5s Examples

5s Audit Templates Mudamasters

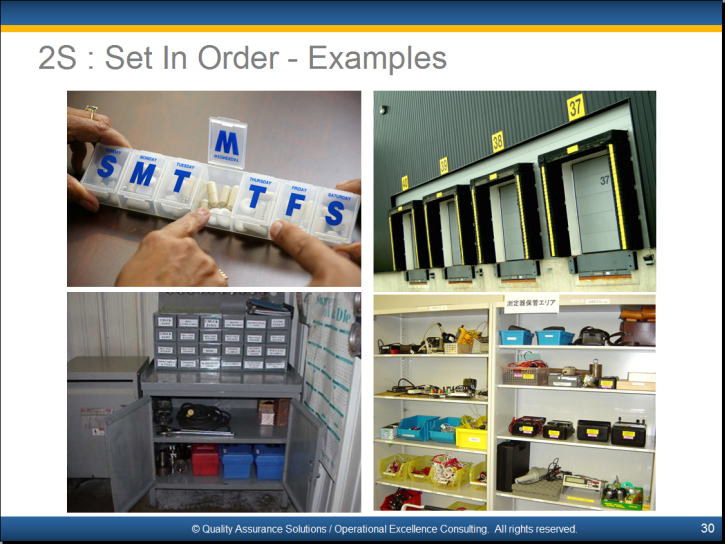

Lean 5s Seiton Straighten Simplify Set In Order Configure

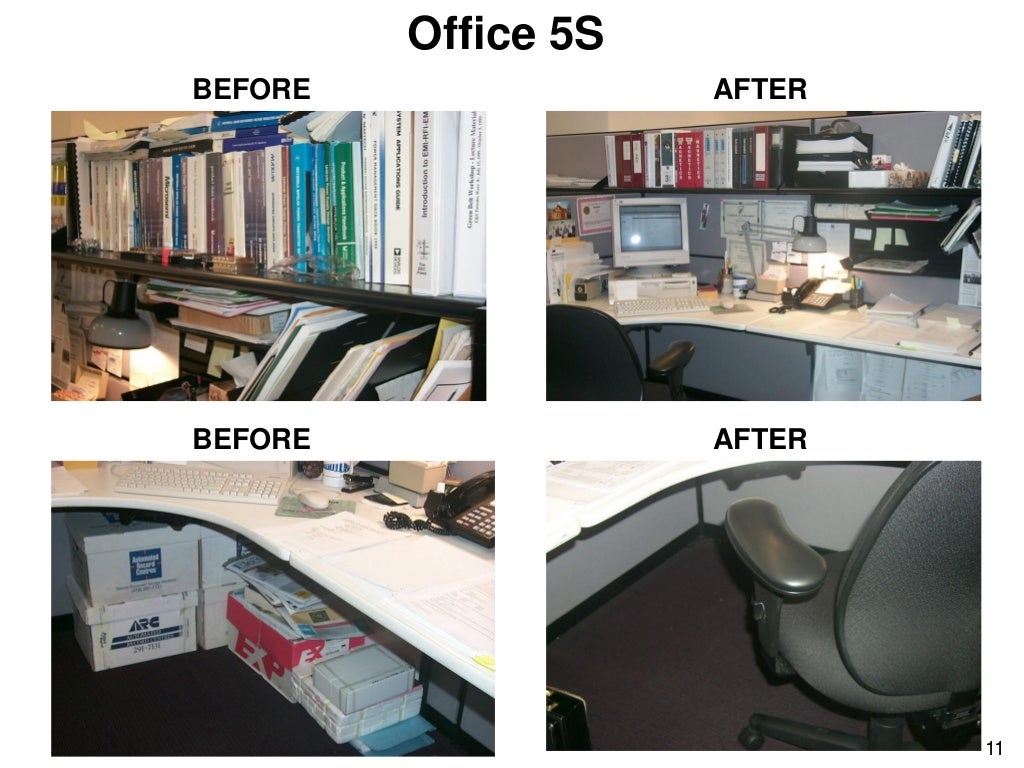

5s For The Office By Operational Excellence Consulting

Best 5s Before After Images Kaizen Lean Manufacturing Lean Six Sigma

5s In The Food Industry Examples And Tips For Implementation Food Safety Magazine

Teach This 5s Process With This 5s Ppt

Learn more about 5S workplace organization.

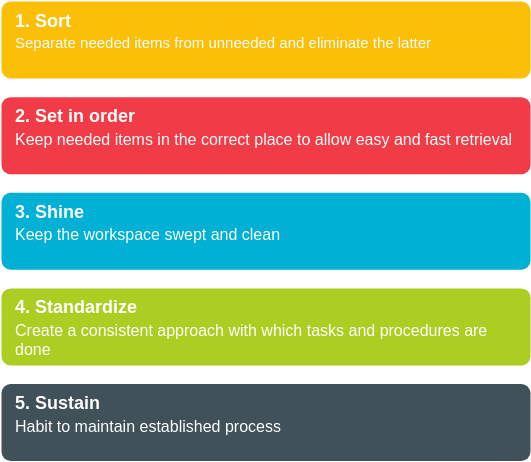

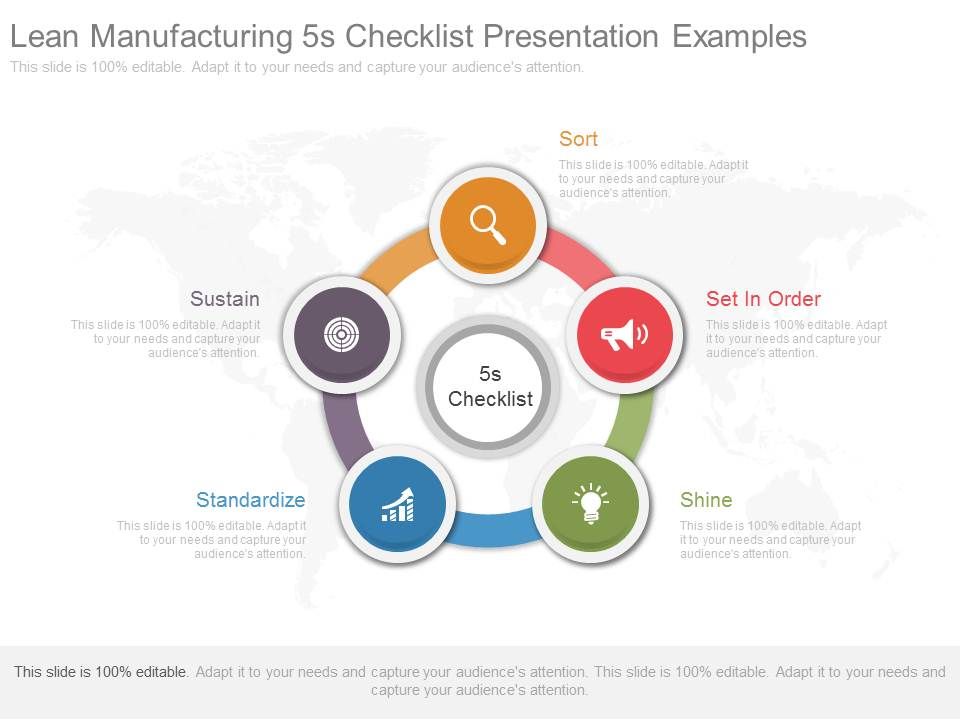

5s examples. This 5S Audit Checklist is a tool used by area supervisors or plant managers to perform monthly or quarterly audits. Workplace scan diagnostic checklist. Column headings include the five housekeeping items of 5S, sort, straighten, shine, standardize, and sustain.

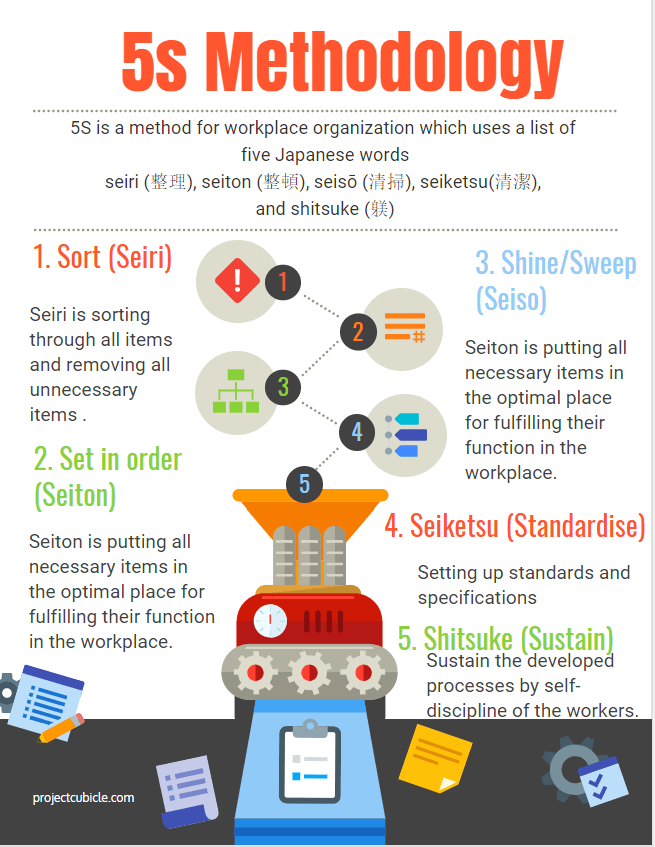

Seiri or sort Seiton or straighten Seiso or shine Seiketsu or. 5S principles reduce waste and increase efficiency. In my personal life, this 5S implementation was my opportunity to replace some bad habits with better ones.

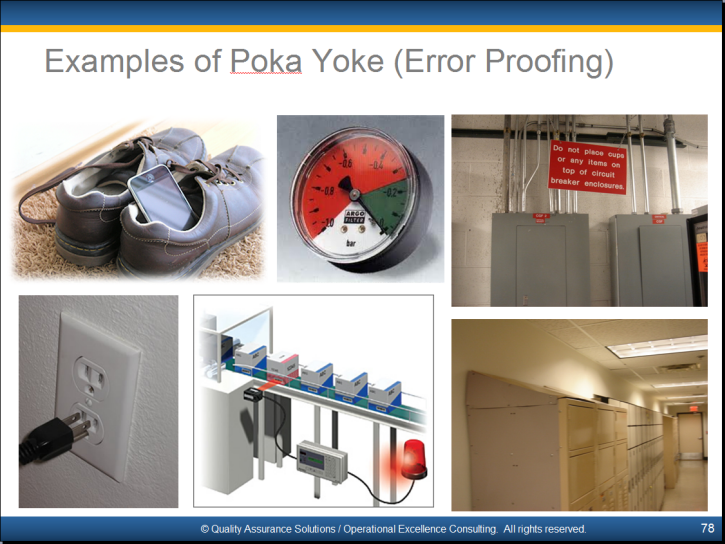

A3 6 Sigma Examples;. 5S (or 6S) is a lean diagnostic technique (developed as a quality management methodology in Japan) aimed at optimization of the workplace environment and efficiency of work performance. The 5S method is an ongoing process that can evolve with time, but the goal remains:.

2 5s methodology stock photos, vectors, and illustrations are available royalty-free. Success stories are being displayed (i.e. 5S “owner” check-sheets should be maintained on daily basis.

What are some examples of 5S strategies?. Naming trivialities aside, though, the purpose of 5S is straightforward:. 5S checklists, schedules and routines are defined and being used.

5S is the perfect tool to identify the first improvement projects in your company to eliminate waste. These are the three of the templates that I have found to be useful once you adjust them to your personal department/company needs. 5S Office Example - Training, Targets, Results Importance;.

Regular audits are carried out using checklists and measures. 5S Audit Area Audit Date Manager Supervisor Category Score Average Sort Straighten Shine Standardize Sustain Total Points 5S Score No. An Example of 5S Let’s take the example of a hospital floor cart.

It is a key concept in Lean Manufacturing and, by extension, in Lean Robotics too. Sample of An Excellent 5s Lean Form. Only the required tools are in the work area.

5S – Training and Coaching. The cumulative results can be major. 5S should be pioneered by a champion or better still a team.

Identify, reduce and eliminate waste Enhance teamwork Enhance operation efffectiveness in a better working environment Form the basic advanced model for Productivity and Quality Improvement. Everyone knows his responsibilities, when and how. Although sometimes viewed as a housekeeping technique, it is actually an innovative management system that helps people think lean, paving the way for the adoption of Lean principles in the organization.

See 5s methodology stock video clips. 5S is a method of work organized in 5 stages with the goal of significantly improving the order and cleanliness. This S goes hand in.

5s are called the working method developed in Japan that has for objective do the workplace be a friendly place, clean, organized, efficient, safe and stimulating. During meetings with internal and external stakeholders, Kaiser Permanente Colorado’s Medicaid Enrollment Project Team used the lean 5S tool to improve the enrollment template, as well as the template process. 5 Japanese words are seiri, seiton, seiso, seiketsu and shitsuke.

See more ideas about Shadow, Custom build, Custom. Isolocity offers an example of how sustaining 5S in the workplace can be automated through software. 5S Transactional Assessment Template & Example.

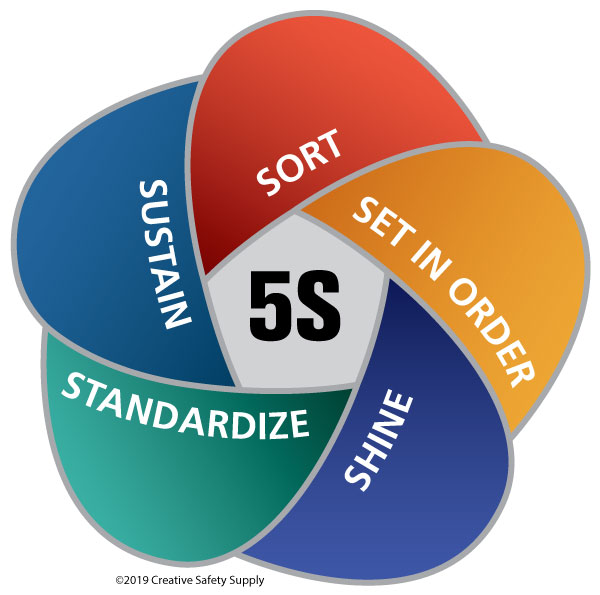

5S is a workplace organization methodology that uses a list of five Japanese words. The 5S workplace organization system was first implemented in Japan as a way to streamline and maintain an efficient work space. 5S Methodology Example 5S Methodology was developed in Japan.

5S (or 6S) technique explained. All required Personal Protective Equipment is in the work area. They’re meant to be followed chronologically and cyclically, as each stage of the practice enables the next and the process as a whole is designed to continually optimize the use of the workspace.

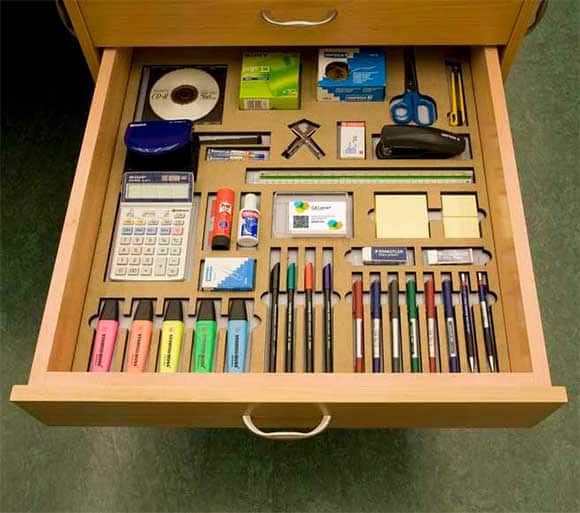

The audit ensures that the 5S program continues indefinitely and a return to old habits does not occur. Example of 5s Checklist for Manufacturing. An office can use 5S to keep supplies organized, as can hospitals and medical clinics.

If you are interested in learning more or having the Process Evaluation and Improvement team facilitate a 5S exercise for your department please contact us at. An example of a check sheet is illustrated in Table 2. Floor Marking and 5S.

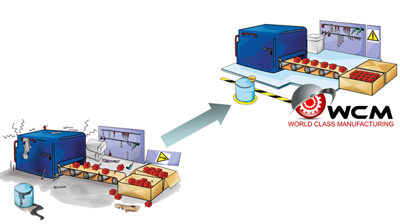

#5sMethodology #5sLeanmanufacturing #shakehandwithlife Download eBooks in PDF 5S Methodology:. DMC started by looking at their engineering process, and considering how things could be done more effectively. Proper implementation will require physical changes to the facility, as well as training employees and other parties to operate in accordance with the 5S methodology.

In order for the 5S to be implemented easily, business organizations come up with an audit form. Add to Likebox # - Kaizen, 5S methodology flat glyph icons set. 5S is a system and way of organizing and managing workspaces to improve efficiency by eliminating waste, improving flow and reducing the number of processes where possible.

It is a system for organizing spaces so work can be performed efficiently & effectively with safely. 5s method 5s practice 5s sort 5s quality kaizen illustraition sort work 5s improvement logo productivity cleaning productivity 5s standardize. • When time is called, count the amount of digits you have crossed off.

Below is an example on how to generate a 5S checklist for manufacturing. It helps create a better working environment and can be implemented to eliminate waste and improve the flow of work. Try these curated collections.

In the 5S Training (Single Module), you’ll learn the basics of these tools and techniques and continue building your problem-solving muscles. What You’ll Get (Certificate, PDUs/CPEs) 5S Manufacturing Assessment Template & Example;. 5S is an approach to achieve a structured and standardized environment whether inside a production plant or anywhere where quick and organized actions are required.

The 5S approach is a way to ensure that your work cell runs at maximum efficiency. Deal with causes of filth and grime. What is 5S Lean?.

The cart connects the nurse on the hospital floor to the supply/store of the hospital for common patient care supplies and special medical care supplies. Another aspect of stabilize for me was to ensure I have a healthy balance between the professional and personal aspects of my life. After an area has been properly sorted out, it is time to set everything in order.

Sort is the first S and is an effort to ensure everything in the workplace is kept in the proper place so that it. It can take quite some time before 5S is fully implemented, but there will be significant. Five S (5S) Example:.

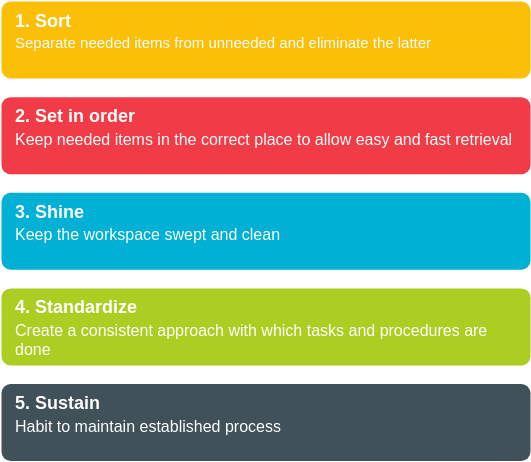

The S's stand for:. Text in this Example:. Only the required materials are in the work area.

Separate out all that is unneeded and eliminate it. To make the workplace more efficient and effective. Sep 29, - Examples of the many custom built shadow boards we create for the workplace!.

Investing in some training for a small number of employees will pay back dividends, as it ensures the technique is applied correctly. 5S as problem-solving philosophy:. • Do not rotate the page.

Far more than colorful lines and simple geometric shapes that help mitigate hazards, floor marking is a useful organizational tool that can prove invaluable for anyone designing a straightforward 5S program.In the same way that floor marking can be used to delineate hazards within the workplace, it can also be used as a vivid visual reminder of where tools should be. Instructions • When instructed, take the activity sheet and cross off as many numbers as you can in the allotted time to represent each cat you have successfully herded. Add to Likebox # - 5s manufacturing improvement tool vector illustration.

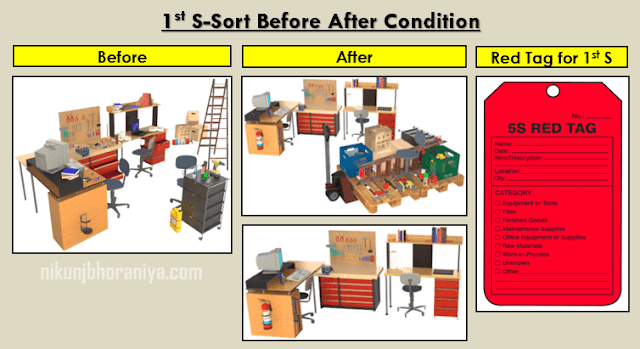

Below is an example of the first 1st ‘S’ (Sort) audit form:. This is a checklist that consists of the 5S in a column and checking of activities under each ‘S’ is done on the other columns. Before and after.

5S audits are often used to evaluate the performance of 5S implementation in any workplace. The intent of the 5S method is to improve efficiency by eliminating waste. 5S workplace (Sort, Set, Shine, Standardize & sustain) examples 1.

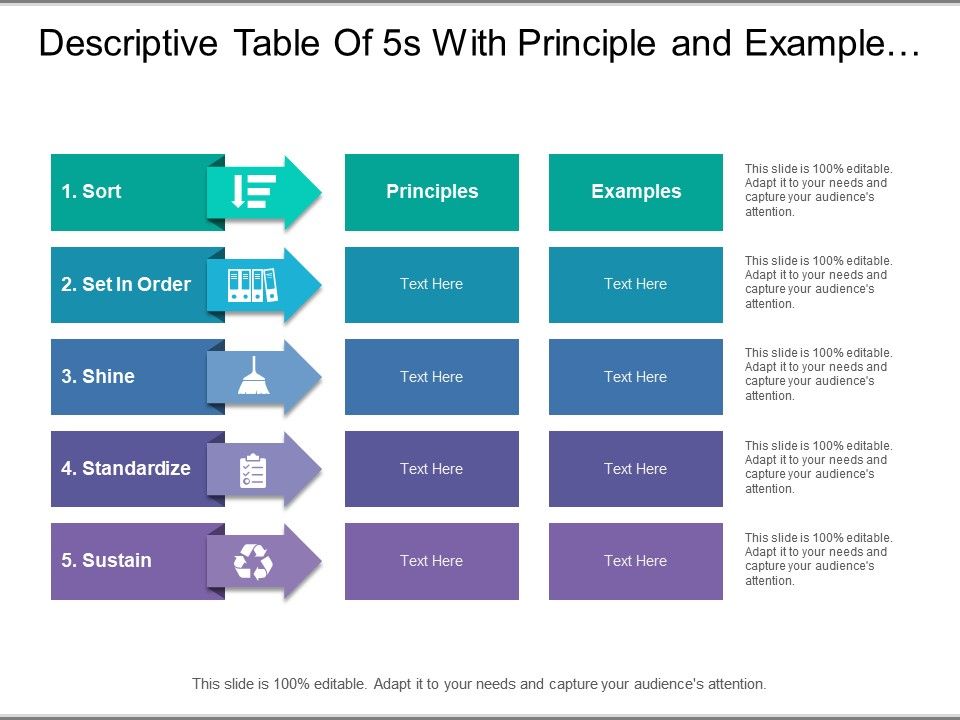

This 5S audit checklist will help ensuring that 5S standards and workplace. The 5S are defined with examples as shown on page 2. Welding RodsTrain ActivitiesSafe StorageWelding MachinePromotional EventsWorking AreaCase StudySignage.

In addition, the opportunity to network and see other examples of successful 5S implementation is invaluable. Lean (JIT) Summary (MAAW web site) 5S Page (CHU) Waste vs Value Added (CHU) Visual Controls (CHU) SMED (CHU) Powerpoint file - 5S Basic Training 5S examples and LEAN terms (large file 1.3M - right click to download). 5S (or 6S) denotes 6 key steps in process improvement:.

Seiri, Seiton, Seiso, Seiketsu, Shitsuke and Safety (Tran, 16). In English, the pillars translate to sort, straighten, shine, standardize, and sustain. ABSTARCT 5S is an important tool within Lean Manufacturing, developed as part of the Toyota Production System (TPS) and Total Productive Maintenance (TPM), it is a highly effective and simple tool.

The methodology of the 5s was developed in the 60's, due to the success achieved during successive years the methodology of the 5s has expanded and implemented in many organizations and businesses of all types, hospitals, banks. How to implement it in project management In order to continually improve, project managers need to regularly communicate best practice processes and standards to the team. 5s is a Japanese methodology.It is the combination of 5s of five word which is started by word S.

1S - SORT Points Area is free of unnecessary clutter. 5S is a Lean technique that involves activities designed to create and maintain a disciplined workplace. Let’s think of existing examples to learn from.

Ever noticed 5S examples outside of a factory?. Put things in order, everything has a place. The key tool for this entrenchment is a detailed regular appraisal of the workplace called the 5S Audit.

Using 5S pillars will take your business to new levels of efficiency.5S is most famously implemented by Toyota in. First column lists action items. Here, I have given the meaning of Japanese word in English.They are-.

• Cross off each number in correct sequence. The basic idea of 5S is that a clean, organized work cell will run much more efficiently than a dirty, disorganized one. Once an organization determines the 5S strategies are a good fit for the company, they need to start planning out how to implement 5S.

What do mean these letters more and more used by companies ?. Kaizen – Make many small changes in the pursuit of continual improvement. 5S systems are common in manufacturing, warehouses, offices and hospitals but 5S principles can be applied to any workplace.

One of the most important part of a sustainable 5S culture is the 5S mini audit ( Panneman, 19 ). Decide how things should be put away, including the. Each S Sort (seiri 整理) Set in order (seiton 整頓) Shine (seiso 清掃) Standardize (seiketsu 清潔) Sustain/self-discipline (shitsuke しつけ).

The standardization process is broken down into five pillars;. 5S must become a way of life, and not just another quick fix program. S5 – Sustain - SHITSUKE:.

Not just the NASA is known for a good 5S approach in their space shuttle program. 5S can even be used in a communal kitchen to keep the fridge from filling up with expired food. Kanban – Use a demand-driven production chain to refocus on customer needs and reduce unnecessary supply stocks,.

Why You Should Register for 5S Training & Certificate. 5S are particularly effective because they want to improve the housekeeping of your workshops and the rest of your premises in order to obtain the following advantages :. (The word owner here is used as a replacement for the title of operator.

An excellent example of 5S comes from Dearborn Mid-West Company (DMC) and their journey to become a lean company. They asked “why” to identify waste and eliminate it (Sort). Meaning of five 5 S:.

They implemented the 5S pillars as follows:. An operator merely operates the machine or process, and might think cleaning is below them. As a 5S audit form, this checklist can help ensure that 5S principles and set standards are being followed and implemented by workers.

In Gemba Kaizen, author Masaaki Imai mentions another method, called 5 C’s (or five-C’s):. 5S seems to be the way of life rather than just a routine. Fantastic example of the first 3 phases of 5S.

5S is a system for instilling order and cleanliness in the workplace. Red – if there is an emergency in process in the first aid room and should not enter, Yellow – if supplies are getting low, the person who restocks the first aid room walks by it everyday going to their office. For example, I committed to saving money by eating at home more frequently instead of eating out.

For each action item, the auditor who analyses the process can grade each item to. 5S is a lean philosophy and a way of organizing and maintaining a clean, high-performance office environment. Total Productive Maintenance – Use preventive maintenance.

# - 5S methodology management with circle arrow line roll diagram.

Visual Management Powerpoint Visual Management Lean Manufacturing Lean Office

Best Practices 5s And Your Warehouse Stickypaper Company

New Year S Resolutions 5 Get Organized Chi Solutions Inc

Best 5s Before After Images Kaizen Lean Manufacturing Lean Six Sigma

Why You Should Launch A 5s Program At Your Workplace Formaspace

5s Methodology Implementation Benefits Case Study

5s Implementation At Superior Ind Example Of The 1st S Sort Lean Six Sigma Visual Management Lean Manufacturing

Five S 5s Training Webinar Brendan Healy Youtube

Bad Lean 5s Hits The Uk Media Lean Blog

5s Lean Manufacturing And Six Sigma Definitions

5s Methodology Principles In Project Management Projectcubicle

5s In The Food Industry Examples And Tips For Implementation Food Safety Magazine

5s Lean Sensei International

Unclutter Your Clutter Introduction To The 5s 1 Visual Workplace

5s Lean Sensei International

3 Tips To Cross Functional 5s Projects Leancor Supply Chain Group Leancor Supply Chain Group

Implementing 5s In Assembly Plants Implementing 5s In Assembly Plants 12 03 01 Assembly Magazine

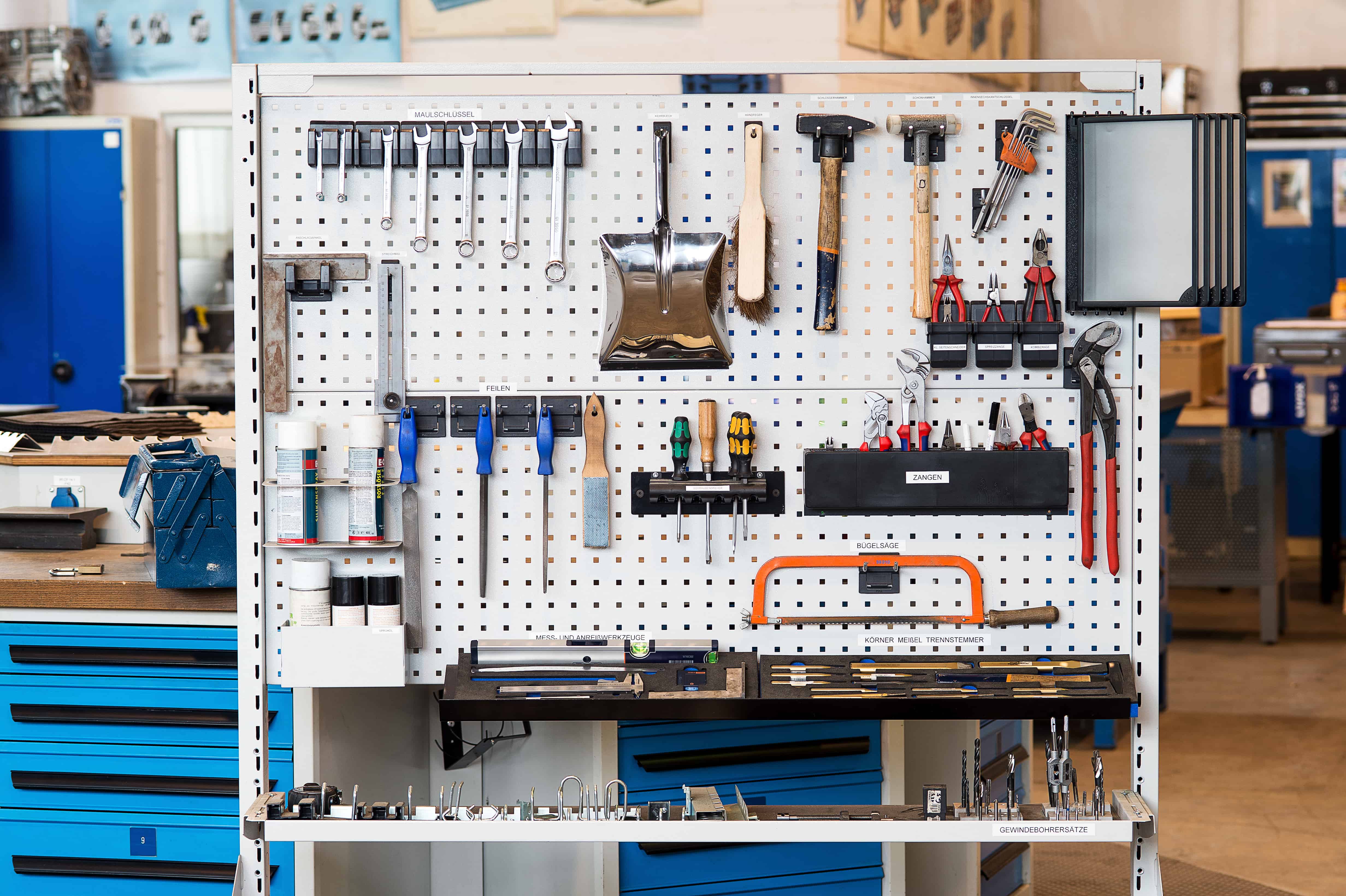

Set In Order Stage Of 5s Helps Companies Find Place For All Items In Workplace Mtec

The 5s System Lean Manufacturing Methodology

Method 5s Explanations And Example Of The 5s Lean Sesa Systems

5s Storyboard By Pullon

What Are Some Examples Of 5s Strategies Creative Safety Supply

Tps Lean Manufacturing Glossary 5s Visual Workplace

5s In Practice Sustain Mudamasters

Best Examples Of 5s Lean Manufacturing Before After Improvements Part 1 Video No 11 Youtube

5s Visual Systems

5s Work Flow Management In Enterprise Excellence Deployment Bpminstitute Org

Lean Manufacturing 5s Checklist Presentation Examples Powerpoint Presentation Slides Ppt Slides Graphics Sample Ppt Files Template Slide

Bad 5s In The Office Allaboutlean Com

5s Organize Your Lean Workspace Get A Free 750 Page Lean Guide

How To Implement Lean Warehousing 5s Practices Legacy

5s Lean Manufacturing And Six Sigma Definitions

Q Tbn 3aand9gcs4td16wgm4mhec2cuvoziy5xbmnibxqqdlroip23vh5gp8ceo6 Usqp Cau

5s Organize Your Lean Workspace Get A Free 750 Page Lean Guide

Neatness Counts At Kyocera And At Others In The 5s Club Wsj

What Is 5s Lean Safetyculture

5s Methodology Wikipedia

How To Implement 5s In The Workplace Kanban Zone

5s Implementation In The Workplace Observer

How To Implement The 5s Approach In Workcells Workstations Cisco Eagle

How To Create A Culture To Sustain 5s Industryweek

5s Shine Real Example

Using The 5 S S Seiri Seiton Seiso Seiketsu And Shitsuke Toughnickel Money

5s For The Office By Operational Excellence Consulting

Industrial Knowledge Complete Tutorial Of 5s Methodology Explained With

The 5s System Lean Manufacturing Methodology

5s Sort Set In Order Shine Standardize Sustain 13 06 07 Ishn

5s Examples In Action The Good The Bad Graphic Products

Different Approaches In The 5s Implementation Performance Storyboard

Importance Of 5s In Six Sigma Quality Management

Examples Of Applications Of 5s In Your Organization Download Scientific Diagram

5s Case Study Using Toyota S 5s On A Farm The Lean Farm By Ben Hartman Book Review Econoshift Com

What Are Some Examples Of 5s Strategies Creative Safety Supply

5s Set In Order Real Example

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

5s Visual Systems

5s Certification

5s Methodology

5s Course Business Performance Improvement Bpi

Office 5s Before After Before

5s Training Qualitytrainingportal

5s At Trumpf Allaboutlean Com

Http Www Intracen Org Uploadedfiles Intracenorg Content Exporters Exporting Better Quality Management Assetpdf Bulletin eqm 5s Pdf

8 Best 5s Examples Images Train Activities Visual Management Working Area

5s Examples Fred Webberking

%20-%20Bad%20-%20Clutter%20in%20Corner%20of%20Factory.jpg)

Bralla Com Lean Manufacturing

5s And Visual Workplace Essential For Sustaining Lean Manufacturing

5s The Good The Bad And The Extreme In Japanese Hospitals Lean Blog

Teach This 5s Process With This 5s Ppt

5s Lean Manufacturing How To Implement It For Success

10 Tips For Greening Your 5s Workplace Organization Events Earth Consultants

Lean 5s Seiri Sort Clearing Classify

Some Images Of 5s Houskeeping In Factories Total Quality Management

Q Tbn 3aand9gctn9uzxykdentoilhtllyxvy4qhdjekcm278l0rkcxf1wsjnu J Usqp Cau

5s Lean Manufacturing And Six Sigma Definitions

6 Tips On How To Implement A Lean Office In The Aec Industry

What Is The 5s System Definitions Core Concepts Principles Graphic Products

The 5s Approach To Improve A Working Environment Can Reduce Waiting Time Findings From Hospitals In Northern Tanzania Emerald Insight

5s Seiketsu Standardize And Visual Management Fastening Supply And Inventory Management Falcon Fastening Solutions

5s Lean Workspace 5s Example

Descriptive Table Of 5s With Principle And Example Of Different Categories Of Sort Shine Standardize And Sustain Ppt Images Gallery Powerpoint Slide Show Powerpoint Presentation Templates

Tps Lean Manufacturing Glossary 5s Visual Workplace

5s Basic Training What Is 5s And Why Do We Want To Do It Ppt Video Online Download

5s Safety Lean 6s Safety Convergence Training

5s Home Page

5s In The Laboratory What Why How

S3 Eu West 1 Amazonaws Com Pfigshare U Files 5s Presentation Pdf

The Importance Of 5s Manufacturing Net

5s Lean Manufacturing How To Implement It For Success

8 Best 5s Examples Images Train Activities Visual Management Working Area

Examples Of Applications Of 5s In Your Organization Download Scientific Diagram

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

Just 5s It My Lean Kitchen

Shitsuke Is The Fifth And Final Step Of The 5s Method

5s Lean Manufacturing And Six Sigma Definitions

5s Examples In Action The Good The Bad Graphic Products

3

Q Tbn 3aand9gcsidugv12uodonhwvmjwqxdbnokyod6zlecjvzk2hm Hqizxddz Usqp Cau