5s Principles

Understanding The 5s Principles

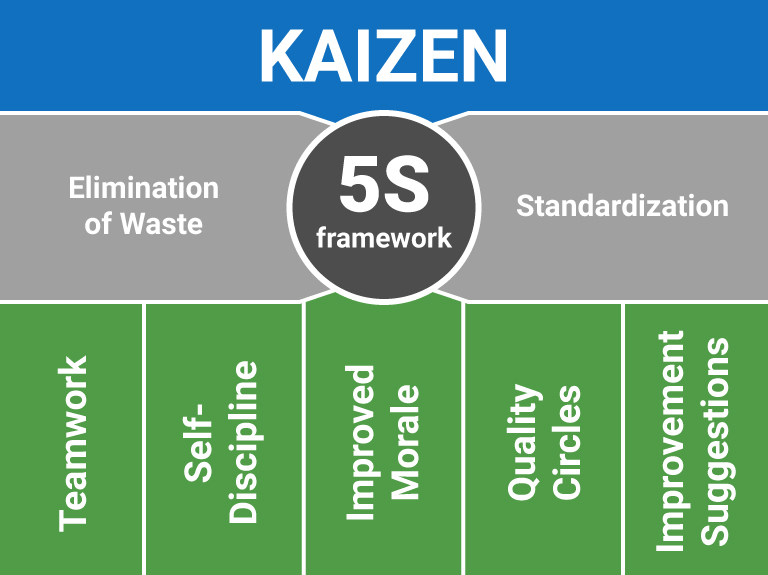

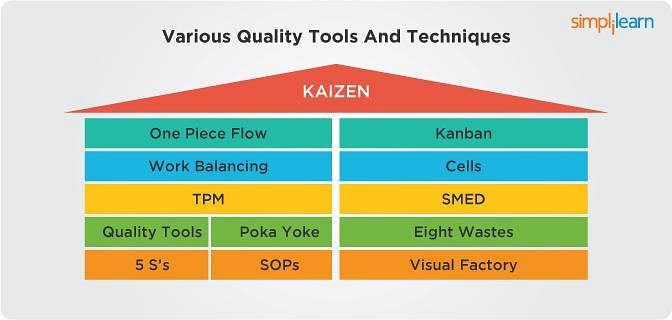

What Is Kaizen Continuous Improvement

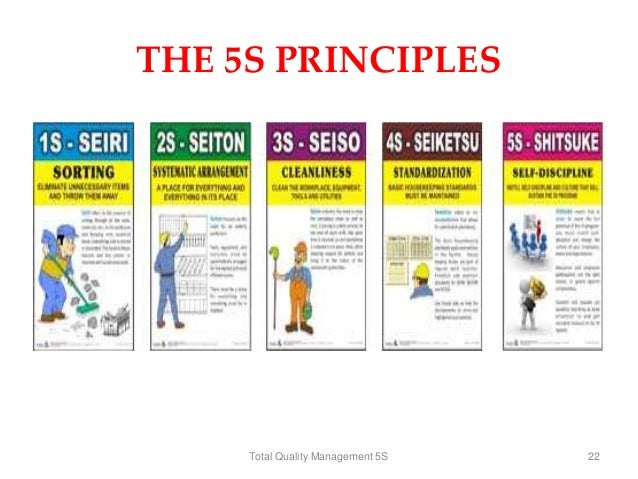

The 5s Principles

5s Implementation In The Office

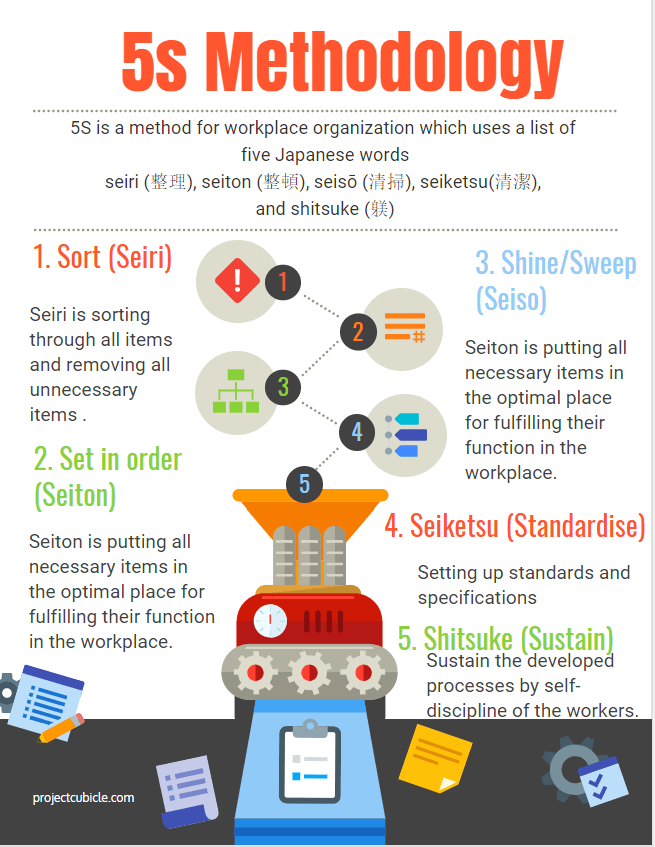

5s Methodology Principles In Project Management Projectcubicle

5s Lean Manufacturing Principles Ppt Powerpoint Presentation Slides Files Cpb Powerpoint Templates Download Ppt Background Template Graphics Presentation

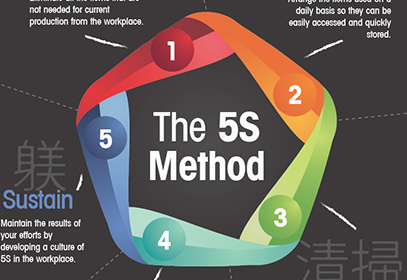

The 5S method is a way to organize your workplace to increase productivity while reducing stress and frustration.

5s principles. 5S events are an excellent way to ensure that workspaces remain organized and clutter-free. To conduct a cleanup campaign. Once the first three.

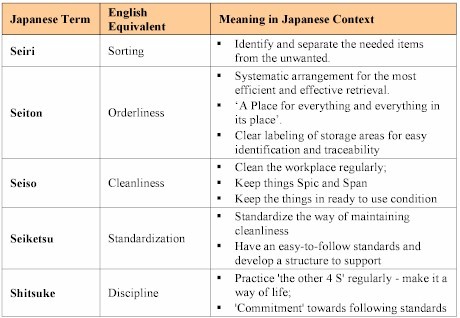

Another important facet of 5S is understanding where 5S originated, why it is so popular…. To separate needed tools, parts, and instructions from unneeded materials and to remove the unneeded ones. The Steps of 5S.

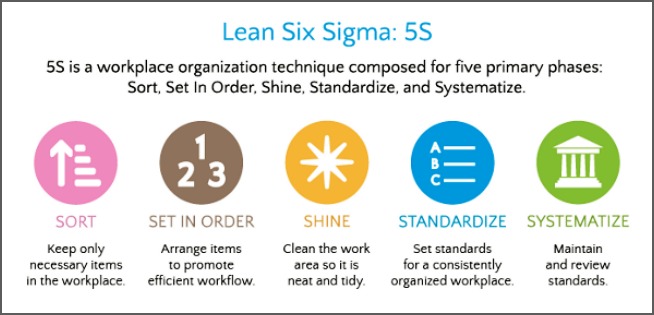

One of the main purposes of 5S is to prepare the work environment to hold visual information. From that perspective, 5S is a method, while creating a visual workplace is the goal. 5S is a workplace organization method that uses a list of five Japanese words:.

The pillars of 5S are simple to learn and important to implement:. They used it as part of their production system in the mid- th Century. 5S Method is a methodology or a set of principles for creating and maintaining an organized, cleaned and high-performance workplace.It is a basis and natural part of the lean approaches.

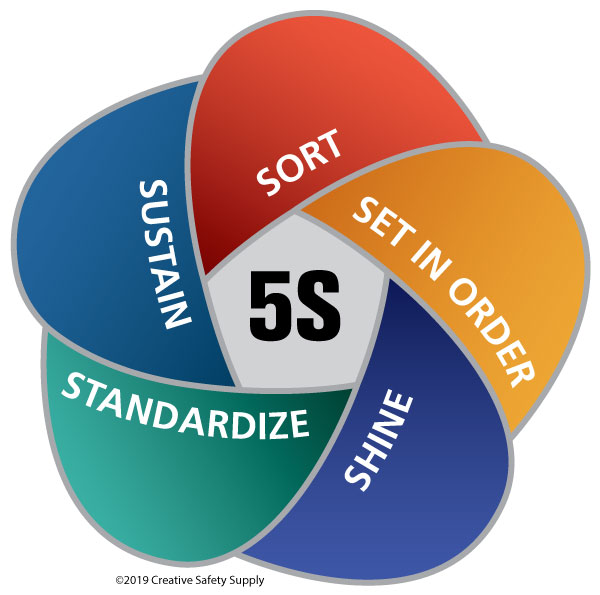

As one of the most versatile Lean techniques, 5S can be used in almost any work environment, whether it is a busy white collar office, the auto shop or the factory floor. These have been translated as "Sort", "Set In order", "Shine", "Standardize" and "Sustain". Applying the 5S Principles to any team can dramatically increase safety in pits everywhere.

In addition, productivity increases and quality improves when unnecessary items are eliminated. Show your workplace organization and 5S program is in place with bright, colorful words and graphics. “A visual workplace is a work environment that is self-ordering, self-explaining,.

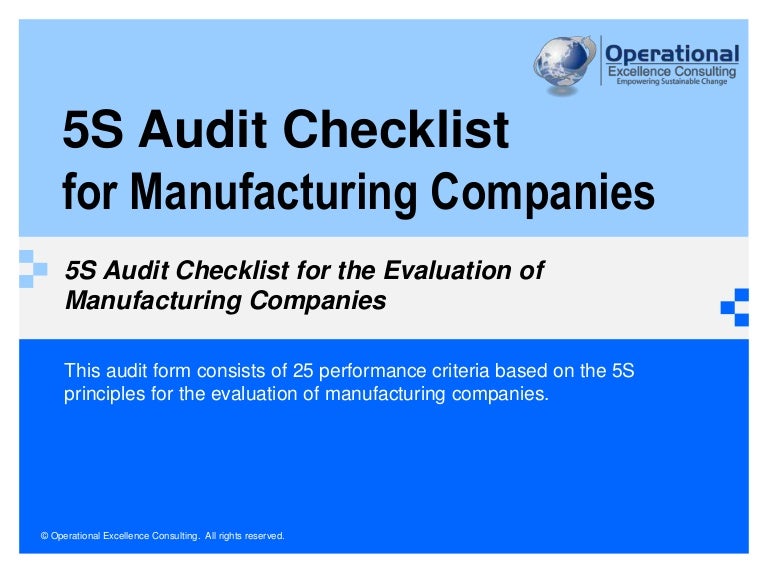

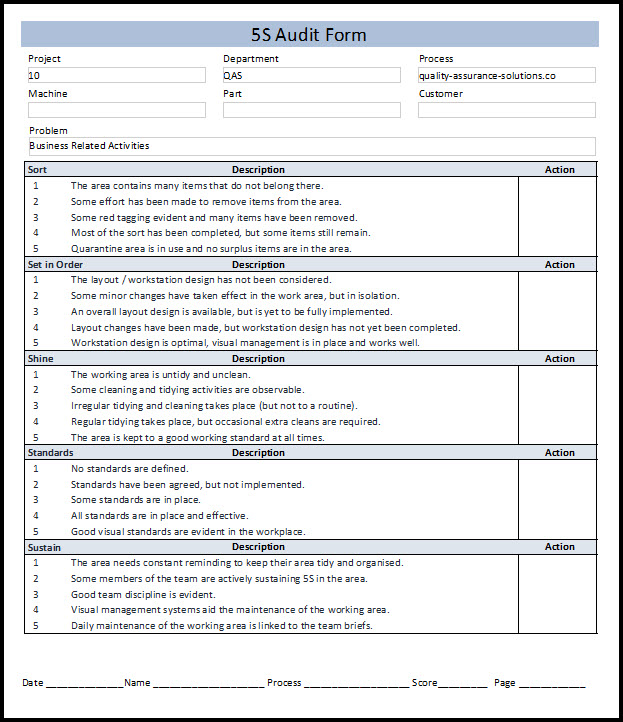

5S are particularly effective because they want to improve the housekeeping of your workshops and the rest of your premises in order to obtain the following advantages :. Periodicaly conduct 5S audits. 5S is a fundamental pillar of a Lean deployment.

Course 1 - Introduction to the 5S Concept (3 Videos) This course provides an overview of 5S, what 5S stands for, and why using 5S is essential to your Lean Journey. For more on harnessing the principles of Six Sigma for the workplace and personal productivity, here’s an insightful article that investigates ways to enhance performance using the principles of Six Sigma. 5S Audit the checksheets.

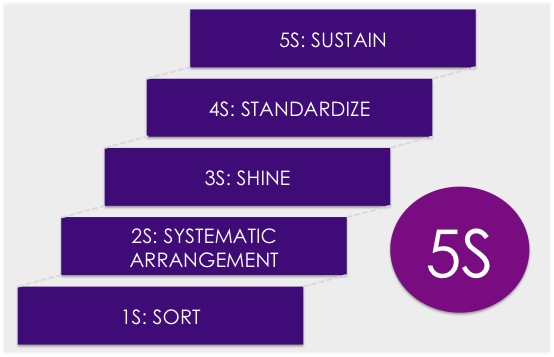

5S is a method of work organized in 5 stages with the goal of significantly improving the order and cleanliness. The Five Lean Principles Explained:. 5s principles were created for lean production, cost reduction and employee empowerment.

The 5S housekeeping system must be supported by top management. These are foundational to Kaizen (continuous improvement) and a manufacturing strategy based. Its aim is to improve the working environment in the organization and the quality.The approach is based on enhancing independence of the employees, on team work and leadership.

Each term starts with an S. What types of organisations benefit from a 5S program?. The 5S exercise captures core principles of the Lean philosophy that facilitate the extension and development of a lasting lean implementation.

Improvement (Kaizen) Principles Summary What is 5S and why do we want to do it?. 5S Audit the locations of all equipment. Relationship between 5S’s and ISO 9001 Applying 5S is a way of implementing ISO 9001:15 clauses 7.1.3 and 7.1.4, which address Infrastructure and Environment for the Operation of Processes.

The 5S Principles are recognized in many industries as effective tools for improving workplace organization, reducing waste and increasing efficiency. The 5S principle is a quality improvement tool used for organizing workspace. However, when implemented in a disciplined manner the above benefits will accrue.

5S Implementation in the Office The 5S management philosophy eliminates waste and improves office organization and standardization. Lean Manufacturing Business Baby Lean Six Sigma Outdoor Crafts Kaizen Tool Kit Garden Tools Workshop Create. The 5s methodology is an innovative management system that encourages the team members to think lean and provides the adoption of Lean principles in the company.

While some think of it as a spring cleaning, and position it as such, it is much more. The Five Lean Principles. Stressful at first, easier as you utilize each S from the 5S method.

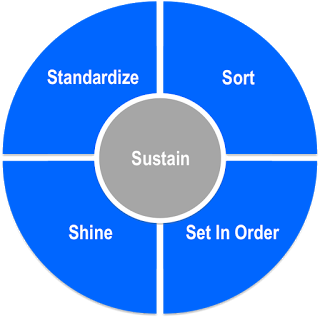

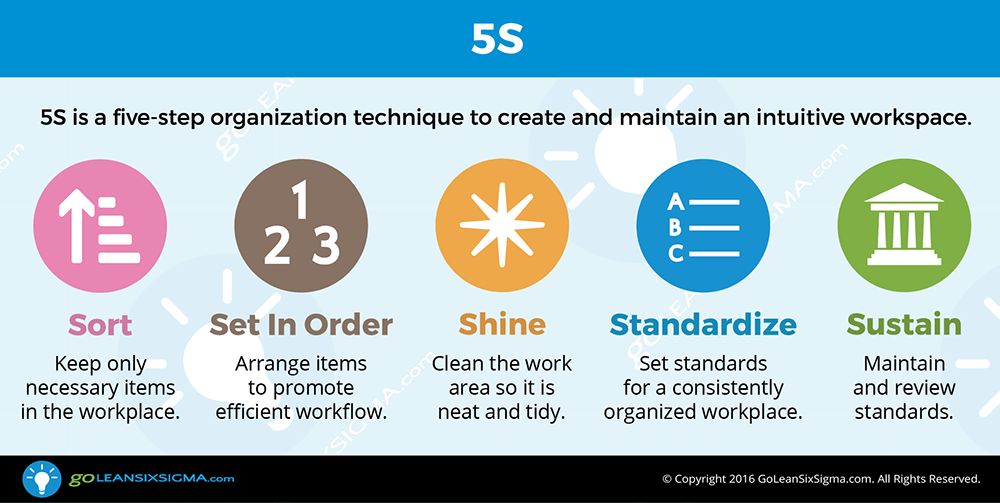

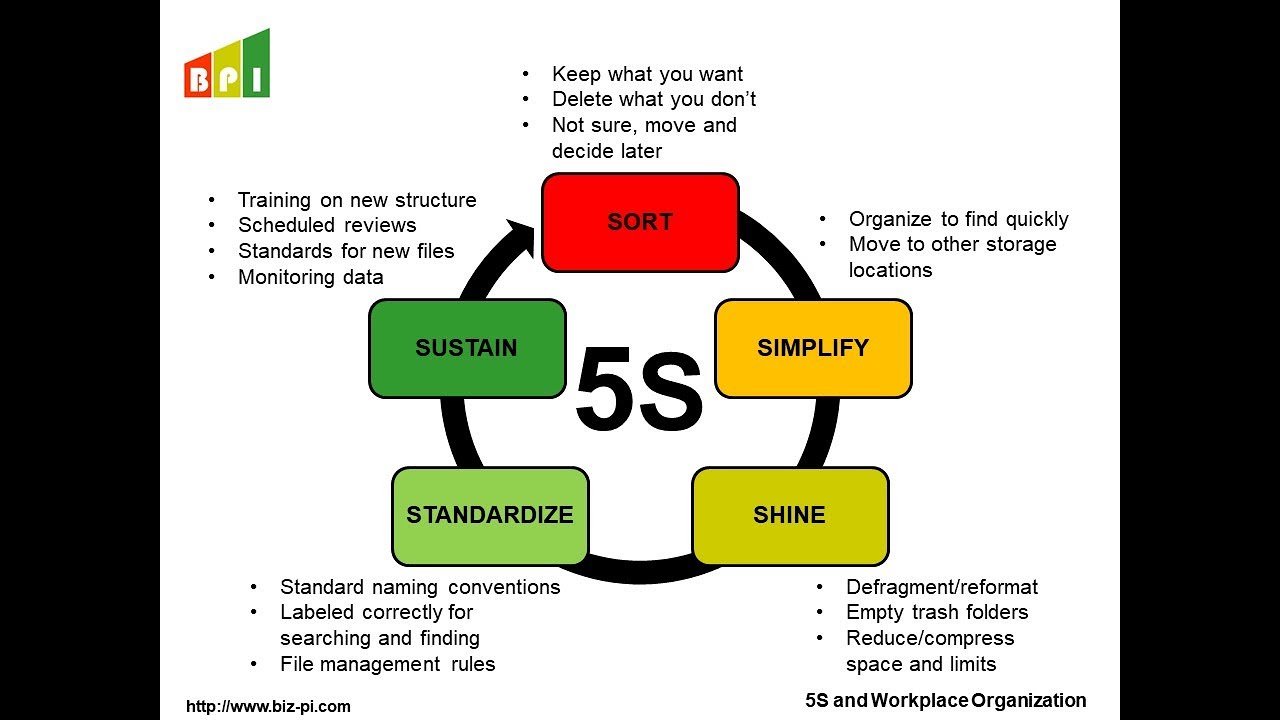

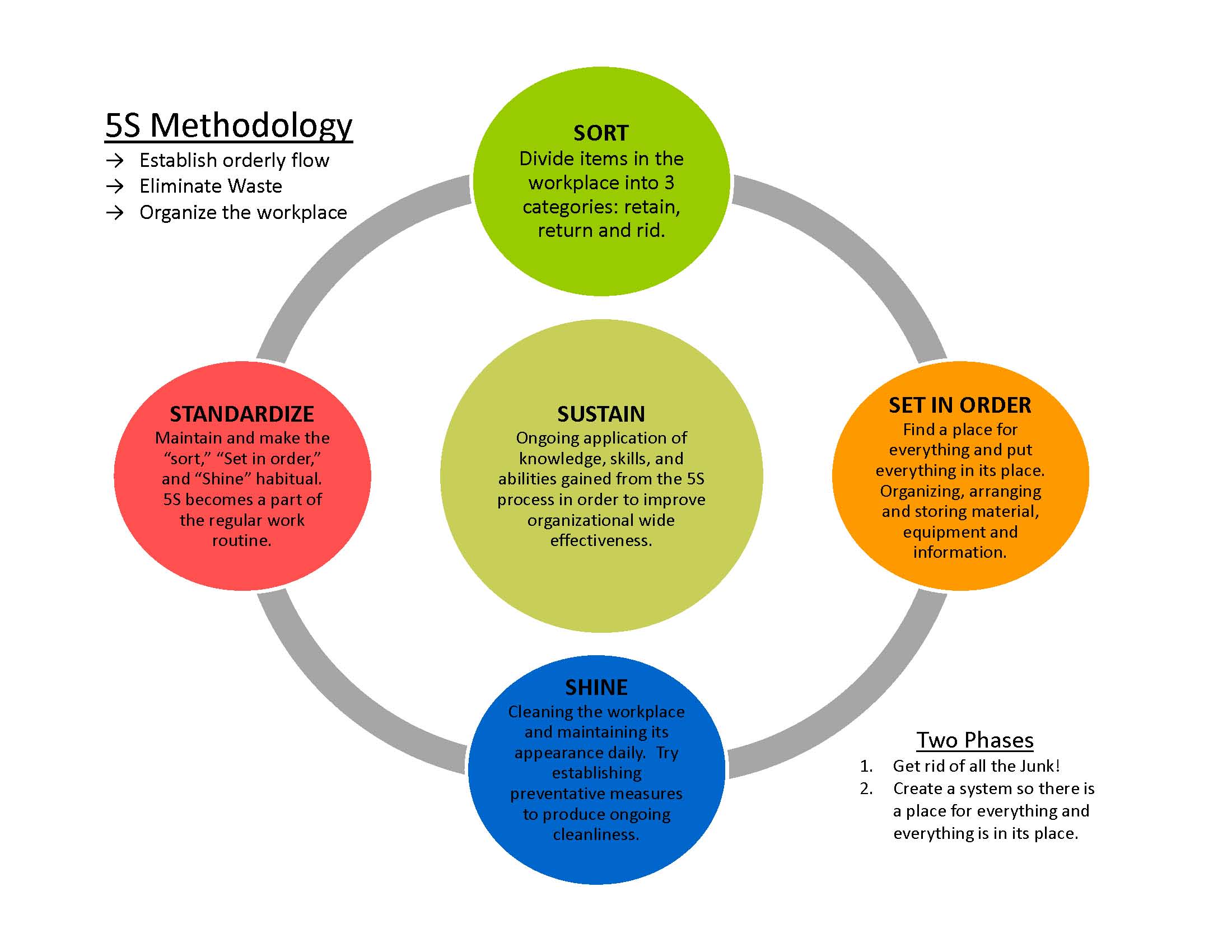

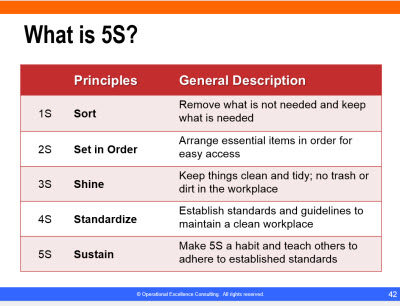

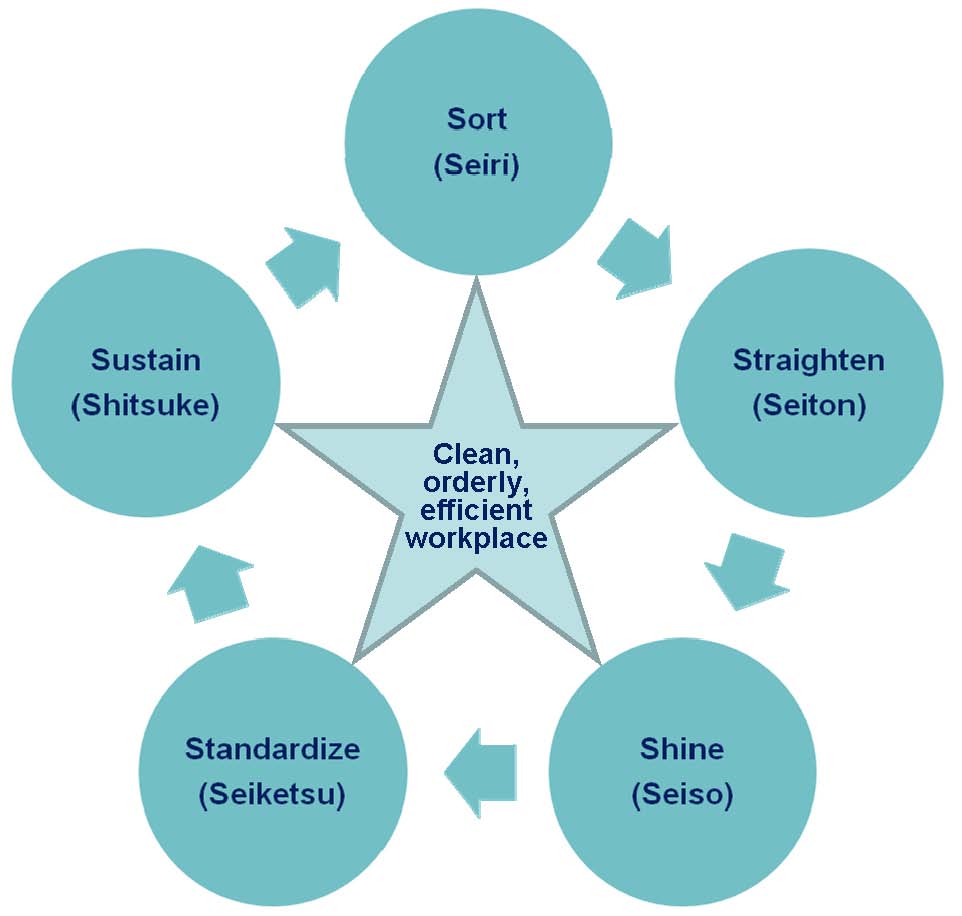

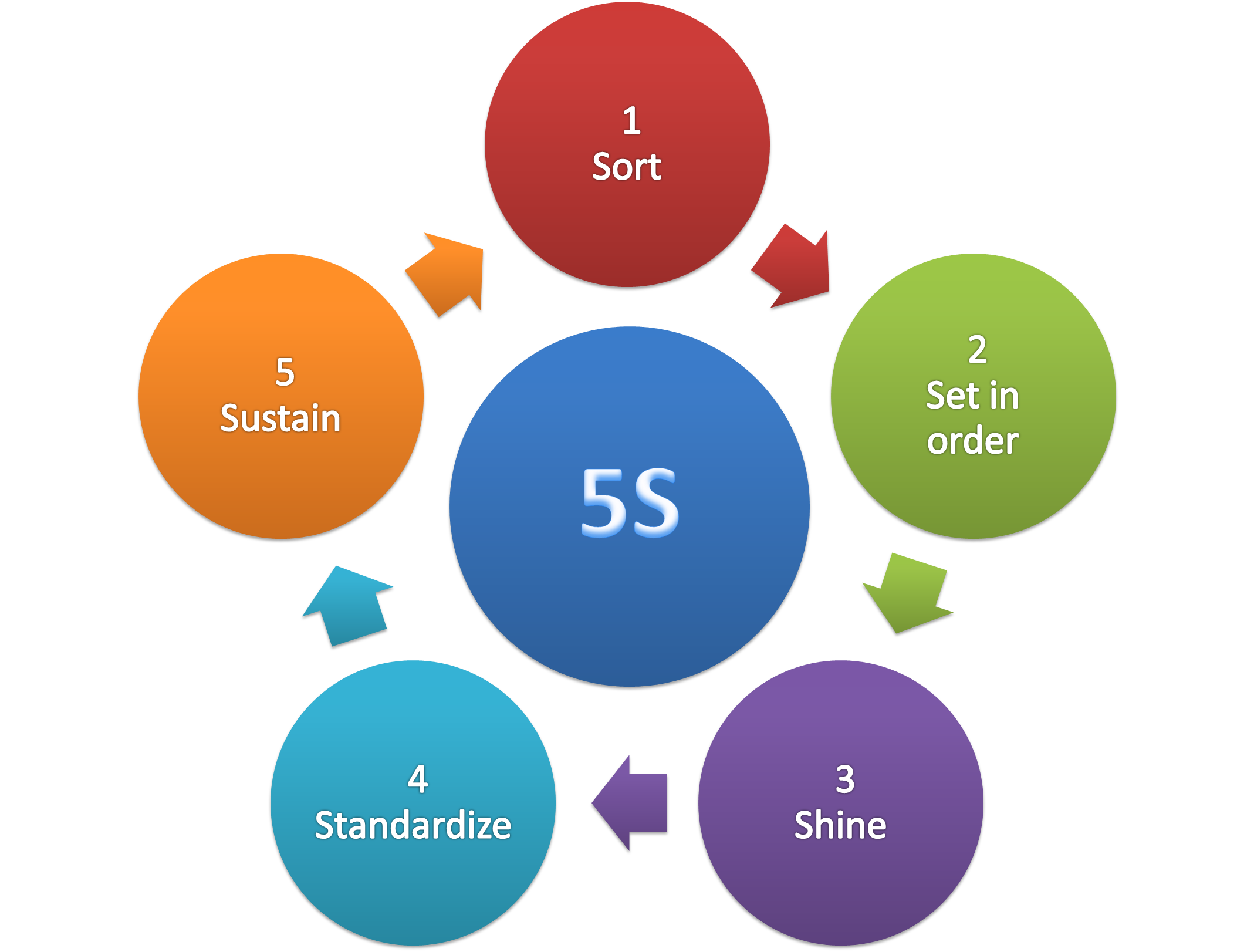

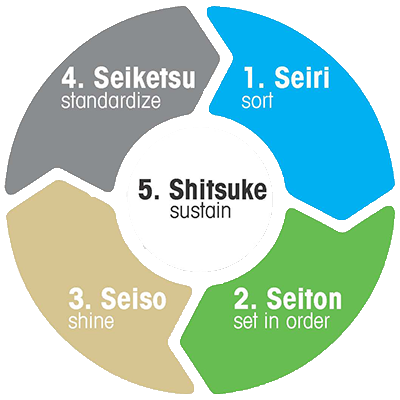

5S represents 5 disciplines for maintaining a visual workplace (visual controls and information systems).These are foundational to continual improvement and a manufacturing strategy based on “ Lean Manufacturing ” (waste removing) concepts. Pioneered by Toyota Motor Company, the 5S method applies standard housekeeping practices in the workplace through the five principles of Sort (seiri), Set in order (seiton), Shine (seiso), Standardize (seiketsu), and Sustain (shitsuke). Learn vocabulary, terms, and more with flashcards, games, and other study tools.

The 5S concept is designed for integration with other Lean tools, including Kanban, Kaizen and Total Productive Maintenance, to create the most efficient workplace possible. This final step helps to maintain the progress built through the first four steps, and eliminates waste by ensuring the waste-saving practices of 5S are adhered to. At its most basic, the 5S concept is designed to improve workplace efficiency through facility-wide organization, cleanliness, and visual communication —reducing costs and boosting productivity.

6 S lean not only helps organizations promote efficient working environments but also establishes a sustainable culture of safety. 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection. THE 5S PRINCIPLES Lean principles 5s aren’t difficult to grasp once a person knows what they are.

It’s widely believed that the principles of 5S originated in Japan during Toyota’s rise to prominence in the 1950s. 5S, sometimes referred to as 5s or Five S, refers to five Japanese terms used to describe the steps of the 5S system of visual management. Promote 5S in a BIG way.

5s and Lean Manufacturing Principles Lean manufacturing as a whole is a production practice that aims to eliminate waste and create value through facility organization. Mike Wilson | July 12, 12 | 2 min read 5S Organized Workplace. To neatly arrange and identify parts and tools for ease of use.

5S – Fundamental Principles of 5S The high visibility, organizational tool, known as 5S, will provide you with the specialized ability you need to remove unnecessary items from your workplace, organizing it to be as efficient and functional as possible. Implementation of this method "cleans up" and organizes the workplace basically in its existing configuration, and it is typically the first lean method which organizations. Adherence to the principles of 5S (Sort, Set in Order, Shine, Standardize and Sustain) will lead to lower costs, improved quality, higher productivity, and improved safety standards.

Everyone thinks they know what housekeeping is, but it's one of the easiest things to overlook, especially when. In the service industry, customer satisfaction plays a key role and 5S can help achieve that target. Now work groups can come up with their own.

The list describes how to organize a work space for efficiency and effectiveness by identifying and storing the items used, maintaining the area and items, and sustaining the new order. It is always good to refresh your memory with the basics of any methodology. • 5S is a philosophy and a way of organizing and managing the workspace and work flow with the intent to improve efficiency by eliminating waste, improving flow and reducing process unreasonableness.

Everyone and all types of business benefit from having a well constructed 5S program. Seiri (整理), seiton (整頓), seisō (清掃), seiketsu (清潔), and shitsuke (躾). 5S Steps Poster Download the 5S guide and get a 5S poster sent to your facility at no extra charge.

The next sections provides a detailed overview of each principle. 整理 (Seiri), 整頓 (Seiton), 清掃 (Seiso), 清潔 (Seiketsu), 躾 (Shitsuke), which have been translated into English roughly as ‘Sort’, ‘Set in Order’, ‘Shine’, ‘Standardize’, and ‘Sustain’. The 5S’s are a standard which is commonly used throughout industries to keep work spaces safe and efficient.

5S is short for:. The fifth of the lean 5S principles is Sustain. In simple terms, the five S methodology helps a workplace remove items that are no longer needed (sort), organize the items to optimize efficiency and flow (straighten), clean the area in order to more easily identify problems (shine), implement color coding and labels to stay consistent with other areas (standardize) and develop behaviors that keep the workplace organized over the long term (sustain).

Visual Workplace and 5S go hand in hand. There are five steps in the system, each starting with the letter S:. The 5S principles are said to originate from Japan, by the Toyota Motor Company.

By providing a systematic framework for organization and cleanliness, 5S helps facilities avoid lost productivity from delayed work or unplanned downtime. 5S Audit the department cleanliness. 5S is a method to improve and sustain workplace organisation.

It is usually manufacturing. 5S also helps in boosting staff morale and improving the company’s image. What are 5S principles?.

It focuses on maintaining cleanliness, safety and efficiency of the workspace. Where ever inefficiencies lie, lean 5s is a wonderful tool and philosophy to create order and motivation in the workplace. 5S - Google Search #5S is the foundation tool which enables all other Lean pillars and #Lean tools to sustain.

Develop a continuous improvement culture that drives excellence and maintains the 5s methodology Ensuring the 5S principles are embedded in training activities;. 5S is an organisation system that prioritises efficiency and effectiveness within the work place. Use banners to capture attention, enhance the support, and spread the message of the program, as they communicate its importance and impact on the company.

It helps to create a highly #VISUAL workplace, which reduces the Through Put Time of the process drastically. 5S Audit the employees knowledge of the 5S. What Are the 5 S's?.

5S, a systematic method for workplace organization, keeps spaces clean and clear of clutter processes. Improve efficiency with effective organization. The 6 S’s in 6S Lean.

As a bonus, the results of this event are immediate and apparent, something that will build excitement among the team and encourage. The 5S system is a lean manufacturing tool that improves workplace efficiency and eliminates waste. 5s Implementation Plan Step 1:.

The principles of 5S originated from five Japanese words:. Like manufacturing, adopting the 5S principles throughout the office and administrative functions increases efficiency. While adhering to the 5S principle of Sort, Set in order, Shine, Standardize, and Sustain, the 6S method adds the concept of Safety.

How Well is Your Business Doing?. The first step is to sort the work area and eliminate any items that are not needed, as this allows employees to see where changes need to be made. 5S is a system to reduce waste and optimize productivity through maintaining an orderly workplace and using visual cues to achieve more consistent operational results.

In Japanese, the five S's are Seiri, Seiton, Seiso, Seiketsu, and Shitsuke. The principles underlying a 5S program at first appear to be simple and obvious common sense. 5S serves as the foundation for continuous improvement activities and provides the base for.

2 min read 5s is the organization of the workplace or a factory that enables the workers to control their work area and eliminate obstacles…. Start studying Lean Exam 1:. The 5s methodology is composed of Sort, Set in Order, Shine, Standardize, and Sustain.

5S Powerpoint Educate your team on with this in-depth presentation on how 5S works and its benefits. Organizations should be careful to not allow the 5S Principles to become viewed as the whole of the company’s improvement efforts. This interactive online course will teach you how to focus the 5S System on safety.

The 5S System is a set of universal principles and activities that sustain high performance in companies in any industry. One of the most prudent business advice from experts that customer satisfaction is the ultimate goal of any business.By giving importance to customer’s needs, a business can improve its product or service quality. The Principles And Benefits Of 5S April 26, 17 General 5S is a process that delivers outstanding results in the areas of quality, productivity, cost, efficiency, and safety.

Sort, Set in Order, Shine, Standardize and Sustain 5S represents 5 disciplines for maintaining a visual workplace (visual controls and information systems). It is for improvement of. With pits having a space constraint of 10 square feet it is important to apply the 5S’s to maximize space, become more efficient, and.

All you need to remember is to keep the 5S maintenance principles as simple and easy to follow as possible. While implementing the Six Sixma Methodology , 5s principles can be used for reducing waste. Once the extra clutter is gone, it's easier to see what's what.

Think of it as the foundation upon which a house is built upon. Lean 5s techniques work from the assembly line to the office. When the workplace is a mess, processes slow down.

According to clause 7.1.3, the infrastructure required to produce a product or provide a service should be maintained. The five principles are considered a recipe for improving workplace efficiency and include:. Understanding and following the 5S System for safety will give you the foundation to improve safety and productivity in your workforce.

Merchandising 5s Principles On Garments Productivity

5s Goleansixsigma Com

5s What Is 5s Methodology Lean Manufacturing Lean Six Sigma Business Leadership

Amazon Com 5s Garage An Introduction To 5s And Lean Principles Movies Tv

Implementation Of 5s Principles In Motokom Velky Meder Sneci

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

5s In The Food Industry Examples And Tips For Implementation Food Safety Magazine

5 Reasons 5s Is A Good Place To Start Your Lean Journey Lean Six Sigma Lean Manufacturing Kaizen

5s Cycle Of Principles And Examples Of Categories Sort Shine Standardize And Set Powerpoint Slide Clipart Example Of Great Ppt Presentations Ppt Graphics

10 Best 5s Images Lean Manufacturing Lean Six Sigma Kaizen

Our 5s Workplace Starbank Panel Products

Qte0iuthnvafcm

Implementing Lean 5s For Construction Projects Keep It Simple And Practical Sysnovate Solutions

Amazon Com 5s Lean Office Poster 22 X 28 Made In The Usa Office Products

Image Result For 5s Principles Of Housekeeping Action Words Housekeeping Lesson Plans

5s Principles Banner Mbr974

3

5s Lean Manufacturing And Six Sigma Definitions

5s Lean Principles Explained John Shufeldt Md

Kaizen Management Training 5s Principles

Seo 5s Japanese Management Principles For Effective Seo Munso

What Is Lean 5s Methodology Training Overview Lean Smarts

5s Or 6s Lean Management Technique Possible Uses In Project Management Ipma International Project Management Association

The 5 Pillar Strategy For A Lean Workplace Biotility

5s Safety

Lean Manufacturing 5s Principles Presentation Pictures Powerpoint Presentation Designs Slide Ppt Graphics Presentation Template Designs

Let S Get Organized How To 5s Your Desk Continuous Improvement Blog

5s Poster

5s Principles 5s News Supplies Products And Reviews For Lean Professional

The 5s System Lean Manufacturing Methodology

5s Principles Processes And Tools For Quality Improvement Dr Aminu

5s Lean Manufacturing And Six Sigma Definitions

10 Best 5s Images Lean Manufacturing Lean Six Sigma Kaizen

5s Lean Flowstore Systems 5s Manufacturing Principles

A Practical Approach To The Successful Practice Of 5s

Amir Zakaria Consulting Group 5s

Image Result For 5s Principles Of Housekeeping

5s S Steps To Shaping Up Principles And Implementation Of Records And Filing Management Platinumlist Net

5s Google Search Lean Manufacturing Lean Six Sigma Lean Enterprise

What Are Some Examples Of 5s Strategies Creative Safety Supply

What Is 5s The Secret To Japanese Success Housekeeping Technique

5s Principles Of Tqm

Five S 5s Principles Source Own Elaboration Based On Download Scientific Diagram

5s Audit Findings Magnetic Overlay For Whiteboards At 5s Store

5s News Supplies Products And Reviews For Lean Professional

5s 5s Methodology Quality One

0314 5s Principles Powerpoint Presentation Ppt Images Gallery Powerpoint Slide Show Powerpoint Presentation Templates

Q Tbn 3aand9gcsgkyuctoovyu8 Dv3rfc7cm Qd1ic281fteiisxua Usqp Cau

5s Principles Storyboard By Austriajp

Software Configuration Management Embracing The Principles Of 5s Cmcrossroads

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

5s Techniques By Operational Excellence Consulting

High Quality 5s Poster

3 Top Ways A 5s Event Brought Order To Our Metal Fabrication Shop Wiley Metal

Implementing The 5s Methodology The First Steps Toward Workplace Efficiency

What Is 5s The Secret To Japanese Success Housekeeping Technique

5s Audit Checklist For Manufacturing Companies By Operational Excelle

Benefits Of 5s Is Lean 5s Just Housekeeping Toughnickel Money

Learn Lean 5s Best Practices

5s Program

5s Organize For Productivity Lean Manufacturing Part 2 Cnccookbook Be A Better Cnc Er

What Is 5s An Explanation Of The Elements Of 5s For A Lean Culture

Defining The 5s Principles In A Workplace 5s News Supplies Products And Reviews For Lean Professional

The 5s Lean Method An Essential Guide For Your Maintenance Facility

Q Tbn 3aand9gcr00pubj9b L0 04nl0ynqx0wzf5sczhzqmwgghvqq Usqp Cau

What Is A 5s Event Kaizen Event Lean Manufacturing Lean 5s

The 5s System Lean Manufacturing Methodology

Q Tbn 3aand9gcsoocfwr2kc9sd2is9pfesvhk S8lxmnub3ng Usqp Cau

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

Lean Tool Series Empower Excellence

5s Methodology Wikipedia

5s In Practice Sort And Straighten Mudamasters

5s Principles Lean Manufacturing Principles Of 5s Ribcon

What Is 5s

Kaizen Management Training 5s Principles

Kaizen Management Training 5s Principles

5s In Lean An Overview Of The Principles In A Nut Shell Fabufacture Uk

5s Principle For Work Improvement Lean 5s

5s Lean Manufacturing And Six Sigma Definitions

Lean Six Sigma Leadership 3 Of 3

5s Priciples Tqm Total Quality Management

Your 5s Project And Using Streamliner Software

The Principles And Benefits Of 5s Tqmi

Boost Productivity With Lean Principles 5s Grainger Knowhow

3

Powerpoint Editable Infographics Charts Of Lean Management Principles And Fundamental Lean Methodology 5 Why Management Infographic Visual Management 5 Whys

What Is 5s Quora

5s Principles And Awareness Quality Management Selangor Malaysia Kuala Lumpur Kl Shah Alam Training Workshop

The 5s System Lean Manufacturing Methodology

A Practical And Effective Guide To Implementing 5s In The Workplace

5s Methodology Lean Management Lean Six Sigma Total Quality Management Eng Youtube

5s Audit Checklist Requirements To Sustain A Lean Laboratory

The 5 S System A How To Guide Reliable Plant

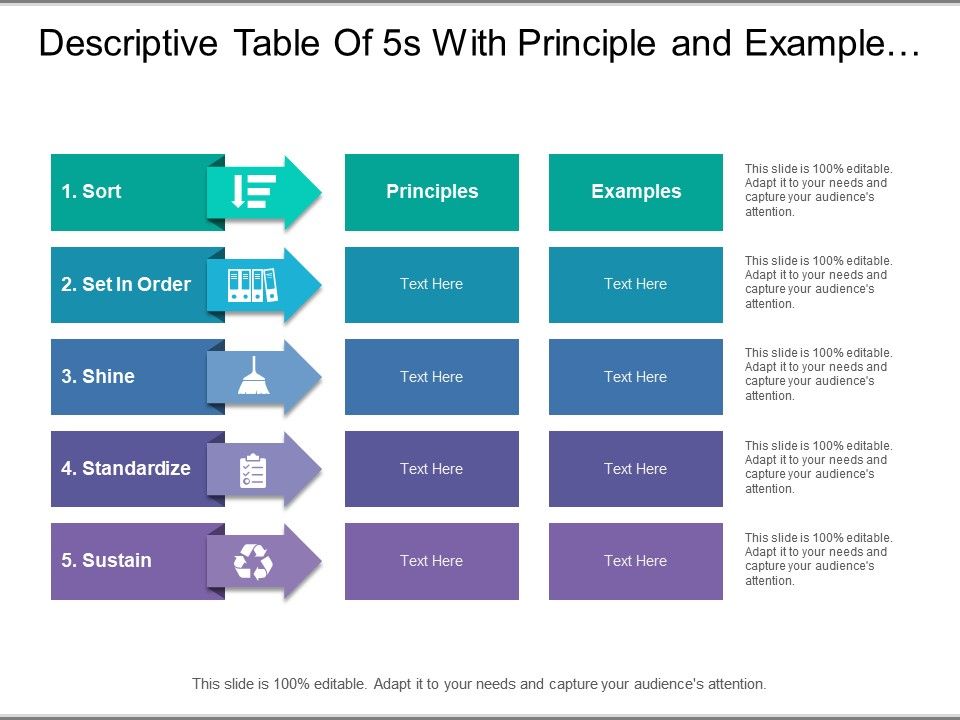

Descriptive Table Of 5s With Principle And Example Of Different Categories Of Sort Shine Standardize And Sustain Ppt Images Gallery Powerpoint Slide Show Powerpoint Presentation Templates

5s System Promoting Workplace Quality And Safety Mahmoud Saad

5s For Workplace Improvement Quality Gurus

5s 5 Pillars For The Visual Workplace The Lean Accountants

Lean Thinking And Methods 5s Sustainability Us Epa