6s Lean

Q Tbn 3aand9gcsuu3yyu7gys Arggerj Spy0wp1dayak9zb50 Hlu Usqp Cau

6s Method Colorado Department Of Transportation

Do Your Processes Require Security Beyond 5s And 6s There S 7s Goleansixsigma Com

Lean 6s Safety Poster Lean Thinking Safetyimages365 Com

6s Lean Workplace Poster Safetycal Inc

Virtual 6s Workplace Organization Go Lean Six

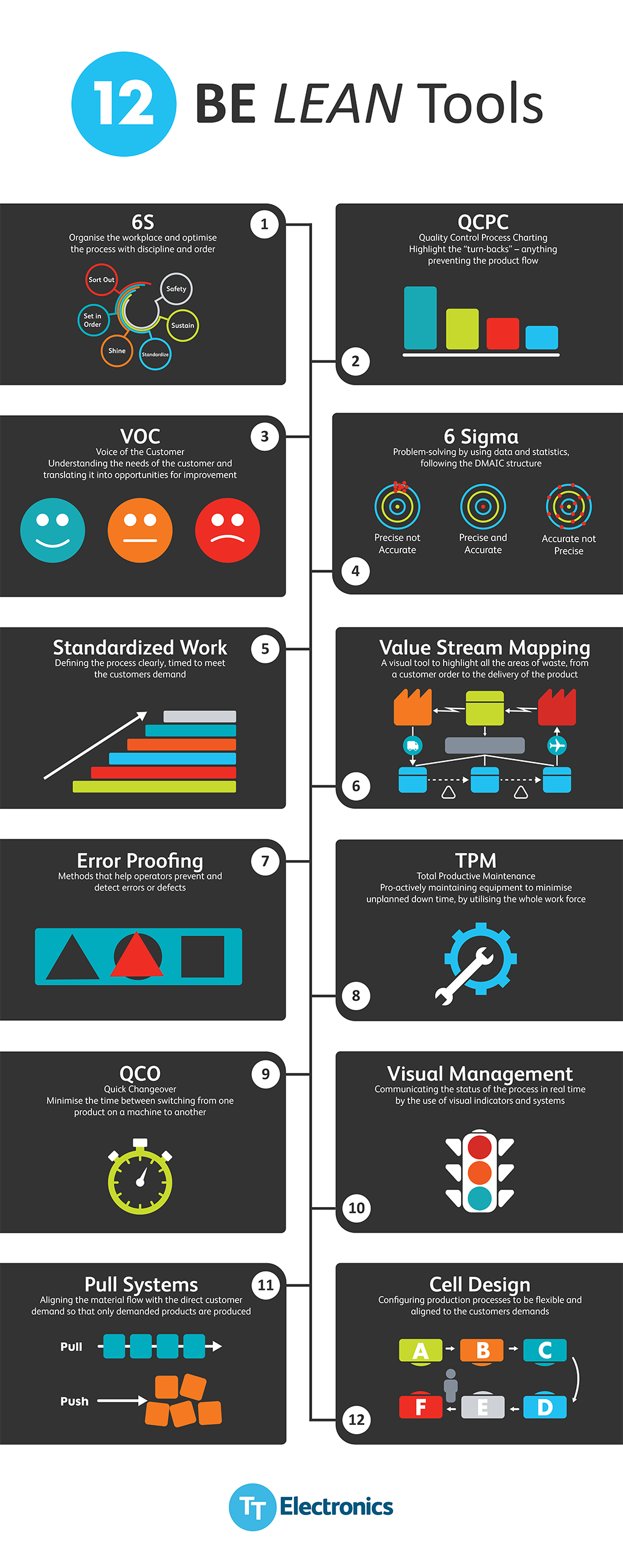

An organization can follow 3 different concepts like Total quality management, 6 Sigma or 6S system to maintain a lean management systematized.

6s lean. Nov 13, 14 - Explore Kelly O'Brien's board "Lean 6s" on Pinterest. A crucial part of the Lean approach is “6S”, a method and set of tools to help us organize workspaces to be effective, efficient and safe. 6S being 5S plus the added step of safety.

22" x 17" 28" x 22" Close. 6S Lean Poster Poster – Large Print, January 1, 13 by Poster (Adapter), Lean Six Sigma Toolbox (Author), 5S Lean Six Sigma (Foreword), Cedro Toro (Illustrator) & 1 more 1.0 out of 5 stars 1 rating. 11X14 Framed This simple but dynamic visual of the 6S lean process serves to educate and remind the lean principles your organization is striving for.

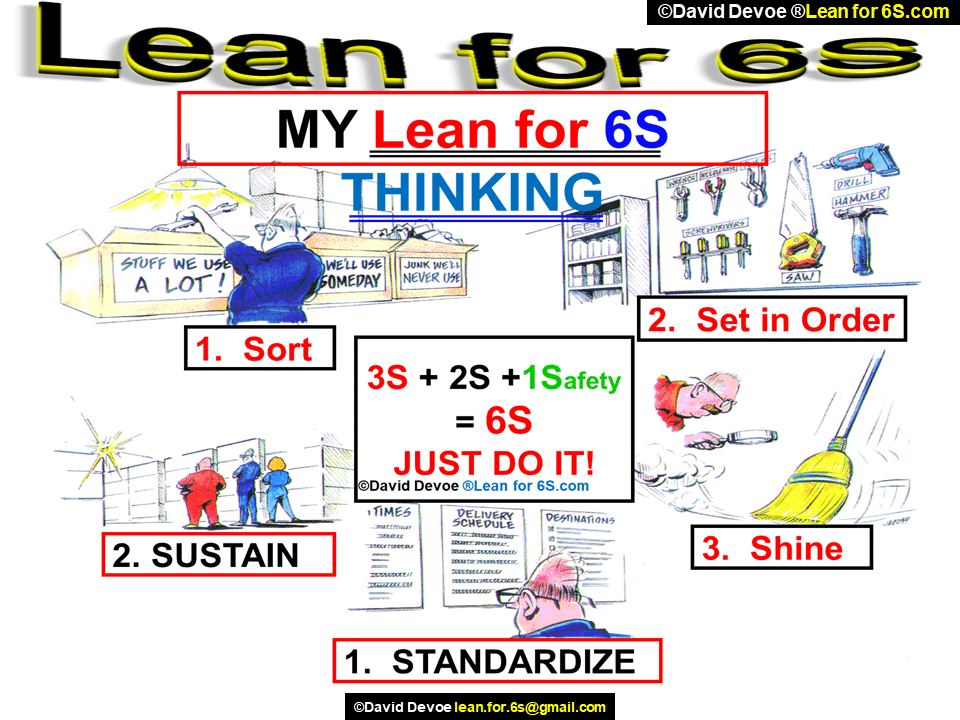

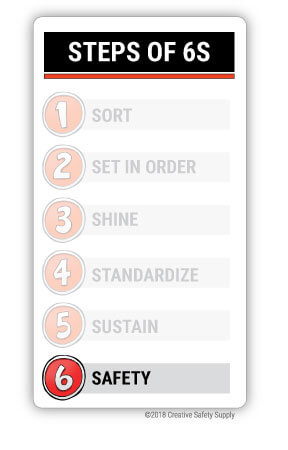

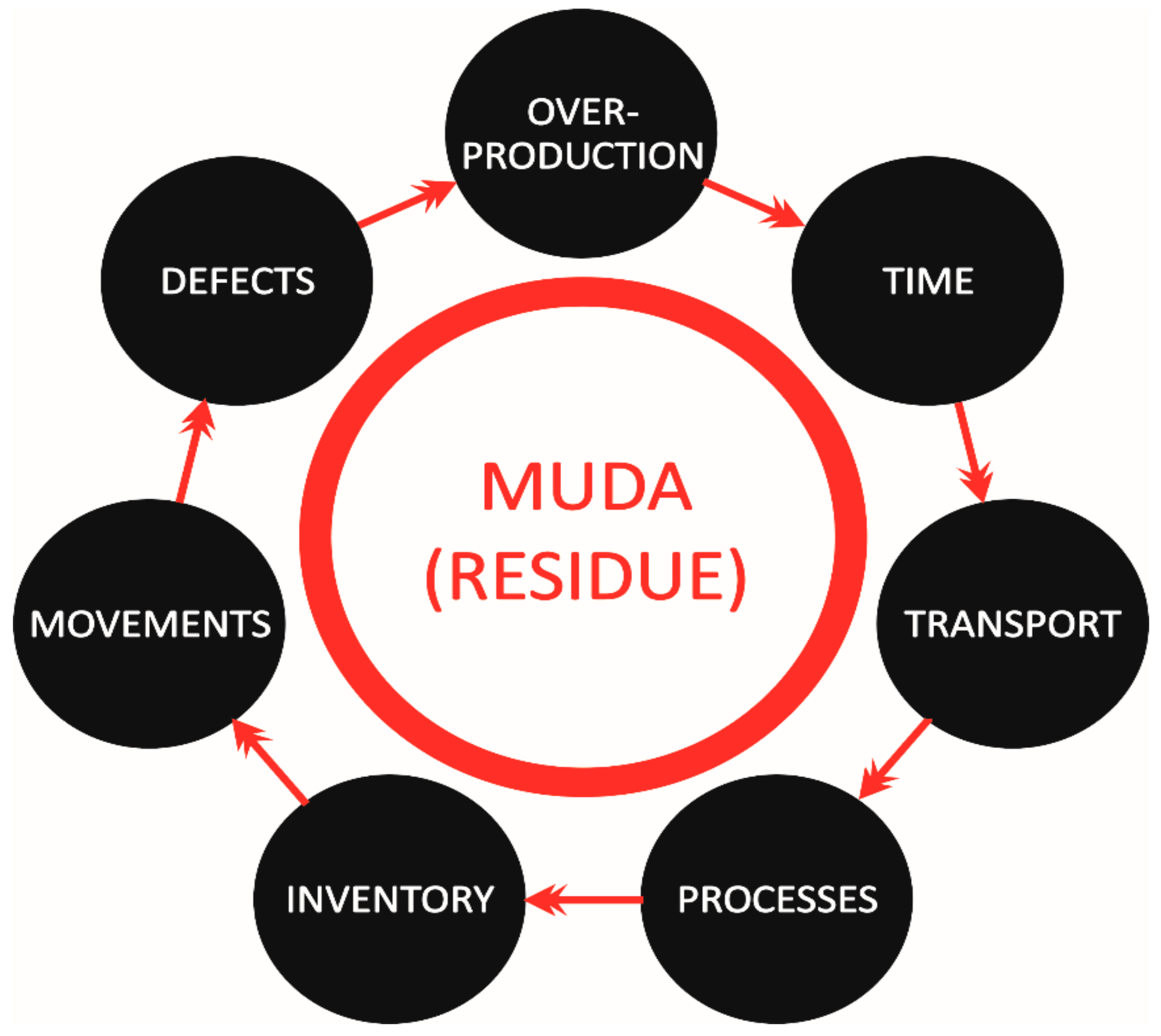

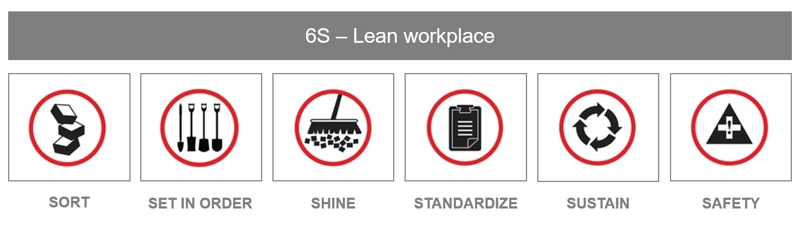

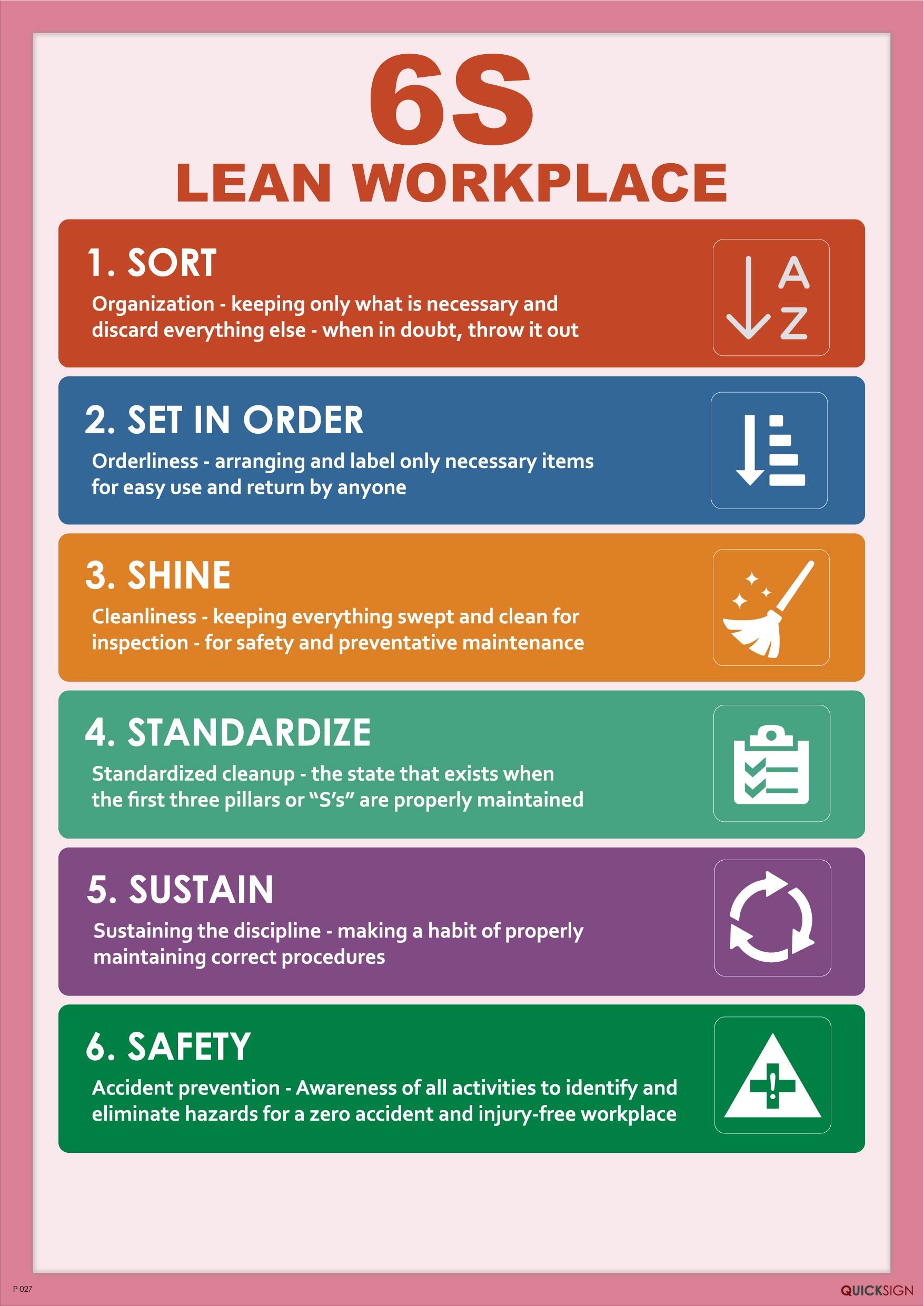

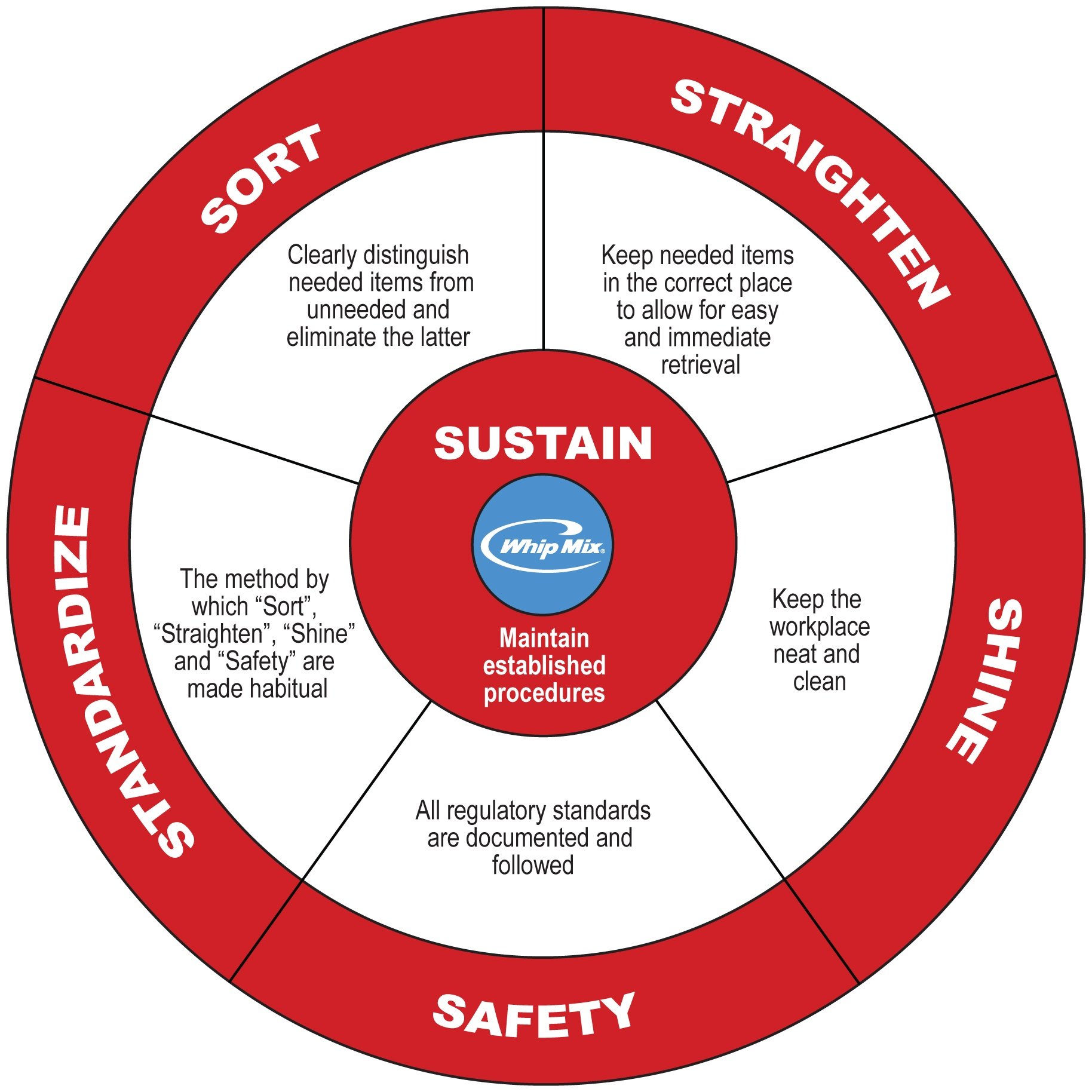

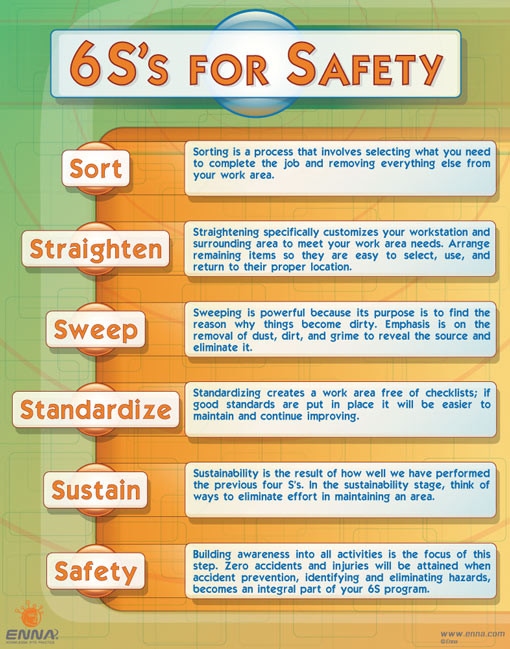

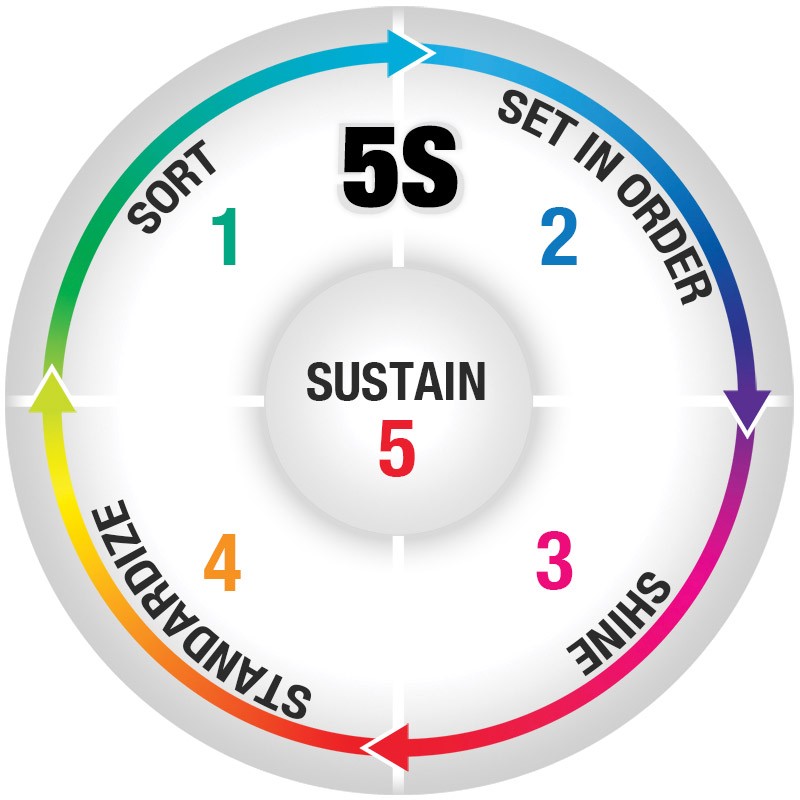

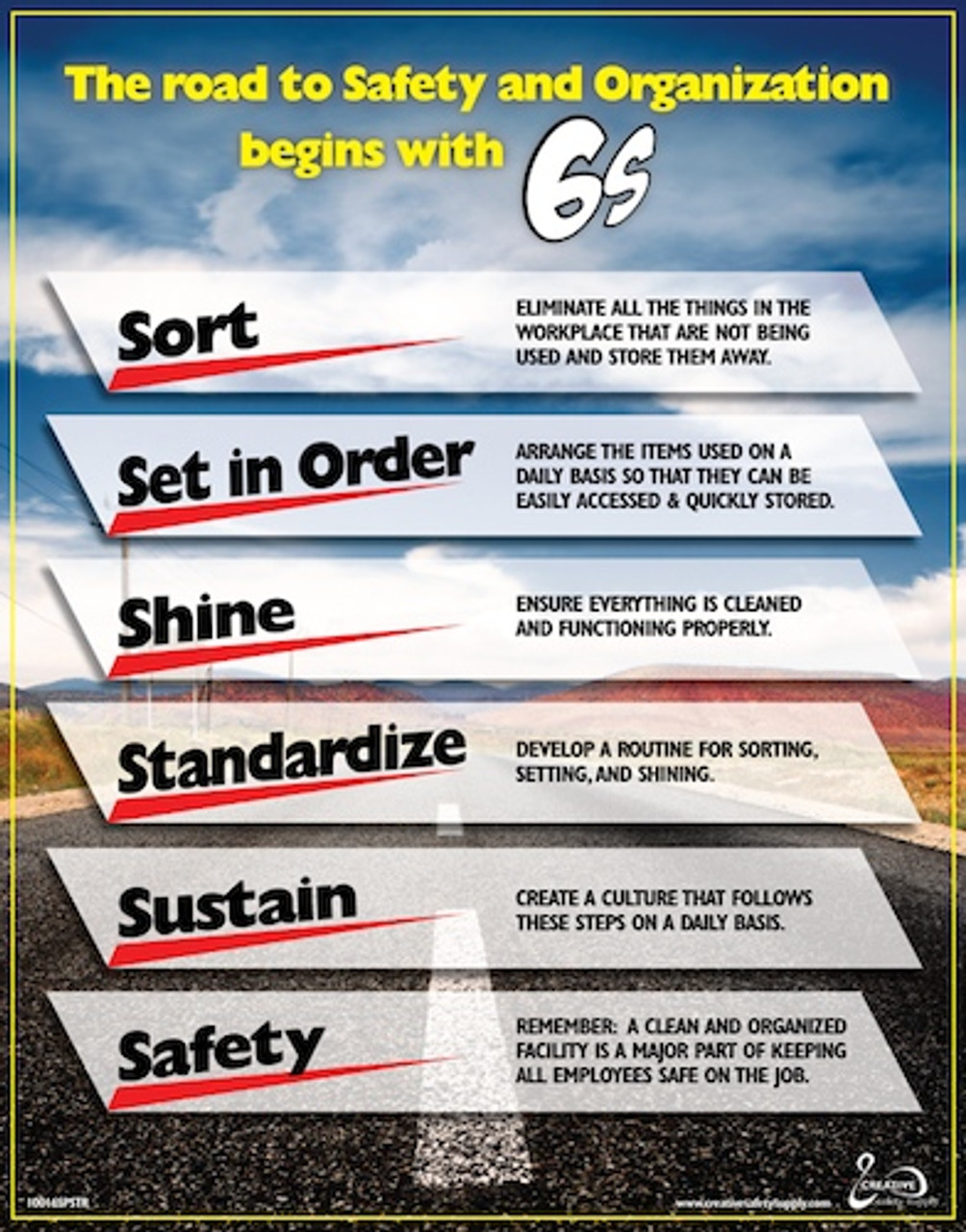

While adhering to the 5S principle of Sort, Set in order, Shine, Standardize, and Sustain, the 6S method adds the concept of Safety. The 6S method is a 6-step process:. 6S (popularly known as 5S + 1) Lean Workplace Checklist is a powerful Lean Manufacturing tool that can be used to optimize the workplace and create the ‘Visual Factory’.The 6S system focuses on reducing waste by maintaining a clean, uncluttered, well organized and safe workplace.

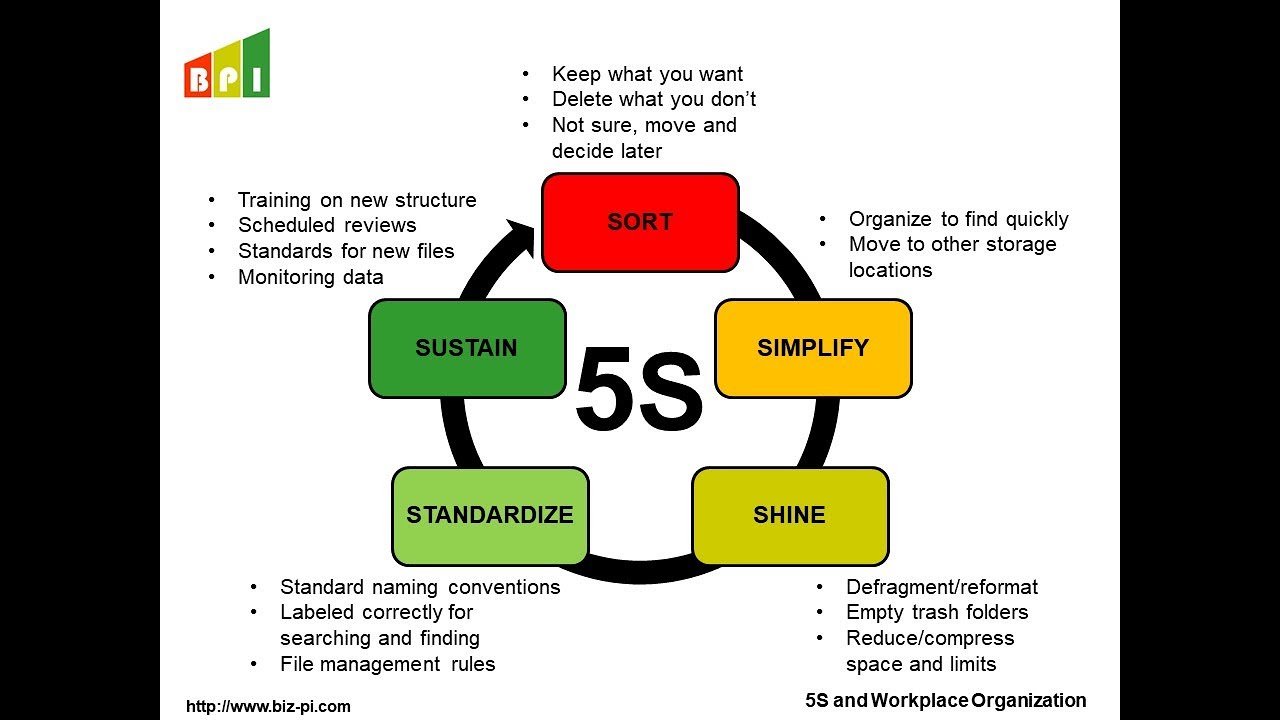

• Identify the steps/sequence of the 6S Process. The output of engineering and design in a lean enterprise is information, the theory behind using 5S here is "Dirty, cluttered, or damaged surfaces attract the eye, which spends a fraction of a second trying to pull useful information from them every time we glance past. 5S is called 5S because their are 5 steps and each step begins with the letter “S” (and/or the sound “s”).

6S may stand for:. As with all Lean tools, 6S is about eliminating waste and maximizing value-added work. In this article, we’ll learn more about 5S and/or 6S and how you can use it to create a more organized, efficient, productive, and safe workplace.

Expand 6S inspections of the Shine pillar to include EHS issues 3. Safety is the additional S to the existing 5S program. It includes color charts, worksheets, checklists, and more.

100% of proceeds go to charity. Lean experts have learned that having a strong safety program in place is as important to the health of a facility as Sort, Set in Order, or and of the other 5S steps. 6S is essentially the 5S System, with a 6th, and very important, S added:.

Does your place of work have materials and WIP all over the place, are tools constantly missing?. In lean product and process development. 5S (or 6S) technique explained 5S (or 6S) denotes 6 key steps in process improvement:.

Seiri, Seiton, Seiso, Seiketsu, Shitsuke and Safety (Tran, 16). 6S Template This tool is used to eliminate waste in your workspace to enable value -added performance. Learning more about what 6S is, and how to implement it in your facility can help benefit your business in many ways.

This full-color, 32-page guide is an essential resource for successfully implementing a lean manufacturing 6S system. This means eliminating search, travel, transporting materials, in- ventory, and hazards. Contains a comprehensive explanation of 6S;.

January 1, 11 By Carlos Conejo. It should be embedded in every decision and the everyday life of an organization. Of Lean 6S principles in the workplace.

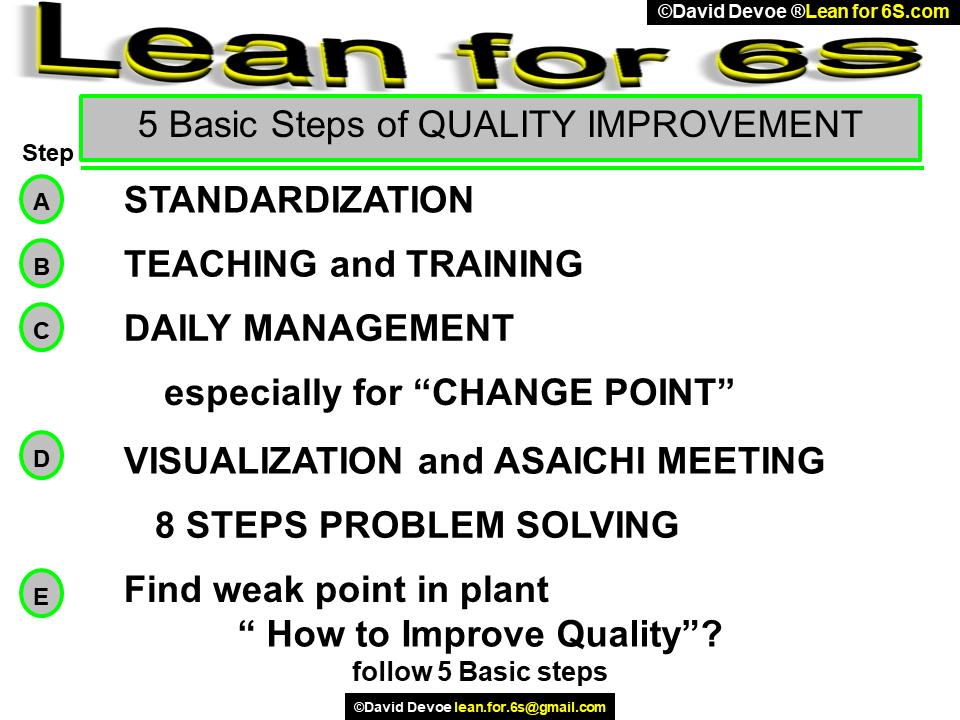

The elements of 6S are simple but very effective. 6S is often the first method companies implement in their Lean journey, since it serves as the foundation of future continual improvement efforts. It is based on the ideas of “Continuous Incremental Improvement” and “Respect for People.” Focus on the fundamentals.

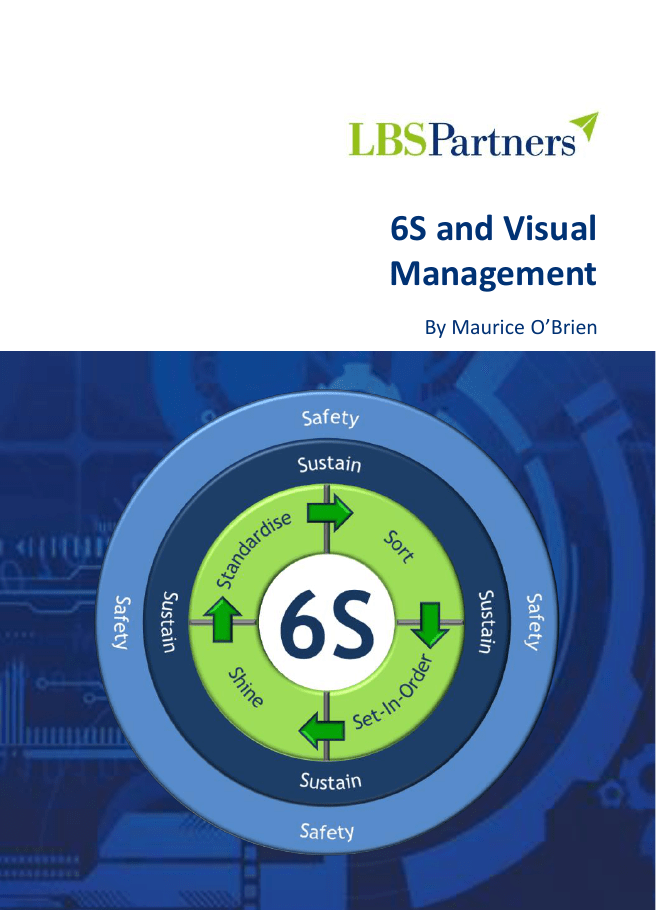

The traditional 5S was expanded to 6S by adding safety awareness directly. 6S is based upon the five pillars (5S) of the visual workplace in the Toyota Production System, plus an overall pillar for safety. Lean Six Sigma methodology is a management approach to improving business performance that has blended the two individual methodologies of LEAN and Six Sigma.Both management strategies are amongst the most used worldwide.They have experienced proven success in a wide variety of industries and services.

Sort Box & Cube Trucks Carts, Trucks, & Hoppers General ID s Marking Paints Marking Tape (Vinyl Tape) Tilt Trucks Trash Bags Trash Cans Utility Carts. Alco has worked to ensure that all areas of the business from the shop floor to the offices consider …. 6S Lean focuses on what can be done to eliminate risks in work processes.

This test is useful for anyone interested in assessing their knowledge of Lean Six Sigma on the Black Belt level. Quality Control Ceiling Banner:. Laboratory staff at all levels, from those in ancillary services to laboratory directors.

Japan manufacturing plants seem to do well using the 5S Methodology as the sustain element does consider safety, but with America having so many workplace safety rules and organizations, that sixth S may be necessary prior to implement 5S in the U.S. These sessions were conducted by Lean Enterprise Estonia, who specialize in dealing with promotion, training and consultancy of lean thinking principles. After completion of this course, the participant will be able to:.

6S Lean Workplace 6S Workplace Solution- Sort, Set, Shine, Standardize, Sustain & Safety. 6S (5S + Safety) and Chemical Management. 6S Lean Poster - Version 4 6S Lean Poster - Sort, Set in Order, Shine, Standardize, Sustain & Safety.

6S methodologies, is the necessary sixth S or safety element only required in the United States?. One of the most common of the 6S systems results from adding Safety to 5S. 6S Lean Workplace - Sort - Set In Or.

Need to help promoting your 6S program throughout your facility?. The main purpose of Lean management is creating value to the customer by optimizing resources. When it comes to comparing 5S vs.

Five S’s (5S) 5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. With the assistance of quality improvement consultants, the "6S Lean" model was applied to the current operation of the emergency eye clinic examination rooms. 6S Lean Workplace Posters- Sort, Set In Order, Shine, Standardize, Sustain, Safety.

This means eliminating search, travel, transporting materials, inventory, and hazards. The lean 6S methodology, which comprises of 5S + safety, is a powerful and effective lean improvement tool which can be applied to any type or size of organisation. To this end, 6S uses its process to create and maintain an organized, clean, safe, and efficient setting that enables the highest level of value- added performance.

Remember 6S For A Lean Workplace. Lean is a customer-centric methodology used to continuously improve any process through the elimination of waste in everything you do;. Lean Six Sigma for Good:.

Continuous improvement is a major part of Lean management, ensuring that every employee is involved in the process of improving. Lean refers to maintaining a zero waste environment. Lean and Environment Toolkit | January 06 | Slide 9 9 Tools for Incorporating EHS into 6S 1.

6S is often the first method companies implement in the Lean journey, since it serves as the foundation of future continuous improvement efforts. This 6S Lean Workplace List Poster is a full color high quality poster will help with the daily 6S reminder. This paper reports the implementation of lean 6S technique in a Parker manufacturing plant in Houston, Texas.

Sort (Seiri) – Eliminate all the things in the workspace that are not being used and store them away. Sort - Distinguish between necessary and unnecessary material, documents, equipment, data, and information. What are the Five S's (5S) of Lean.

What is Lean 6S Many companies will tell you that they implement lean 6S;. Take Advantage Of Our Free Resources!. One such method that was implemented in early 17 was a Lean manufacturing tool called 6S.

Shine Brooms Cleaners Floor Cleaners Mops. Looking for Free Six Sigma Training Online?. This model, considering 8 waste categories, was then used to recommend and implement changes to the examination rooms and to workplace protocols to enhance efficiency and safety.

Using 5S reduces waste (a fundamental goal in lean manufacturing), improves safety (see our article on Lean 6S Safety), and otherwise improves your production process and work environment. 6S (the expanded and improved version of 5S) is a proven strategy for improving your organization, and eliminating waste. Expand 6S audits performed as part of the Sustain pillar to include EHS issues 4.

6S Lean Workplace List Poster. See more ideas about Lean six sigma, Lean manufacturing, Lean sigma. Parker corporate management believes that 6s establishes the foundation for all productivity, quality, safety, and cost improvements of the future.

On our What is 5S?. Our Free Six Sigma Training and Reference Manuals Are Constantly Updated With Recent Industry Changes. The Lean Six Sigma (LSS) tool 6S has long been used by LSS practitioners as a tool for organizing work spaces from shop floors to operating rooms.

Register / Sign In • Track Order. Implement 6S with Our Step-by-Step Guide. 6S Lean Workplace - Sort - Set In Or.

To this end, 6S uses its process to create and maintain an organized, clean, safe, and efficient setting that enables the highest level of value-added performance. By applying the 6S’ you will organize, eliminate unneeded materials and enable the continued maintenance of the improved workspace. The pillars of 6S The 6s Methodology includes familiar steps found in 5s (Sort, Set in Order, Shine, Standardize, Sustain), but adds the concept of Safety.

The 6S System – a Key Lean Manufacturing Tool at the Foundation of Continuous Improvement Initiatives. Just like you’d start with the foundation when building a house, the foundation of our Continuous Improvement efforts, is the 6S System. 6S is a method used to create and maintain a clean, orderly, and safe work environment.

6S is based upon the five pillars (5S) of the visual workplace in the Toyota Production System, plus a separate pillar for safety. This tool can also have tremendous value in organizing an area where many workers spend the majority of their work time – the electronic workspace. Ron Pereira, managing partner for online training company Gemba Academy, called the debate a "hot topic" for those in the lean manufacturing arena.

Use the 6S Lean Safety Checklist to identify hazards or potential risks while performing tasks in the workplace. Page, we learn that the first 5S's stand for:. Set in Order (Seiton) – Arrange the items used on a daily basis so that they can be easily accessed and quickly.

As with all Lean tools, 6S is about eliminating waste and maxi- mizing value-added work. 6 S lean not only helps organizations promote efficient working environments but also establishes a sustainable culture of safety. Straighten Bins Cabinets Label Holders Racks Service & Shelf Carts Shelving Tool Chests.

6S - Sort, Set, Shine, Standardize, Sustain, and Safety. 6S (otherwise known as 5S + Safety) is a method used to create and maintain a clean, orderly, and safe work environment. • Identify 6S as a form of LEAN management.

6S Lean Workplace - Sort - Set In Order - Shine - Standardize - Sustain - Safety. 5S (or 6S) is a lean diagnostic technique (developed as a quality management methodology in Japan) aimed at optimization of the workplace environment and efficiency of work performance. Lean management principles aims to create a stable workflow based on actual customer’s demand.

Use yellow-tagging to identify EHS issues during the Sort process 2. 5S is a formulaic method you can use to straighten and organize a work area. Each of the 6S pillars is relevant to chemical management.

6S (otherwise known as 5S + Safety) is a system that aims to promote and sustain a high level of productivity and safety throughout a workspace. It is a. 6S, or 5S + Safety, is a method used to create and maintain a clean, orderly, and safe work environment.

How does 6S differ from 5S?. We offer Six Sigma PDF Training Manuals For All Lean Six Sigma Training Levels. This is sometimes called 5S+, 6S, lean 6S, 6S safety, or lean 6S safety.

An essential update to the 5S program, 6S adds the vital stage of Safety to Lean manufacturing’s foundational method. Lessons from the Gemba (Volume 1) is a collection of stories and case studies about applying LSS to not-for-profit organizations. To help you through this process, we’ve created an illustrated step-by-step guide to the 6S system.

It can be used in preparation for the ASQ Certified Six Sigma Black Belt (CSSBB) exam or for any number of other certifications, including at private company (GE, Motorola, etc.) certifications. 6s For A Lean Workplace. Follow Us • 978-842-4610 • Contact Us.

Now available on Amazon as paperback or eBook. The traditional 5S was expanded. Jamming it into 5S to make it 6S makes safety seem like a 'program,' which it should not be.

5S Lean Benefits Poster 5S Benefits poster. Understand how step six for safety is key for a successful 6S system. 6S (music), key signature of six sharps 6S (radiative transfer code), a computer program that simulates the reflection of solar radiation 6S / SsrS RNA, the first noncoding RNA to be sequenced 6S, a modification of the 5S methodology which includes "Safety" as the 6th S.

The 6 S’s include Safety, Sort, Set, Shine, Standardise and Sustain.

Leveling Up To 6s Lean Safety Corvex Blog

Lean Chemicals Toolkit Chapter 5 Sustainability Us Epa

5s 6s Rapid Improvement Events American Lean Consulting

High Quality 6s Poster

Leading Edge Group Lean Healthcare Leading A 6s Initiative

3

6s Tutorial For Lean Approach

5s Safety Lean 6s Safety Convergence Training

5s And 6s Lean Manufacturing Our Business Is Protecting Yours

5s Or 6s 5s News Supplies Products And Reviews For Lean Professional

Organizing Your Lab With Lean 6 Sigma Principles Training Source

6s Tutorial For Lean Approach

Organize The Health Care Workplace With A Lean 6s Program Schulich Executive Education Centre

High Quality 6s Poster

Lean Manufacturing Principles From Concept To Implementation

Less Is More Practicing Lean Six Sigma Escatec

Amazon Com 6s To Success Lean Poster 11 X 14 Framed Made In The Usa Posters Prints

6s Poster Remember 6s For A Lean Workplace Sp1247

Lean Six Sigma Tool Box With Images Lean Six Sigma Six Sigma Tools Project Management

W1 Assignment Lean Six Sigma Course 6s And V Chegg Com

5s Vs 6s Utah Lean Six Sigma

Six Sigma 6s Diagram Powerpoint Template And Keynote Slide Slidebazaar

6s Remember For A Lean Workplace Banner Creative Safety Supply

A Lean Journey The 6 Pillars Of 6s Free Posters

Q Tbn 3aand9gcra3svgpkpvlbk 6bmzfr1hwdbw62tkifp8ztyjov2b5lar5ifr Usqp Cau

Six Sigma 6s Powerpoint Diagram Slidemodel

5s Safety Lean 6s Safety Convergence Training

Lean Transformations At Sonoco Hazelwood Workforce Solutions Group St Louis Community College

6s Workplace Banner Remember 6s For A Lean Workplace 28 X 8 Ceilblue

Poster 6s For Success For Sale At The5sstore Com

The 3s Of The 5s Leanfor6s Com

Lean Operations Evaluation The Boxmaker

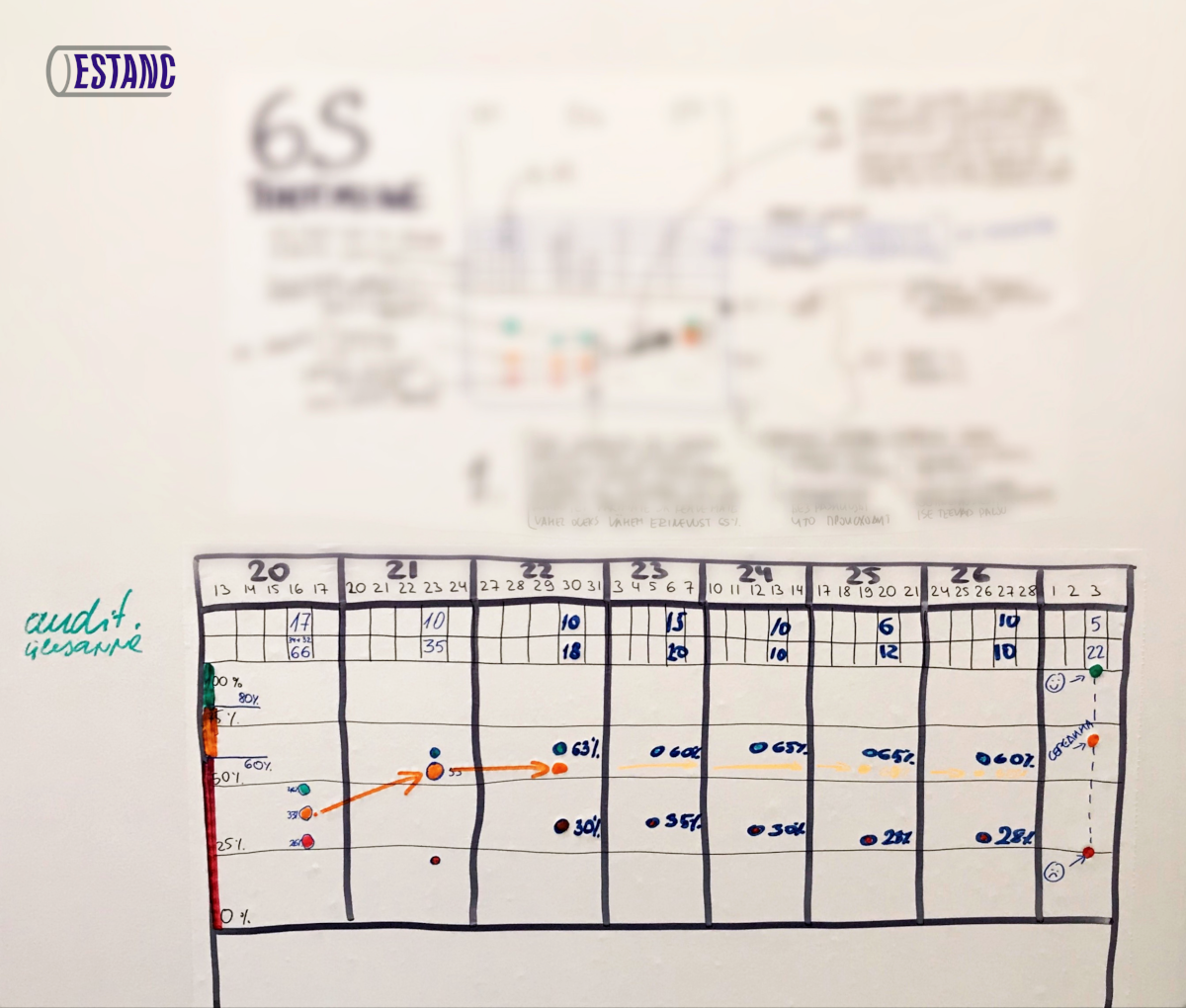

Implementing 6s Lean Methodology In Our Production Plant Estanc

6s Safety Creative Safety Supply

6s Meaning Clipart Lean Manufacturing Gemba 5s Clipart Text Product Line Transparent Clip Art

5s Or 6s What S The Safe Choice

Sustainability Free Full Text Extension Of The Lean 5s Methodology To 6s With An Additional Layer To Ensure Occupational Safety And Health Levels Html

Safety Culture Responsibility

5s Lean Manufacturing And Six Sigma Definitions

6s Lean Workplace Quicksign Product Info

Poster Lean Workplace List For Sale At The5sstore Com

6s Lean Workplace 1 Sort 2 Set In Order 3 Shine 4 Standarize 5 Sustain 6 Safety 24 X 18 Pst5 Jendco Safety Supply

Amazon Com 6s Lean Benefits Poster 11 X 14 Made In The Usa Office Products

6s Poster Leanbreakthru Consulting Group

Los Angeles Lean Six Sigma Certification Azora Leadership

Lean 6s 5s Safety

6s Area Sign 5s Supplies Llc

Lean 6s 5s Safety Global Wizdom

Moving From 5s To 6s Naem

6s Lean Workplace Gnowbelearn

Lean How To Achieve Success Using 6s

6s Audit 5s 1 Lean Workplace Checklist Reviqo

Q Tbn 3aand9gcri68r4l8tqi196t R1xloy164cuv2svr6mxinwdlq2p8ogod6 Usqp Cau

6s Stickers Management Workshop Signage Management Office 5s Quality Management Of Production Safety Placard Sticker Slogan Posters Lean Production Factory Management Wall Charts Corporate Culture

6sing Your Dental Lab Starting A Lean Manufacturing Process Webinar

5 Basic Steps Of The Continuous Improvement Process Leanfor6s Com

Square Payment Test Kpi Fire

6s And Visual Management

Summit Safety Llc Are You Practicing 5s 6s Or Lean In Your Facility

Safety Is The Key To 6s Workplace Standardization Mastercontrol

Lean 6s Training Mercy Medical Center Welcome To Lean 6s Training Ppt Video Online Download

6s Poster 6s Lean Workplace Sp1248

Amazon Com 6s Lean Workplace Poster 11 X 14 Framed Made In The Usa Office Products

6s Lean Workplace Temasek Polytechnic

Robot Check Six Sigma Tools Lean Six Sigma Project Management Tools

6s S For Safety Version 1 Lean Workshop Poster Enna Com

6s Lean Safety Checklist Safetyculture

High Quality 6s Poster

Lean Environment Toolkit Chapter 5 Sustainability Us Epa

6s Lean Workplace Sort Set In Order Shine Standardize Sustain Sa Safety Poster

Institute Of Industrial And Systems Engineers Georgia Tech Iise Chapter Register For Lean 2 29 And Six Sigma 3 7 Today Rsvp Tinyurl Com 6s Lean Six Sigma And Lean Are Important Concepts For Every

5s Methodology 6s Health And Safety Poster Lean Sigma Lean Manufacturing

Useful Six Sigma Method Template Slidemodel

6s Audit Draft Lean Manufacturing Leadership

Do Your Processes Require Security Beyond 5s And 6s There S 7s Goleansixsigma Com

What Is 6s Lean 5s Safety

Lean Focus Introduction To 6s Visual Management Youtube

5s Or 6s Lean Management Technique Possible Uses In Project Management Ipma International Project Management Association

6s Information 6s System 6s Program Guide And Pdf

Safety Banners 6s Lean Workplace The 6 S S For Sale At 5s Store

Lean Garvey Conveyors

Lean 6s Management System Lean Refers To Maintaining A Zero Waste By Liveroom Medium

6s Lean Workplace 5s Poster Safety Poster

5s Sort Set Shine Standardize Sustain

6s For Safety Poster Lean And 5s Posters Also Available Custom Signs And Posters Too

Buy Accuform Mbr987 6s Banner 6s Lean Workplace Sort Set In Order Mega Depot

Lean 6s Safety Poster 6s For A Lean Workplace 3 Safetyimages365 Com

Vulcan S New 6s Method Starts With Safety In Manufacturing

6s Poster 6s Lean Workplace Diagram Sp

6s Remember For A Lean Workplace 28 X 8 Ft Mbr327 Jendco Safety Supply

Six Sigma 6s Diagram Powerpoint Template And Keynote Slide Slidebazaar

High Quality 6s Poster

Implementing 6s Lean Methodology In Our Production Plant Estanc

Lean 6s 5s Safety

Finix 6s Lean

6s Workplace Banner 5s Lean Workplace Chart 28 X 8 Ceilblue

Poster 6s Remember For Sale At The5sstore Com

6s Poster