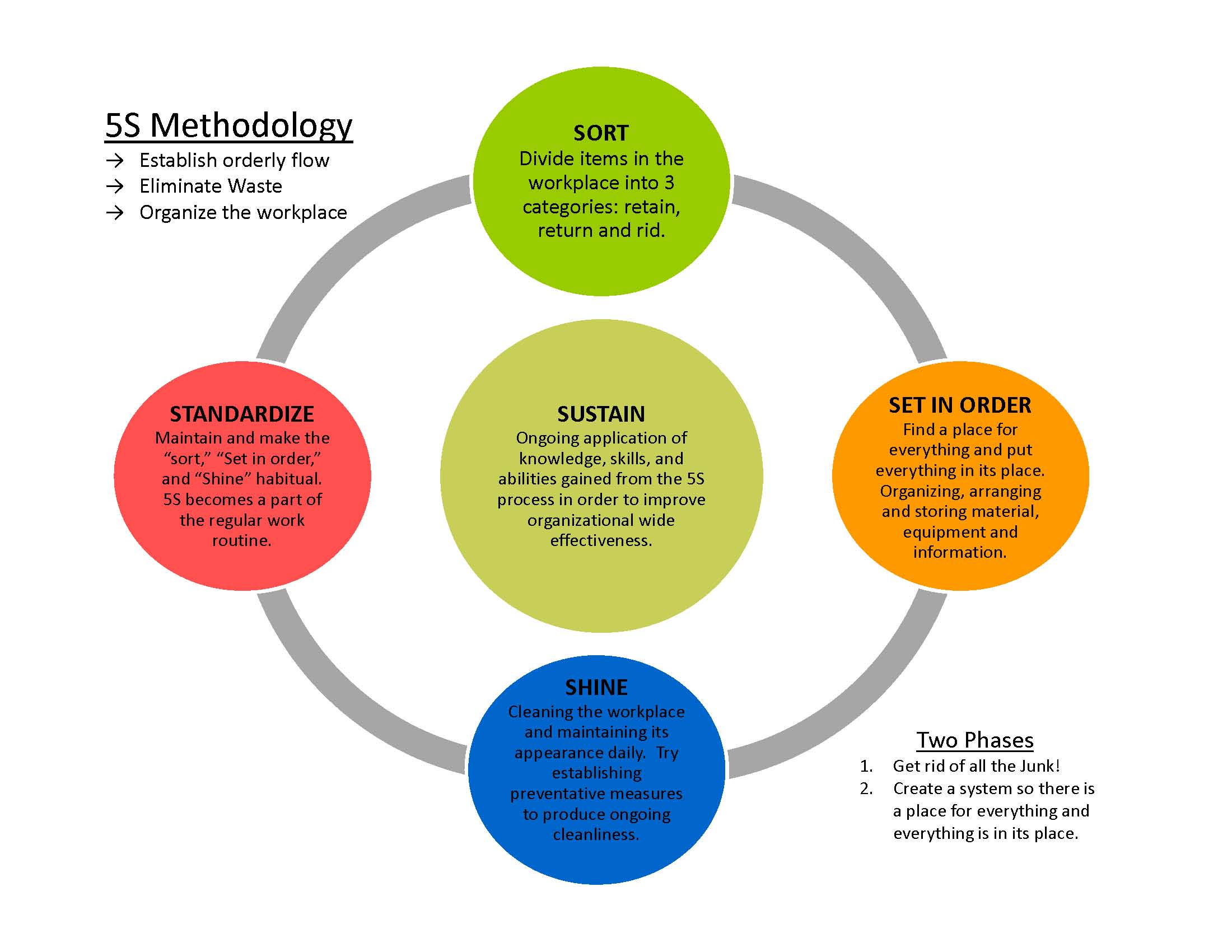

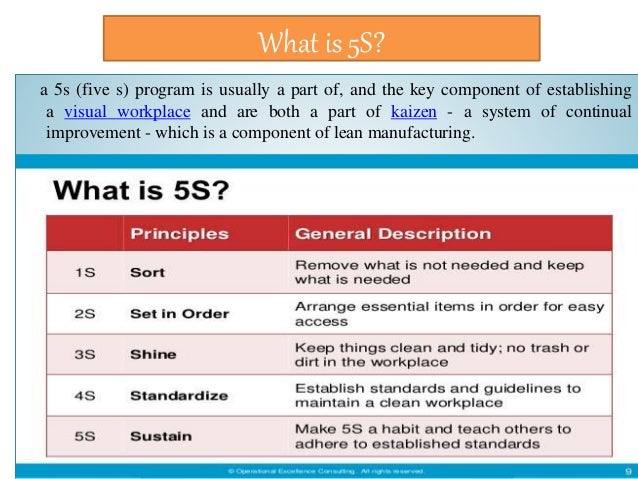

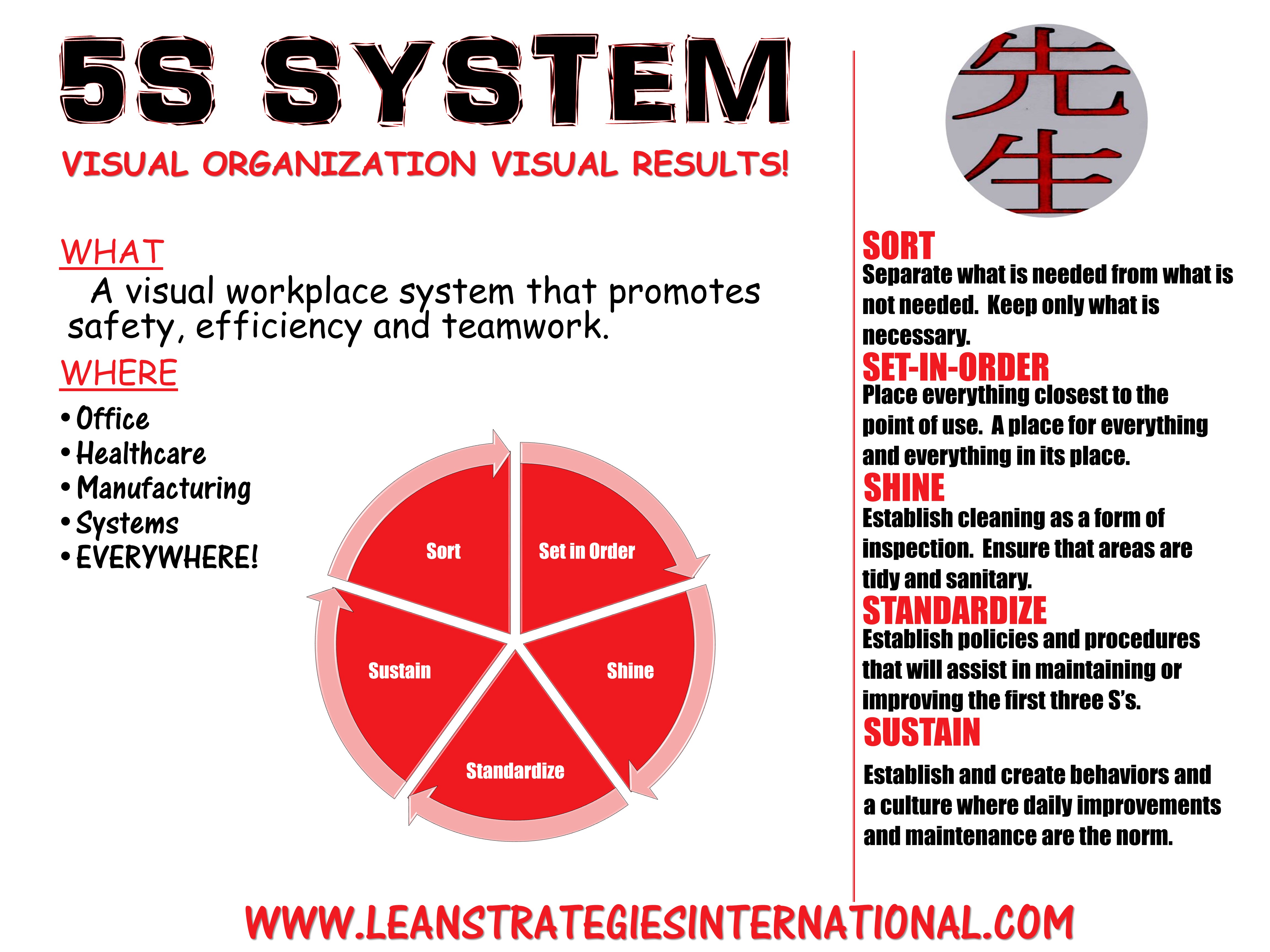

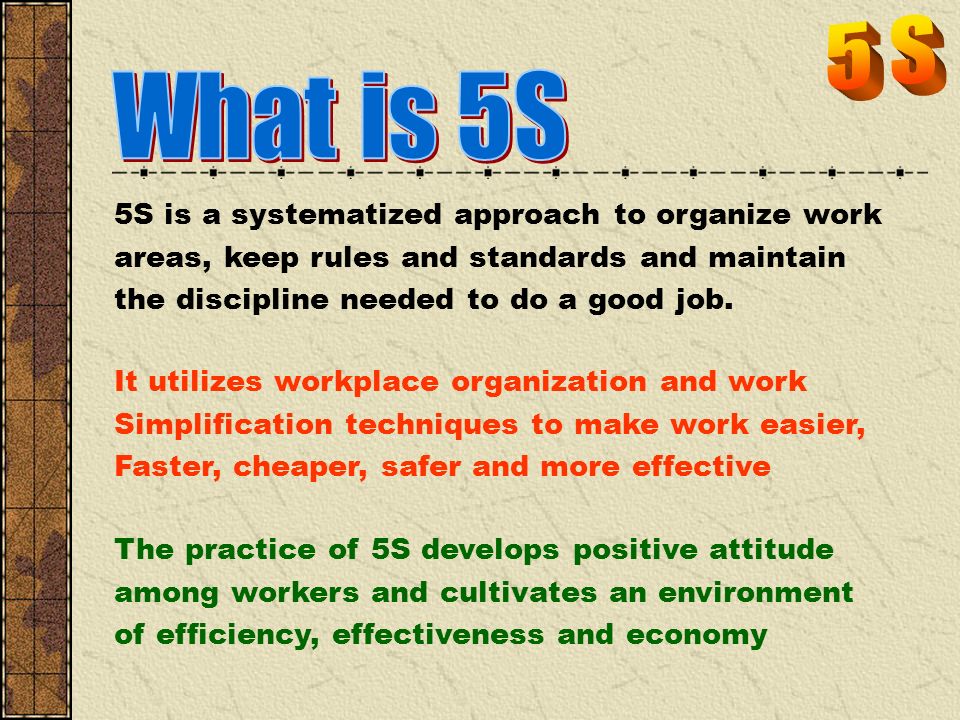

5s system. As many organizations attempt to become the best in their service, a good management system is required and therefore, the implementation of 5S is highly recommended. A 5 S program focuses on having visual order, organisation, cleanliness and standardisation. 5S is a system to reduce waste and optimize productivity through maintaining an orderly workplace and using visual cues to achieve more consistent operational results.1 5S programs usually are implemented by small teams working together to get materials closer to operations – right at workers’ fingertips – and organized and labeled to.

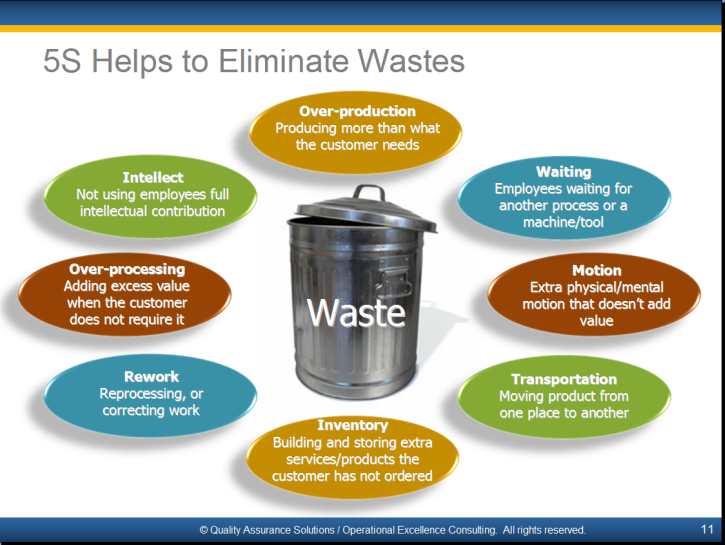

And, it accomplishes this by removing what’s called the Eight Wastes. Where problems in the workplace become obvious and visual. It is a proven way to improve efficiency and eliminate waste in almost any work environment.

Everyone thinks they know what housekeeping is, but it's one of the easiest things to overlook, especially when. There is a danger in any improvement activity that once the focus is removed and another top priority arises, things go back to the way they were before (the informal system). 5S is known as the 5 pillars.

It’s a great idea to limit the number of colors you decided to use with your color-coded system. The five steps/pillars of 5S are:. Sort (organization) Set in order (orderliness).

It was first popularized by Taiichi Ohno, who designed the Toyota Production System and Shigeo Shingo, who also put forward the concept of poka-yoke. 5S is sometimes called the five pillars because just like the physical pillars that hold up a structure, 5S has five elements that support the effectiveness of the system. It is within the reach of all type and size of industry or organisation.

The iPhone 5S is powered by the Apple system-on-chip, the first 64-bit processor ever used on a smartphone. Understand essential components of effective 5S labeling, and learn how to choose the right label supplies for your needs. 5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity.

The 5S system has been developed and evaluated by companies around the world. The Steps of 5S Step 1:. The Andon is placed outside the First Aid Room, to notify anyone walking by.

1S - Seiry - nechat na pracovišti jen nutné věci, 2S - Seiton – vyjasnit si posloupnost pracovních kroků, 3S - Seiso - vracet nástroje na své místo, 4S - Seiketsu – znát předchozí 3S. • 5S is a philosophy and a way of organizing and managing the workspace and work flow with the intent to improve efficiency by eliminating waste, improving flow and reducing process unreasonableness. This is the beauty of the 5S system.

Seiri, seiton, seiso, seiketsu, and shitsuke. This interactive online course will teach you how to focus the 5S System on safety. Understanding and following the 5S System for safety will give you the foundation to improve safety and productivity in your workforce.

The list describes how to organize a work space for efficiency and effectiveness by identifying and storing the items used, maintaining the area and items, and sustaining the new order. It uses visual signs to ensure that certain conditions, instructions, and actions are. A variety of names have been used in English:.

The 5S system is a step-by-step way to transform a workplace from one of disorder and clutter to an organized and productive one. 5S is an effective tool for identifying and eliminating wasteful practices from your workplace. The 5S system is an important part of the Toyota Production System, which provides us with a way to organize and maintain a workplace in order to achieve maximum efficiency and effectiveness.

Six best practices for using a color-code system effectively:. It focuses on making an area more efficient by removing unnecessary clutter and laying out items in an ergonomic and safe manner. 5s kya hota hai, What is 5s?.

The 5S concept is easy for everyone to understand because:. 5S is a system and way of organizing and managing workspaces to improve efficiency by eliminating waste, improving flow and reducing the number of processes where possible. Based on the original SMH5 architecture, the new Sena 5S remains a small form factor, easy to handle, easy to mount, and easy to use system, but it now boasts Bluetooth 5.0 features and capabilities, HD audio and HD intercom, a fast-charging easy-connecting USB-C interface, and a host of other features, including a small LCD screen.

We recommend starting with:. It's designed to help build a quality work environment, both physically and mentally. It does not require the understanding of difficult terminologies.

The performance of 5S in a workplace could be evaluated using a 5S Checklist, which is a tool that will help ensuring that 5S standards and workplace organization are being met. Get an in-depth breakdown of how to implement each step of a 5S system, which helps improve efficiency and safety facility-wide. The 5S philosophy applies in any work area suited for visual control and lean production.

Once you understand the principles, you can utilize them in countless ways. The 5S System, or the Five Lean Principles, started as a manufacturing methodology to improve management. Fantastic example of the first 3 phases of 5S.

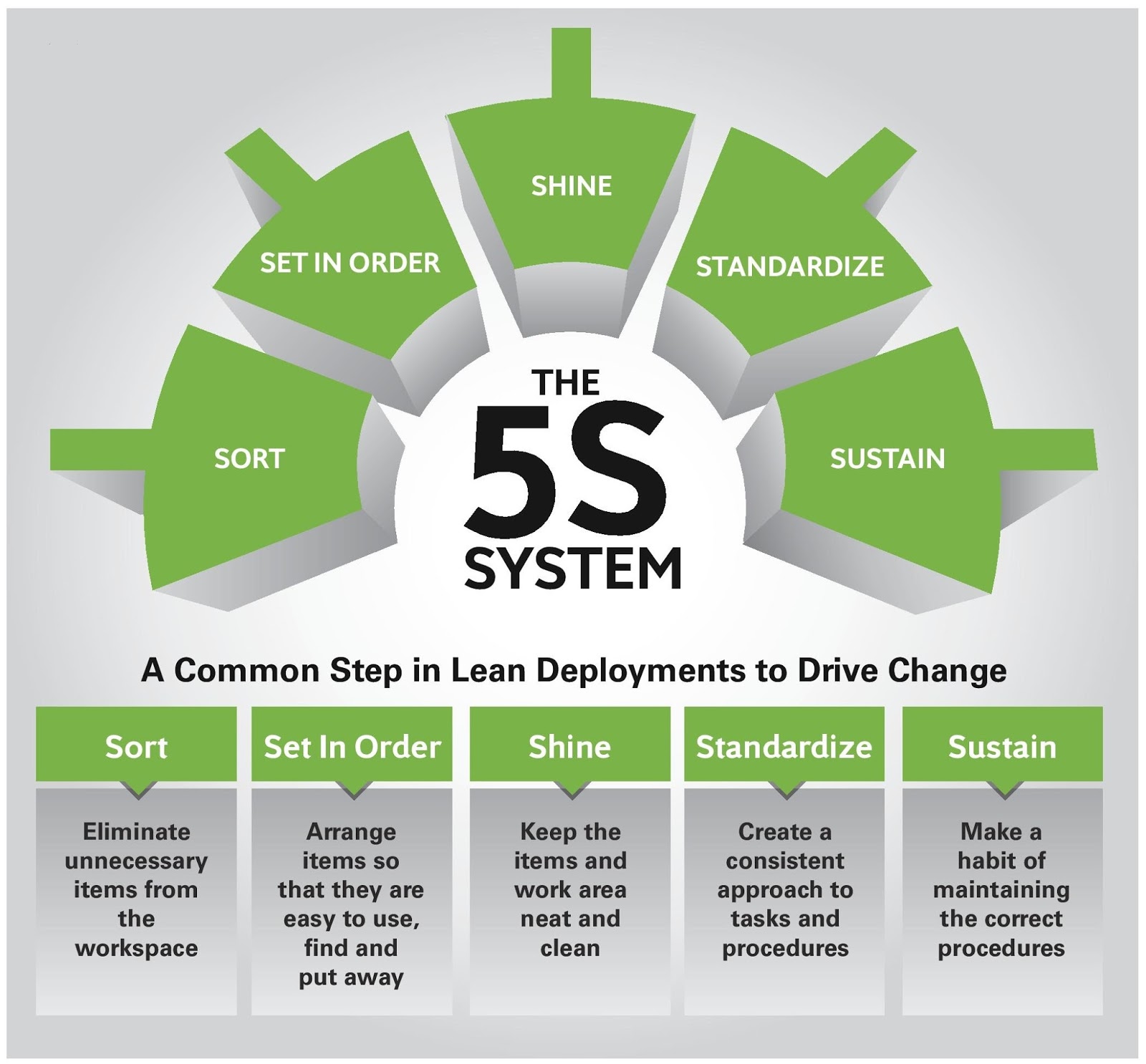

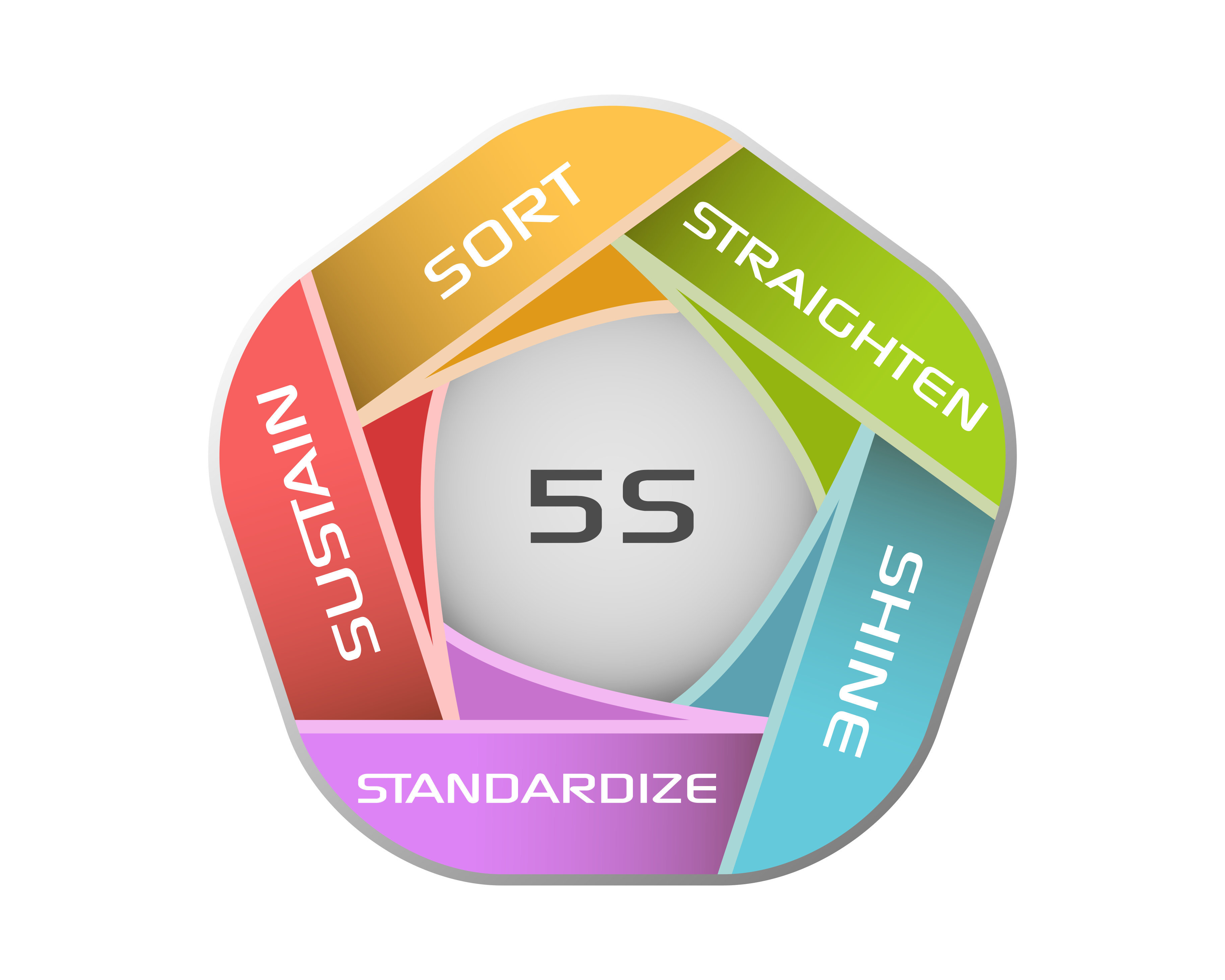

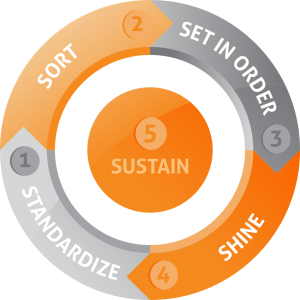

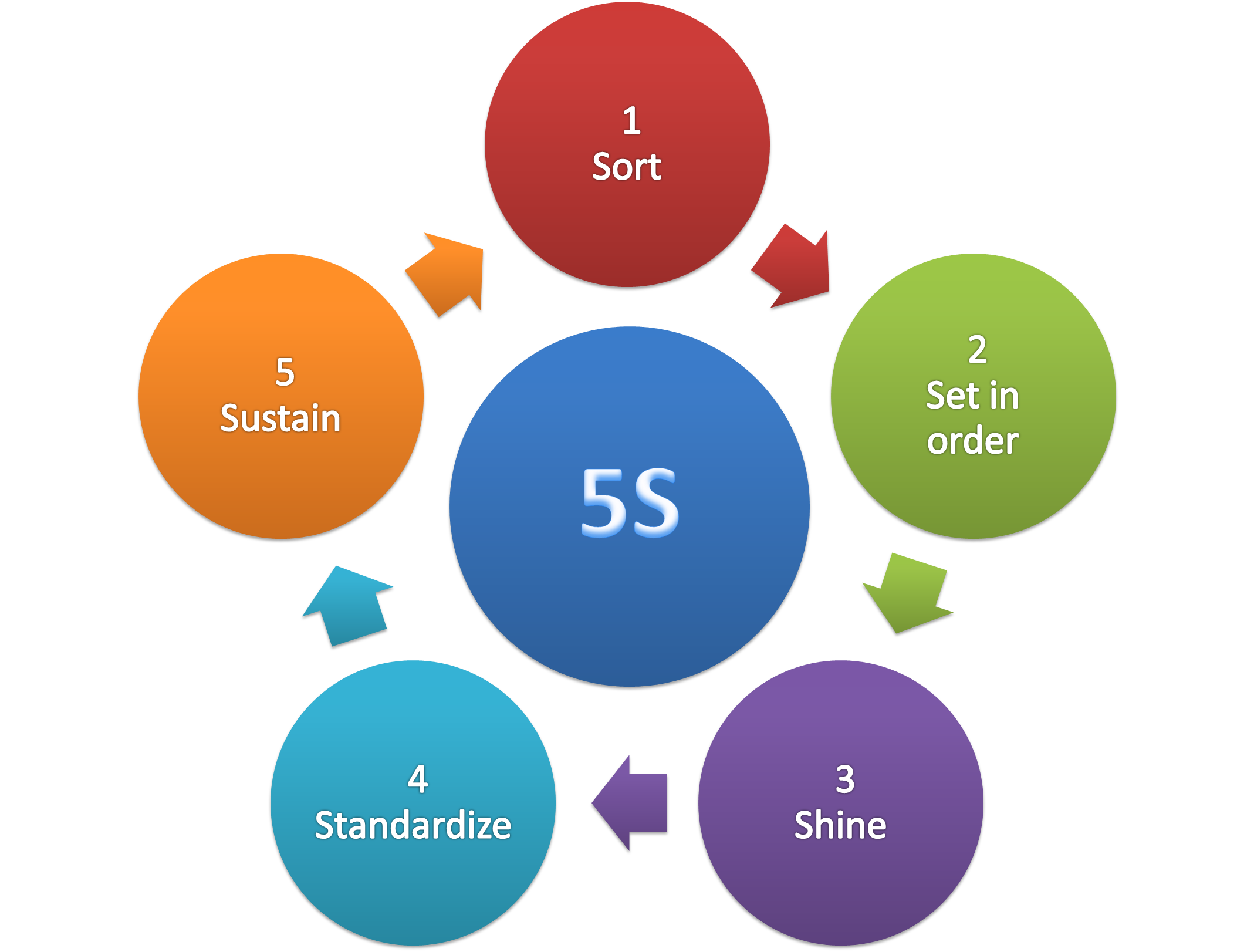

These have been translated as "Sort", "Set In order", "Shine", "Standardize" and "Sustain". The 5S Method is a standardized process that when properly implemented creates and maintains an organized, safe, clean and efficient workplace. 5S, sometimes referred to as 5s or Five S, refers to five Japanese terms used to describe the steps of the 5S system of visual management.

5S principles reduce waste and increase efficiency. Each term starts with an S. And just like the pillars of a building, if one was to weaken or fail, the entire structure would fall.

How can you implement 5S into your business?. 5S + 1 and Visual Management Systems Are Everywhere We Look What Is 5S + 1?. 5S Education Interested in 5S?.

Now work groups can come up with their own. It is simple, driven by logic and natural to human behaviour. Advantages of 5sadvantages of 5s • visusu g s sal management system • visual control to see the abnormalities • simple signals that provide an understanding of the condition (normal/ abnormal) • a look at the process reveals its direction (right/wrong) 15 (/).

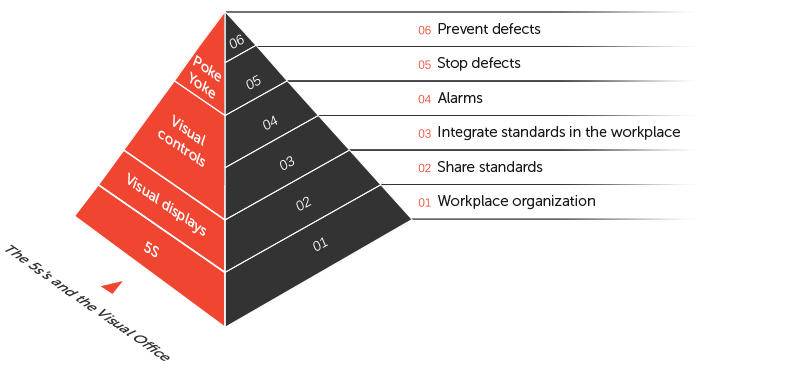

5S is a systematic way to improve and maintain the level of housekeeping in the workspace. 5S is the foundation of all improvements and is the key component of establishing a Visual Workplace. Naming trivialities aside, though, the purpose of 5S is straightforward:.

The goal of the Sort step is to eliminate clutter and clear up space by removing things that don’t belong. Learning as much as you can about this system will help to ensure your workplace gets all the benefits of this system without any trouble. Once the extra clutter is gone, it's easier to see what's what.

The 5S methodology has been widely spread, and many companies and organizations are implementing it worldwide. Popular solid colors used for color-coding are black. With 5S, you are implementing an entirely new system!.

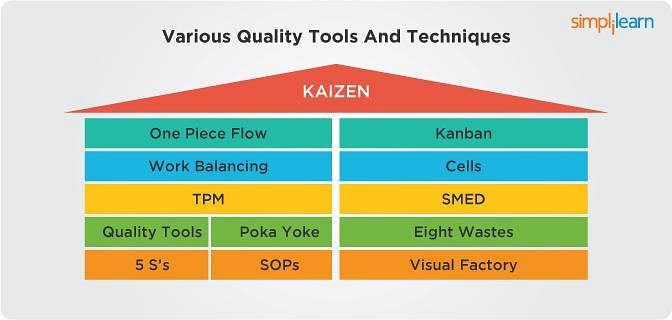

It is for improvement of. The 5S System is a technique used in Lean Manufacturing to achieve a safe, neat, clean arrangement of the workplace. Both are a part of Kaizen — a system of continual improvement which is a component of lean manufacturing.

The history of 5S System seems to go back as far as the 16th Century and Venice shipbuilders. What is the 5S System or the Five Lean Principles?. The Sena 5S is the successor to the Sena SMH5 and is the ideal choice for the next-generation of riders.

#5sMethodology #5sLeanmanufacturing #shakehandwithlife Download eBooks in PDF 5S Methodology:. Demonstrate your appreciation to your team members with our wide selection of reward and recognition products. Created and perfected by Toyota, 5S incorporates a system of visual cues that help reduce waste and achieve more consistent operational results by maintaining an orderly workplace.

5S - Shitsuke – udržet pořádek na pracovišti. “Systematic Organization,” “Straightening Out,” and. But it isn’t enough to just say ‘oh, I’ll simply clean up after myself’.

Standardization Standardization can be the thought of as the means by which we maintain the first three 5S concepts. 5S System Improves Workplace Organization, Productivity Share In a manufacturing production environment, having an organized and orderly workplace leads to better flow and greater efficiency and often allows workers to produce more at a sustained rate. In order to be high- performing, the organizational workplace should be clean, which is guaranteed through 5S.

If you've got a handle on 5S and would like to learn more about other Lean Manufacturing / 5S topics, please check out the links below. 5S is a part of Kaizen and Kaizen is a part of 5S. In an effort to streamline the assembly process, workers used quality process production to build ships in hours instead of days or weeks.

5s kya hota hai 5s full form in Hindi, 5 यस क्या है 5s किसे कहते है, 5s in Hindi, what is 5s in Hindi, 5s meaning in hindi, 5s system in Hindi, 5 यस 5s किसे कहते है जानकारी हिन्दी मे। 5एस क्या होता है. The 5S methodology is easy for everyone to start using. Let’s go through each of the 5 S’s one by one and look at how you can implement them and make 5S work as a system for you.

The 5S methodology was born at Toyota in the 60s under an industrial environment to achieve better organized, tidier, and cleaner workplaces to increase productivity and to obtain a better working environment. 5S+1 is a 6-step process. In simple terms, the five S methodology helps a workplace remove items that are no longer needed (sort), organize the items to optimize efficiency and flow (straighten), clean the area in order to more easily identify problems (shine), implement color coding and labels to stay consistent with other areas (standardize) and develop behaviors that keep the workplace organized over the long term (sustain).

A 5S implementation helps to define the first rules to eliminate waste and maintain an efficient, safe, and clean work environment. How to Implement the 5S System. Everything has a place and is in its place.

5s - Housekeeping technique In order to achieve high levels of quality, safety and productivity (5s manufacturing), system help to reduce cost at workplace. This website is a great resource for everything 5S, from products to education on 5S and other Lean Manufacturing topics. 5S helps you to improve worker safety, productivity, quality, and efficiency.

The 5S System is a set of universal principles and activities that sustain high performance in companies in any industry. Once the first three. In English, the five S's are translated as Sort, Set in Order, Shine, Standardize, and Sustain.

Visit Sena today to learn more. The 5S system is often a starting place for implementing lean operations 5S in lean six- sigma is the approach that ensures smart workspace organization- known as ‘Good Housekeeping’. If we translate them into English, we get:.

While the first and. 5S systems are common in manufacturing, warehouses, offices and hospitals but 5S principles can be applied to any workplace. The device's operating system and pre-loaded software were optimized to run in 64-bit mode, promising increased performance, although third-party app developers would need to optimize their apps to take advantage of these enhanced.

5S team t-shirts help instill a sense of ownership in your team while also serving as visual reminders of the foundational 5S concepts. With too many colors employees tend to become confused and fail to follow the standard. In Japanese, the five S's are Seiri, Seiton, Seiso, Seiketsu, and Shitsuke.

Seiri (整理), seiton (整頓), seisō (清掃), seiketsu (清潔), and shitsuke (躾). So, using Maryanne’s guidelines, I decided to 5S my life in two general categories – professional and personal!. BENEFITS OF 5S IMPLEMENTATION Today, many organisations have implemented the 5S system.

5S stands for five Japanese words:. 1 Sort 2 Set in Order 3 Shine. It enables the observer to better address compliance gaps and provides an opportunity for continuous improvement.

What exactly are the 5S’s in the 5S System and what do they mean?. They’re meant to be followed chronologically and cyclically, as each stage of the practice enables the next and the process as a whole is designed to continually optimize the use of the workspace. 5S is a system to reduce waste and optimize productivity through maintaining an orderly workplace and using visual cues to achieve more consistent operational results.

5S zpřehledňuje a zjednodušuje pracoviště. 5S is a workplace organization method that uses a list of five Japanese words:. This is because the cornerstone of efficiency is to have a clean and safe working environment.

Red – if there is an emergency in process in the first aid room and should not enter, Yellow – if supplies are getting low, the person who restocks the first aid room walks by it everyday going to their office. What Are the 5 S's?. 1) Keep your 5S color-coded system simple.

The 5s System Framework In Management Benefits And Process

Hse Insider The 5s System

5 S Lean System Online Tools Web Templates

National Board For Quality Promotion The 5s System Is A Lean Manufacturing Tool That Improves Workplaceefficiency And Eliminates Waste It Has 5 Pillars Qualitycouncil Qci Nabet Director Nabh Nabl Qci Nabcb Qci Zed Qci Qcielearning

What Is 5s Quora

How The 5s System Can Help Your Business Klipspringer Klipspringer

5s Events And Continuous Improvement Beckman Coulter

What Is 5s The Secret To Japanese Success Housekeeping Technique

Document Management A 5s Opportunity Continuous Improvement Blog

We Employ The 5s System Of Workplace Organisation At Westin Drives Westin Drives

The 5s System Is A Lean Manufacturing Suvarna Consultants Facebook

5 S Lean System Online Tools Web Templates

How To Implement The 5s Methodology Advance Tapes

Benefits Of 5s Unique To The Food Industry Amerisan

Operation Team Introduces The 5s Lean Manufacturing System West Pak Avocado Inc

Everything About 5s In Lean Manufacturing Lucidchart Blog

5s Management System

Ignition Coil Alternator Starter Manufacturer Ribo Auto Parts

5s Or The First Steps Toward Workplace Efficiency Skilltec

What Is 6s Lean 5s Safety

What Is 5s Methodology 5s Quality System 5s Workplace Methodology 5s Lean Manufacturing Youtube

5s System Promoting Workplace Quality And Safety Mahmoud Saad

5s System Process Infographic Template

The 5s S And The Visual Office Productivity Keeping Enterprise In Motion

5s Five Ss 5s Program Sort Straighten Shine Standardize Sustain Lean Manufacturing Lean Production And Toyota Production System Tps Key Elements

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

Occupational Health And Safety The Advantages Of Implementing A 5s System

6 A6f6mwm5fokm

Lean 6s 5s Safety

Implementing The 5s Methodology The First Steps Toward Workplace Efficiency

5s System For Spare Parts Inventory And Fleet Maintenance Fleetio

Glossary Lean Strategies International

5s Lean Manufacturing And Six Sigma Definitions

What Is 5s Housekeeping Lean Manufacturing Improve Productivity Kaizen

Lean 5s And Plastic Injection Moulding Tex Plastics

5s System Implementation

5s System

The Conceptual Model Of Implementation Of 5s System Download Scientific Diagram

Bring 5s And Lean Management To Your Own Desktop

5s System An Introduction Dvd Productivity Press Tel A Train Amazon Com Books

The 5s System Are Sort Set In Order Shine Standardize And Sustain Training Programs Lean Enterprise System

Kalasam Case Studies 5s Implementation

The 5s System 5s For Safety New Eyes For The Shop Floor Youtube

5s System

5s Assessment With Scorecard Process Improvement Templates Assessment

5s System A Powerful Quality Management Philosophy Toolshero

The 5s System Infographic System Workplace

5s For Manufacturing What Is 5s System And How To Implement In Garments Industry Tools For Manufacturing

Lean 5s Six Sigma Safety Science

5s System Summary Process Infographic Template

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

The Impact Of The 5s System On The Healthcare Workplace Trindent Consulting

The 5s System Graphic Products

5s System Improves Workplace Organization Productivity Cbia

What Is 5s And Why Do We Want To Do It 5s System Tech Patidar

Standardize The 5s System Geoteck Services Inc

In 5s There Are Actually 6 Steps Check Out This Overview Of The 5s System Lean Manufacturing Lean Six Sigma Lean Sigma

5s System Quality Apparel With 5s System Quality Testing Apparel And Textiles Fibre2fashion

3

5s System Fabufacture Uk 5s System Sustaining 5s Sort Fabufacture Uk

Using A 5s System In A Forklift Shop

5s System Kit Workplace Organization And Standardization Productivity Press Tel A Train Amazon Com Books

Q Tbn 3aand9gcs4td16wgm4mhec2cuvoziy5xbmnibxqqdlroip23vh5gp8ceo6 Usqp Cau

5s Questions And Answers Creative Safety Supply

What Is The 5s System Definitions Core Concepts Principles Graphic Products

Understanding The 5s System Tqmi

Canon Production Systen Cps Five Ss 5ss At Canon Kaizen And Lean Production

What Is 5s Lean Learning Center

Q Tbn 3aand9gcsoocfwr2kc9sd2is9pfesvhk S8lxmnub3ng Usqp Cau

5s System In Our Shop Aerotex

5s Lean For Cleanrooms Angstrom Supply

What Is 5s System Know All About It

Q Tbn 3aand9gcrvpfxh6mhunxan6k69bfbx4wwjubliifvycuceyxygtgdzdggz Usqp Cau

5s System Guide Benefits Implementation And Training Tools Graphic Products

Quality System 5 S Ppt Video Online Download

Q Tbn 3aand9gcqyukp8ykmaapvkrgve86ktagccu6hil3zyhw Usqp Cau

5s System Creative Safety Supply

The 5 S System

The 5s System Lean Manufacturing Methodology

5s Implementation Consulting Services 5s Training Lean Five S System Ims

What Is 5s System Know All About It

5s Workplace Organization Cleaner With Dean

Toyota 5 S System

5s Cleaning System 100 System Of Cleanliness System100

The 5s System An Introduction To 5s Training Video

Free Online 5s Certification Training Course Alison

5s Methodology Wikipedia

Teach This 5s Process With This 5s Ppt

The 5s System An Essential Lean Tool Part 4 Of Big Fat Lean

5s System A Powerful Quality Management Philosophy Toolshero

Overview Of The 5s System Youtube

Q Tbn 3aand9gcrswe5ngqqk7zdmrgtcuous Oo2xjplshwkur4nth Y6uxdk2dp Usqp Cau

Learn The Basic 5 Steps Of The 5s System For More Information Visit Our Website At Www Leanstrategiesinte Visual Management Lean Six Sigma Change Management

The 5s System Workplace Organization Standardization Mrc Mrc

5s System Download Scientific Diagram

The 5s System Geoteck Services Inc Cnc Services

5s System In Garment Industry Cross Functional Team Reward And Recognition Industrial